Silicone wafer degumming pre-washing device

A silicon wafer degumming and pre-rinsing technology, applied in the direction of cleaning methods using liquids, cleaning methods and utensils, cleaning methods using tools, etc., can solve problems such as chipping of silicon chips, reduce energy consumption, and reduce the rate of edge chipping , Reduce the effect of glue cold and heat shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The above descriptions are only preferred embodiments of the present invention, and are not intended to limit the present invention.

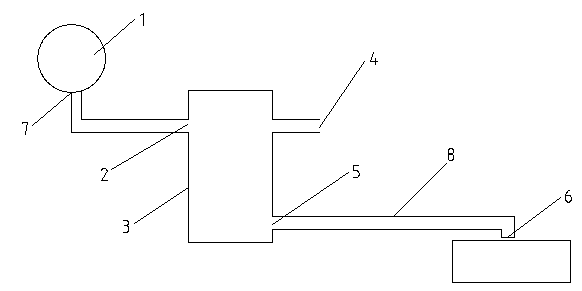

[0013] Such as figure 1 As shown, the two sides of the upper end of the plate heat exchanger 3 are respectively provided with a first inlet 2 and a second inlet 4, the first inlet 2 is connected to the outlet 7 of the cooling water 1 of the ingot furnace, and the second inlet 4 is a cold water injection port. The lower end of the heat exchanger 3 is provided with an outlet 5 of the plate heat exchanger, which is connected with the silicon wafer pre-flush pipeline 8 , and the pre-flush port 6 is arranged at the other end of the silicon wafer pre-flush pipeline 8 .

[0014] When in use, the heat generated during the heating process of the ingot furnace is passed through the cooling water, and the cooling water of the ingot furnace (at a temperature of 30°C) is transferred to the plate heat exchanger through the first inlet 2, and at the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com