Preparation method of blue glass infrared cut filter

A technology of infrared cut-off and infrared cut-off film, which is applied in the fields of filters, optics, optical components, etc., can solve the problems of low production yield of blue glass infrared cut-off filters, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The method for preparing the above-mentioned blue glass infrared cut-off filter will be further elaborated below through specific embodiments.

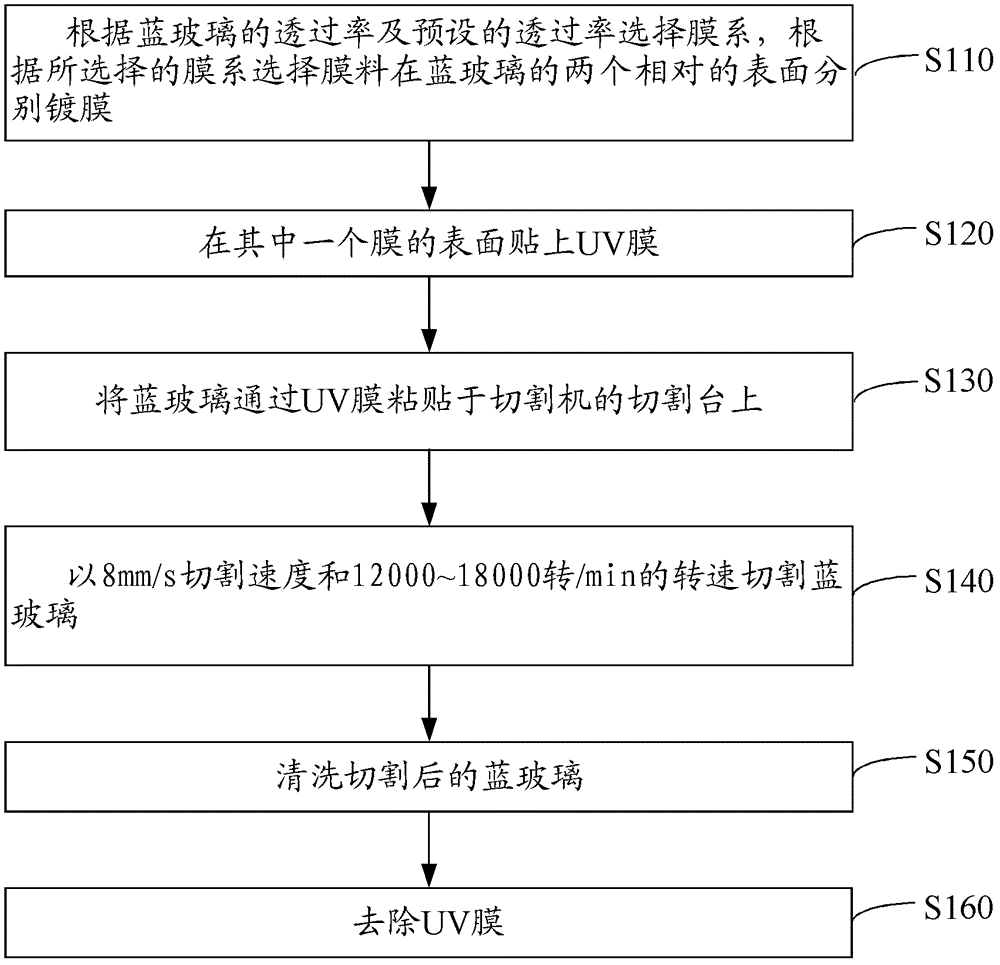

[0020] see figure 1 , the blue glass infrared cut-off filter preparation method of one embodiment, comprises the steps:

[0021] Step S110: Select a film system according to the transmittance of the blue glass and a preset transmittance, and select film materials according to the selected film system to coat the two opposite surfaces of the blue glass respectively.

[0022] In this embodiment, a vacuum evaporation method combined with an ion-assisted deposition method is used to coat two opposite surfaces of the blue glass. The film material is evaporated from the heat source or electron beam heating source, and the deposited molecules or atoms are continuously bombarded by ions from the ion source, thereby obtaining greater momentum, which is conducive to increasing the aggregation density of the film, improving the compactne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com