Prefabricated pier and bearing platform connected structure and butt joint construction method thereof

A bridge pier and structure technology, which is applied in the connection structure of prefabricated bridge piers and caps and its butt joint construction, can solve the problems of prolonging the construction period of bridges, and achieve the effects of improving durability, enhancing shear resistance, and facilitating construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

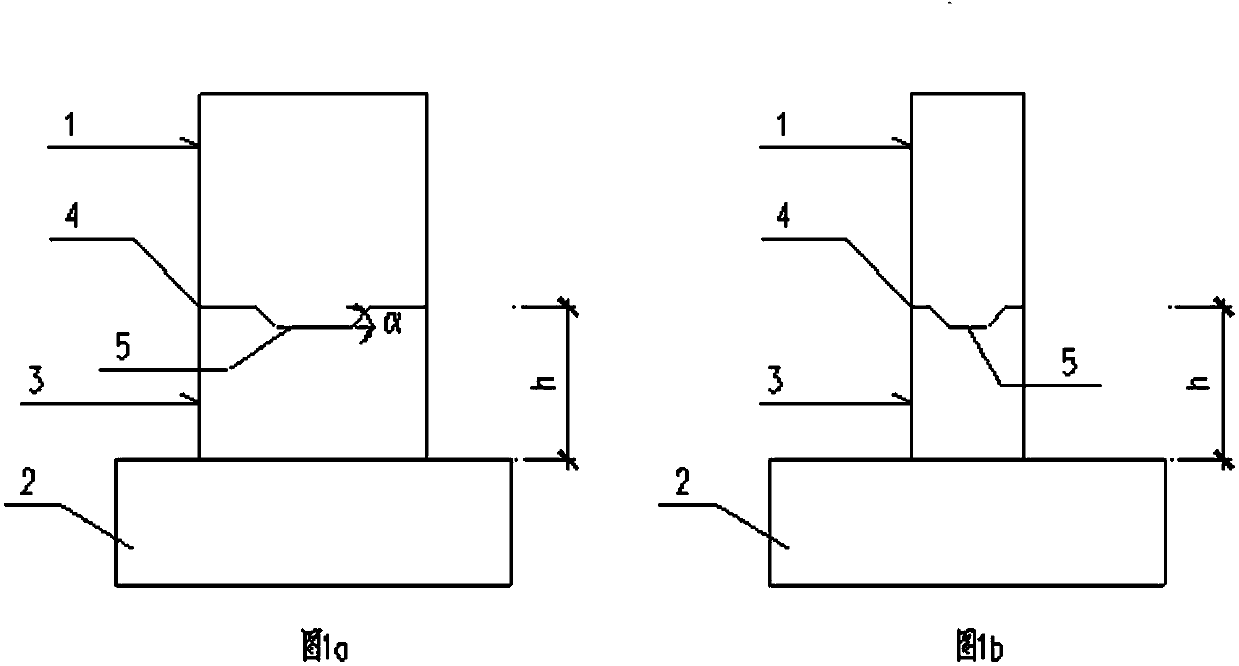

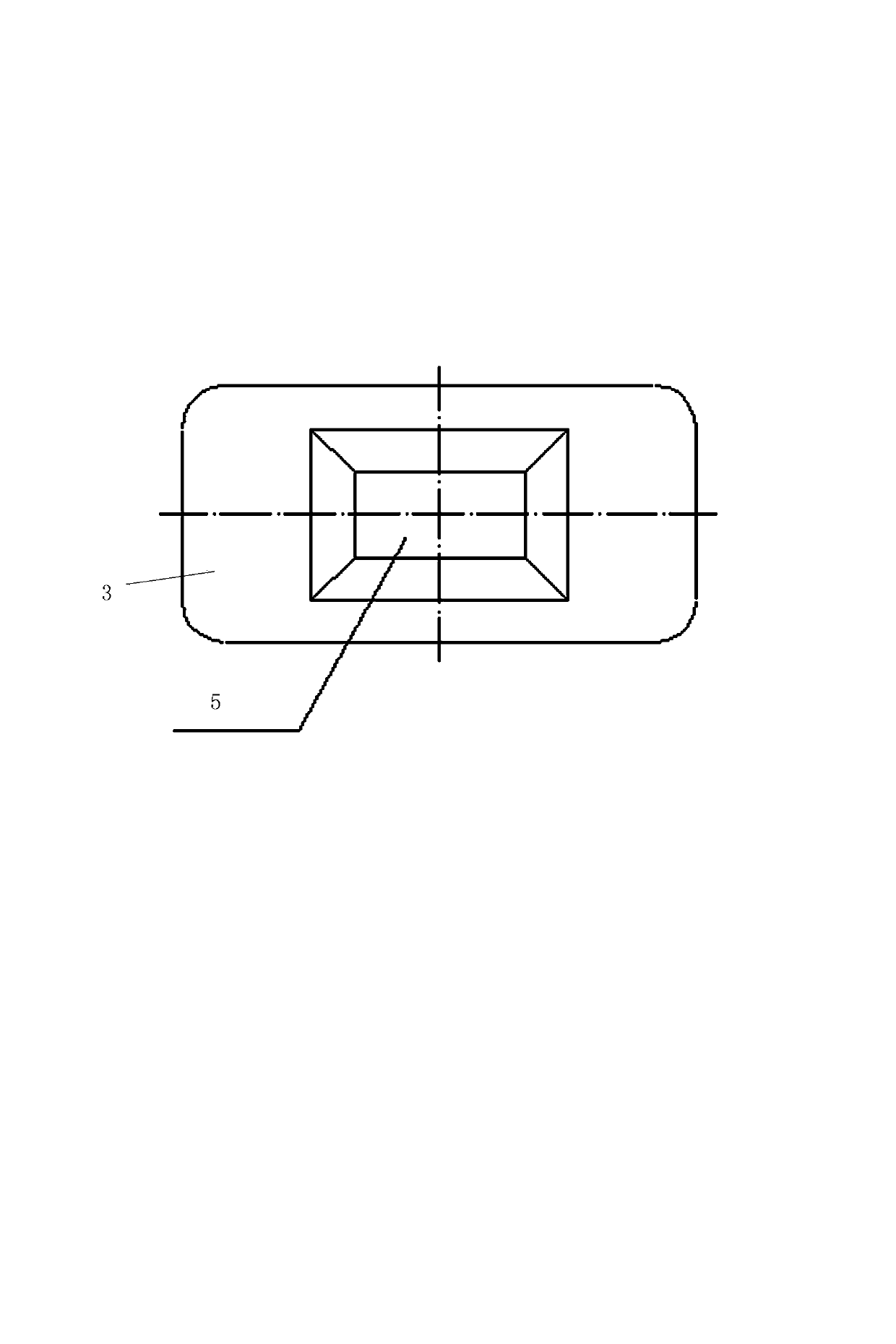

