A kind of cleaning method of diamond wire cut crystalline silicon wafer

A diamond wire cutting and crystalline silicon wafer technology, which is applied in the directions of cleaning methods, cleaning methods and utensils, chemical instruments and methods using liquids, etc., can solve the problem of increasing the fragmentation rate of crystalline silicon wafers, inability to separate crystalline silicon wafers, and difficulty in slicing and other problems, to achieve the effect of reducing the fragmentation rate, reducing the edge collapse rate, and shortening the process time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

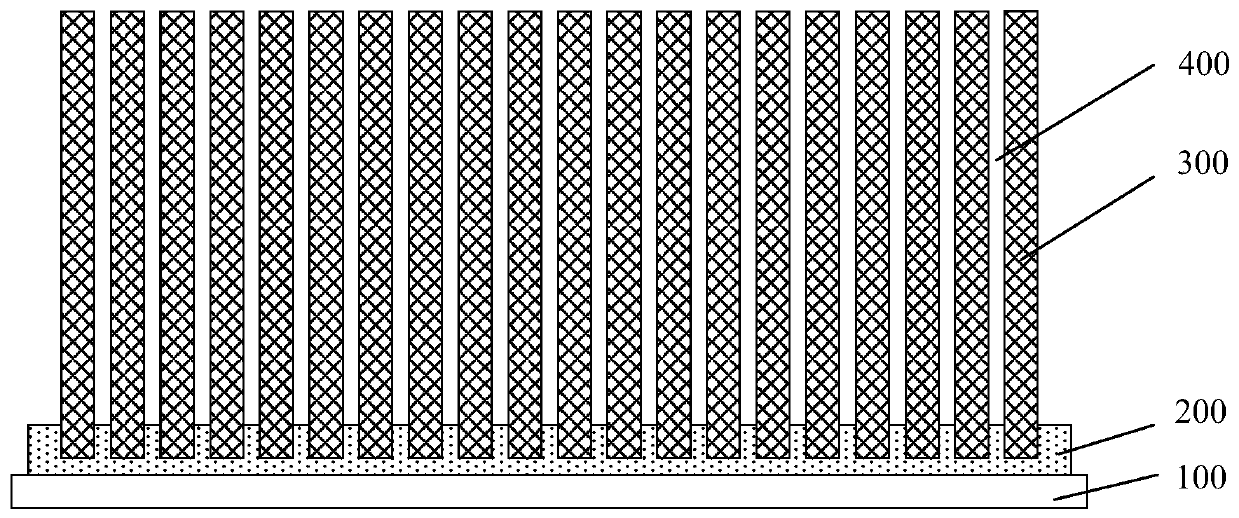

Image

Examples

Embodiment 1

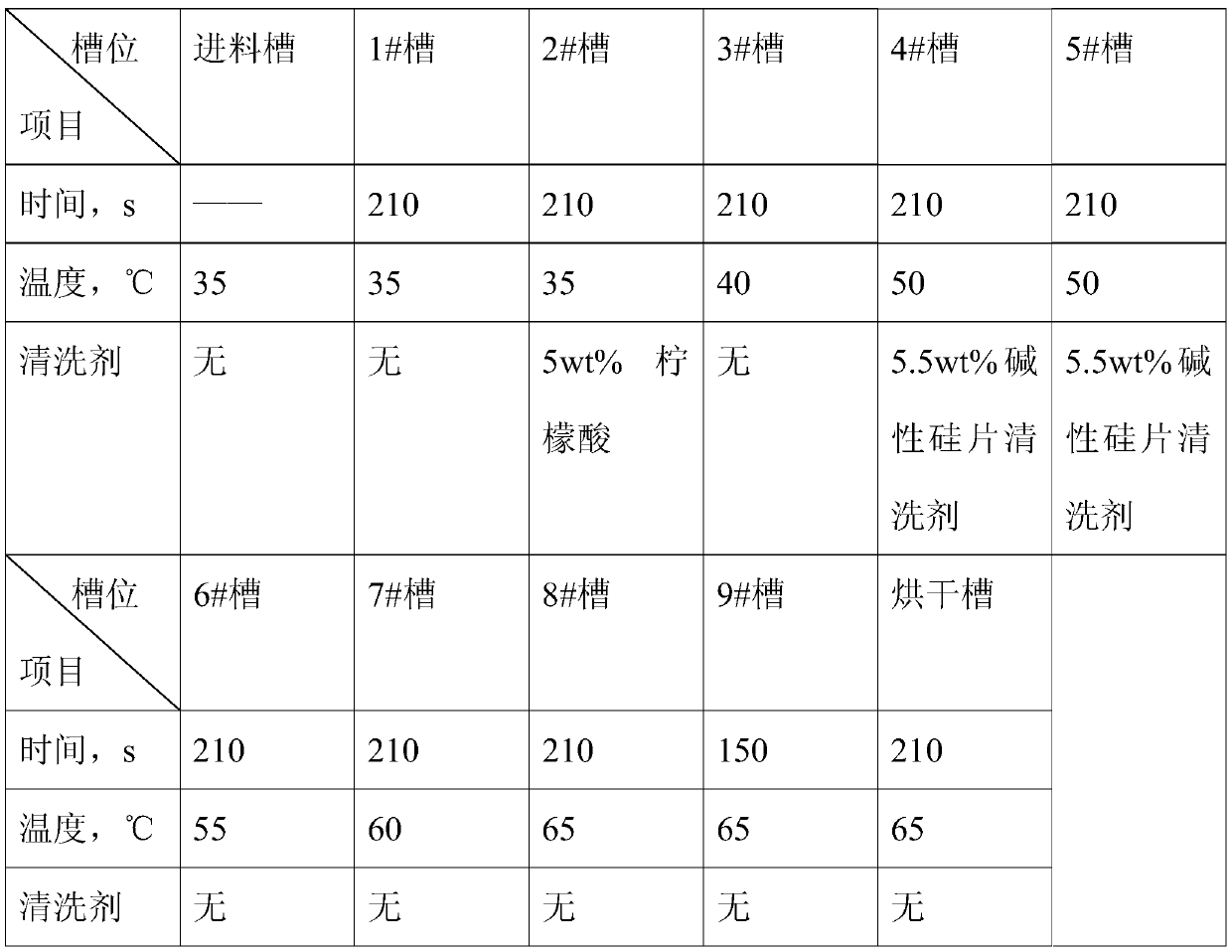

[0063] Embodiment 1 provides a kind of cleaning method of the crystalline silicon of diamond wire cutting, comprises the steps:

[0064] (1') Slicing the ingot in a fully automatic chip cleaning agent, peeling off the crystalline silicon chip with horizontal force, and inserting the chip to obtain a tooling including the crystalline silicon chip;

[0065] (1) placing the tooling of step (1') including the crystalline silicon wafer in the first washing tank with pure water, to carry out the first pre-cleaning;

[0066] (2a) placing the tooling including the crystalline silicon wafer in step (1) in the second washing tank equipped with an acid cleaning agent, and performing acid cleaning; the acid cleaning adopts citric acid;

[0067] (2b) placing the tooling including the crystalline silicon wafer in step (2a) in the third washing tank equipped with pure water, and washing with water;

[0068] (2c) Place the tooling including the crystalline silicon wafer in step (2b) in the f...

