Liquid distribution equipment

A technology for dispensing equipment and equipment, which is applied to liquid ejection devices, analytical materials, ejection devices, etc., can solve the problems of uneven performance of liquid reagents and high costs, and achieve the effects of symmetrical lines, cost savings, and reduction of zigzag structures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In conjunction with the accompanying drawings, the structure of the present invention and the specific technical solutions used will be further described below. These descriptions are only limited descriptions of some implementations of the present invention, and do not constitute further limitations on the claims required by the present invention.

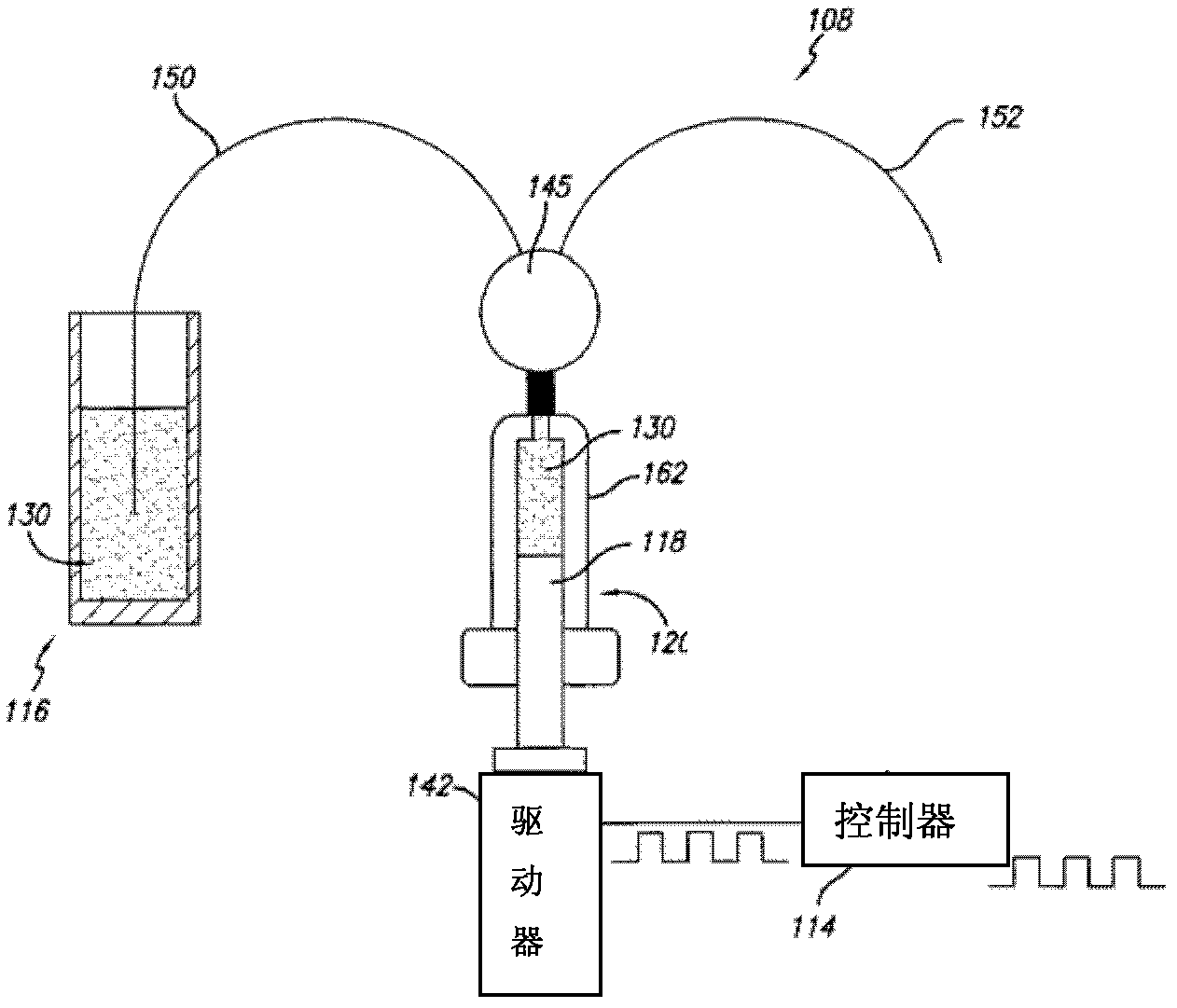

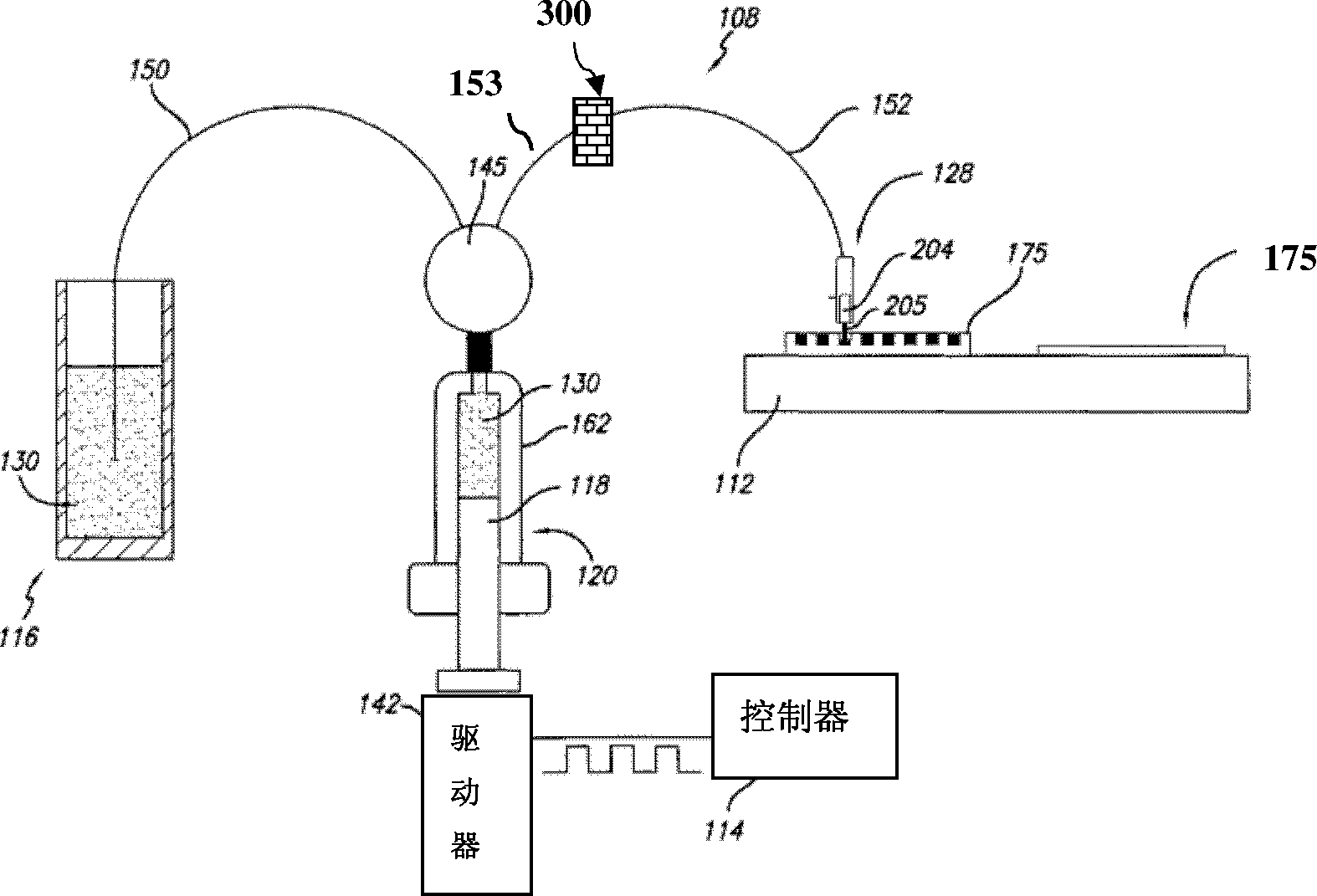

[0030] figure 1It is a specific operation mode of the traditional liquid dispensing device 108. In this embodiment, the pump can be a commonly used syringe pump 120, which is automatically driven by a driver 142. The motor or servo motor drives the piston 118 in the syringe pump to move back and forth in the piston barrel 162 . Those of ordinary skill in the art know that when the piston 118 is withdrawn, such as moving downward, the liquid 130 located in the liquid storage chamber 116 enters the inside of the syringe pump 12 through the switching valve 145. When the piston 118 is propelled, such as moving upwards, the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com