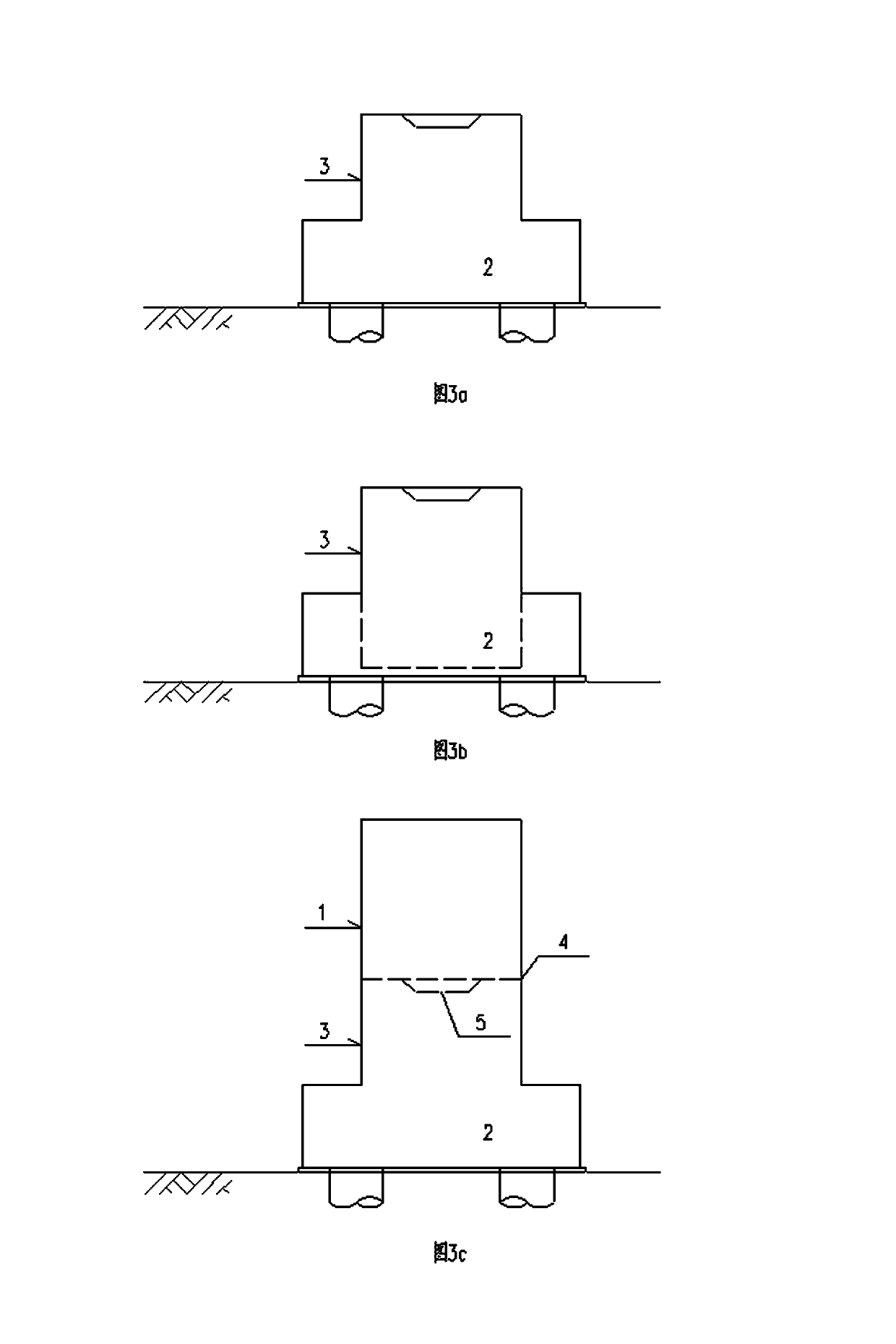

[0014] A connection structure between a prefabricated pier and a cap, characterized in that the pier includes a prefabricated pier body 1 and a pier body bottom connection section 3, and a shear key 5 is set at the bottom of the prefabricated pier body 1, wherein the pier body bottom connection section 3 can be It can be poured together with the cap 2, or it can be prefabricated. Set the reserved steel bar at the lower part of the connection section to connect with the cap reinforcement, and then pour the cap, and set the top surface of the connection section 3 at the bottom of the pier body to match the bottom of the prefabricated pier body 1. The shear key 5, the connecting section 3 at the bottom of the pier body and the prefabricated pier body 1 are connected through the shear key 5 that cooperates with each other. The connecting section 3 at the bottom of the pier body and the prefabricated pier body 1 are vertically connected by prestressed steel bars or ordinary steel ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com