Embodiment 2

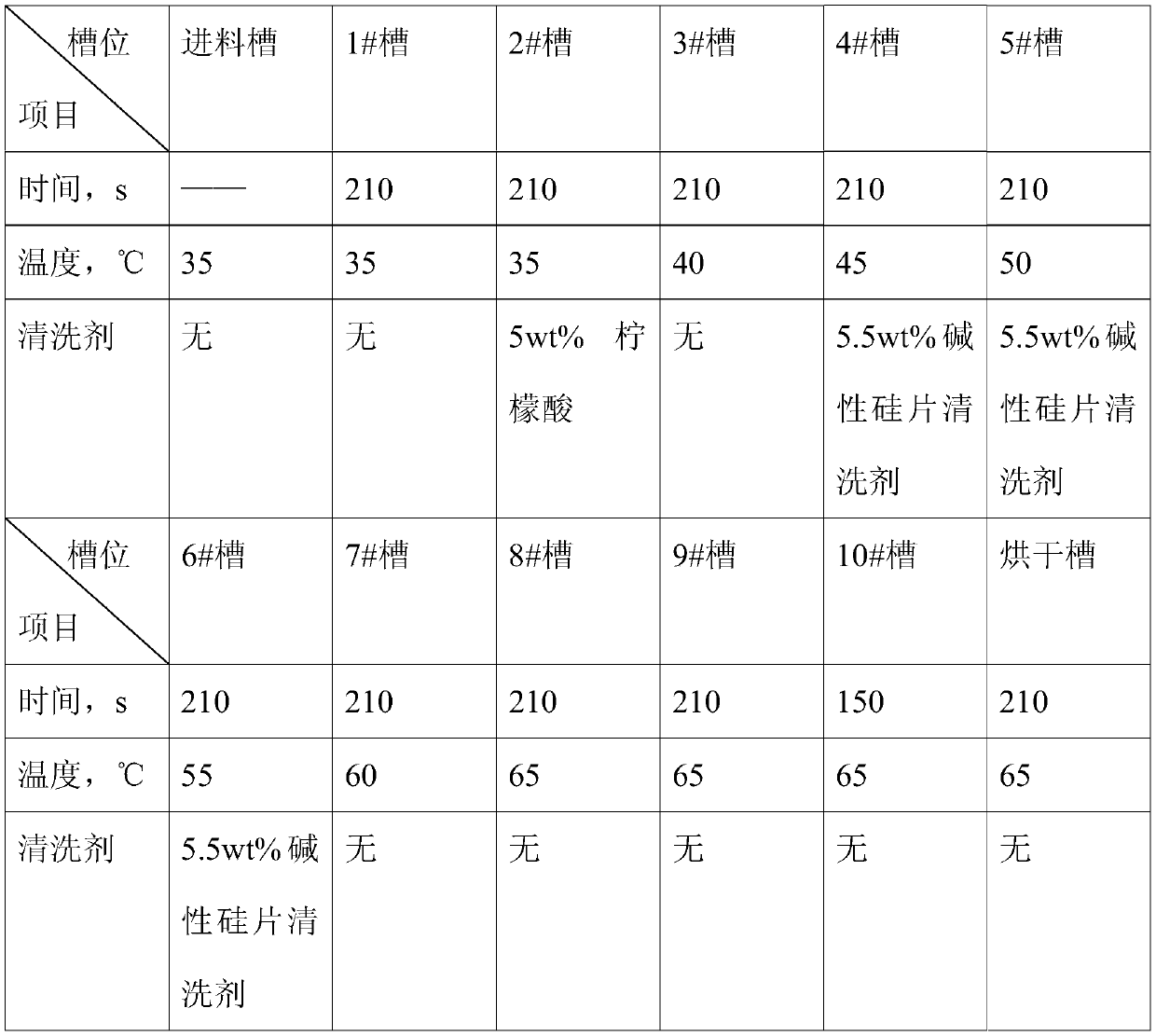

[0077] Embodiment 2 provides a kind of cleaning method of the crystalline silicon of diamond wire cut, and the difference with embodiment 1 is: carry out step (3e) between step (3d) and step (4) and step (3d) comprises crystal The tooling of the silicon wafer is placed in the tenth washing tank filled with pure water for the fifth rinse;

[0078] Afterwards, step (4) is carried out, and the workpiece including the crystalline silicon wafer in step (3e) is dried at 65°C.

[0079] Adopt the above-mentioned method to carry out the cleaning of crystalline silicon chip, the concrete technological condition of step (1)~(4) is as follows, and the washing quantity is 19000~20000 pieces:

[0080]

Embodiment 3

[0082] Provided is a method for cleaning diamond wire-cut crystalline silicon, comprising the steps of:

[0083] (1') Slicing the ingot in a fully automatic chip cleaning agent, peeling off the crystalline silicon chip with horizontal force, and inserting the chip to obtain a tooling including the crystalline silicon chip;

[0084] (1) placing the tooling of step (1') including the crystalline silicon wafer in the first washing tank with pure water, to carry out the first pre-cleaning;

[0085] (2a) Place the tooling including the crystalline silicon wafer in step (1) in the fourth washing tank equipped with a cleaning agent, and perform the first alkali cleaning; the alkali cleaning uses Sanda Oak silicon wafer cleaning agent;

[0086] (3a) placing the tooling including the crystalline silicon wafer in step (2a) in the sixth washing tank equipped with pure water, and rinsing for the first time;

[0087] (3b) placing the tooling including the crystalline silicon wafer in step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com