Curve or distortion detection and prestressing force infliction experiment table for composite material C-type beam

A technology of composite materials and test benches, applied in the directions of analysis materials, measuring devices, instruments, etc., can solve the problems of difficulty in overall molding and difficult correction of manufacturing deviations, so as to improve production efficiency and quality, shorten inspection cycles, and save costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The embodiments of the present invention are described in detail below: this embodiment is implemented under the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided. It should be noted that those skilled in the art can make several modifications and improvements without departing from the concept of the present invention, and these all belong to the protection scope of the present invention.

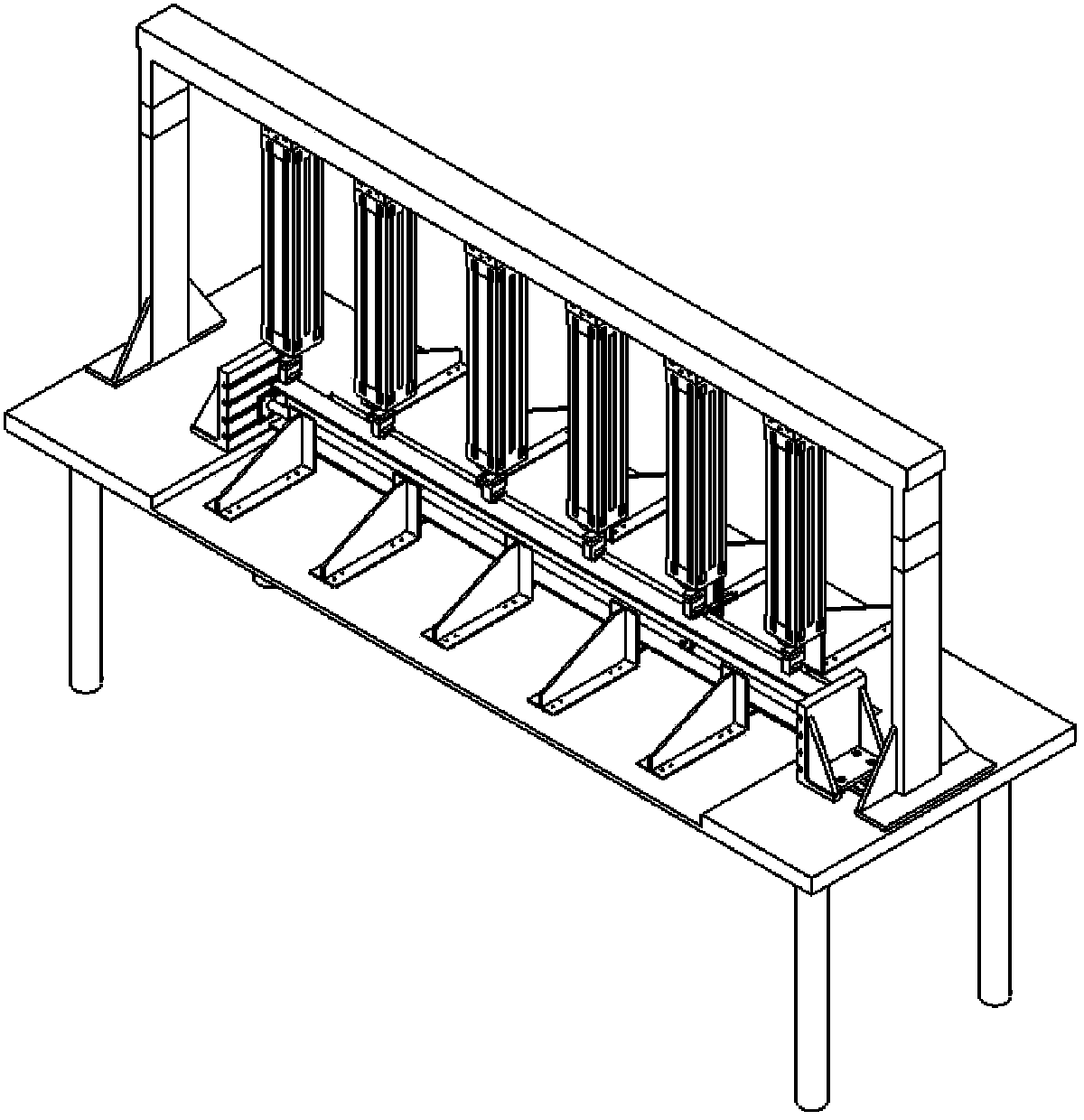

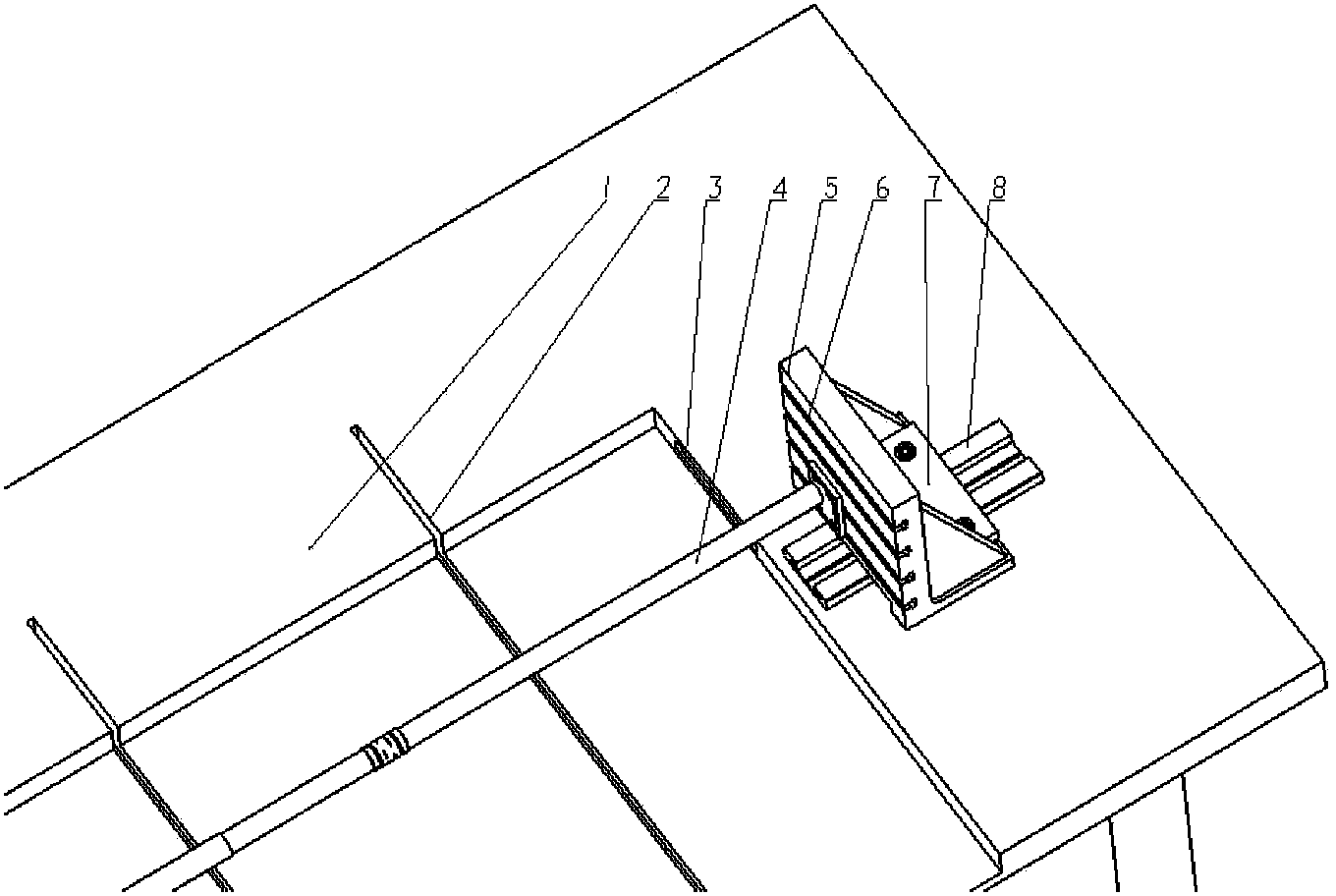

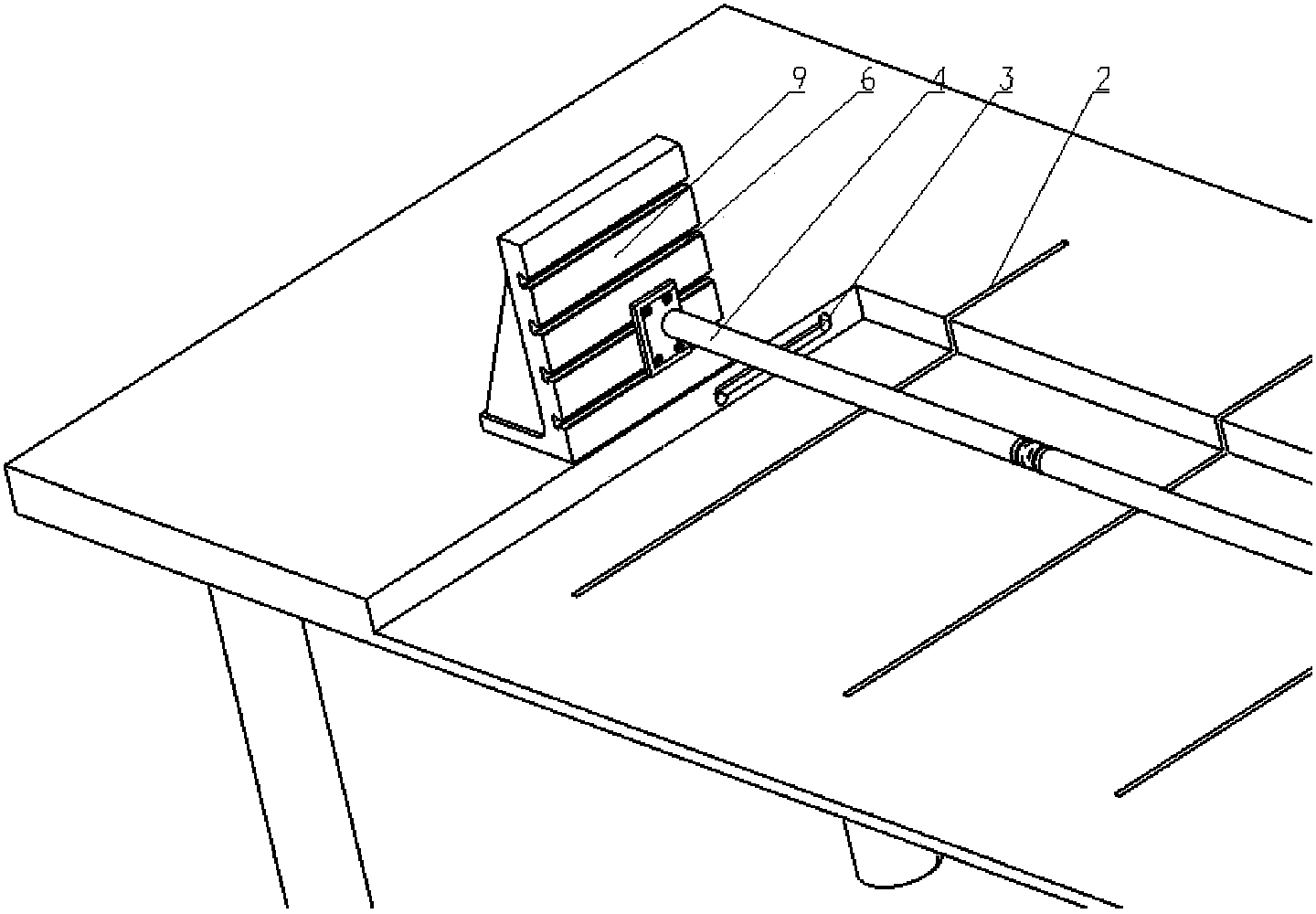

[0027] Please also see Figure 1 to Figure 7 .

[0028] This embodiment provides a composite C-beam bending and twist detection and prestressing test platform, including: the bottom platform of the test platform, a longitudinal positioning block and a force applying device installed on the bottom platform of the test platform, and the left side of the edge The horizontal positioning device, the horizontal clamping device on the right side of the edge and the longitudinal positioning device,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com