A mask table for exposure device

A technology of exposure device and mask stage, applied in the field of mask stage, can solve problems such as difficult application and large object distance of objective lens, etc., and achieve the effects of solving compatibility problems, improving use scalability, and reducing the complexity of structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

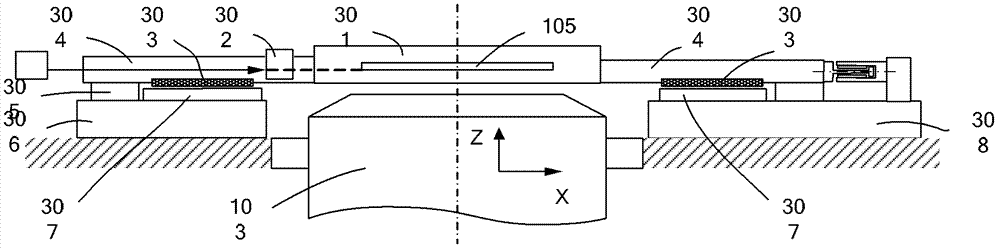

[0037] The invention provides a mask stage of a splicing lens exposure device with a large field of view, which has the functions of horizontal precision fine-tuning and large-stroke scanning movement, and has the functions of mechanical pre-alignment and compatibility with large and small reticles.

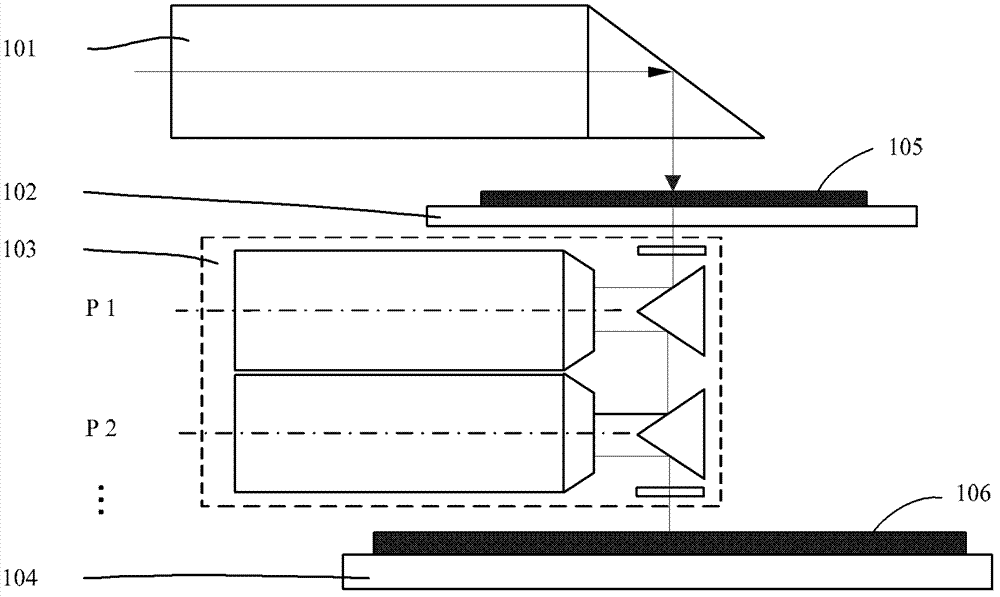

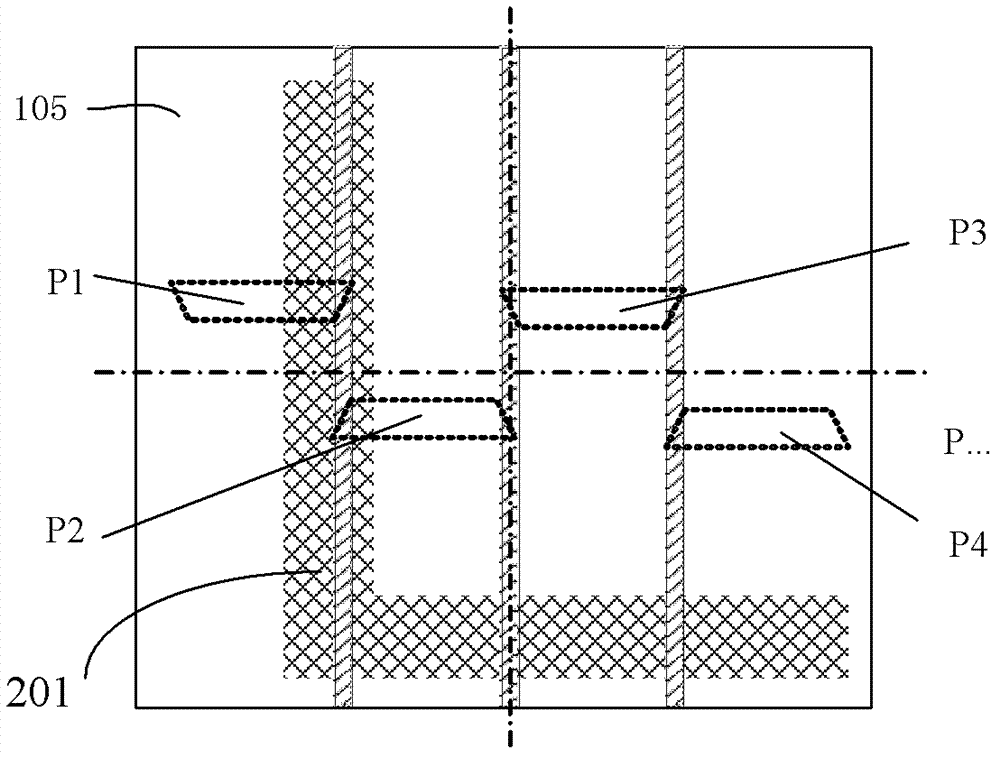

[0038] figure 1 It is a structural schematic diagram of the splicing exposure device. It can be seen from the figure that the splicing lens exposure device mainly includes an illumination system 101 , a mask stage 102 , a projection objective lens 103 , and a substrate stage 104 . The illumination system 101 is located above the mask table 102 and provides exposure light source for the exposure device. The mask table 102 supports and posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com