Method and system for testing low-voltage differential signals

A low-voltage differential signal and test system technology, applied in electronic circuit testing, semiconductor/solid-state device testing/measurement, electrical measurement, etc., can solve problems such as error-prone, unable to meet the competitive needs of fast and high-quality production, and low efficiency. Achieve the effect of meeting competitive demands, eliminating test result errors, and shortening test time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In this application, exemplary embodiments will be described around a real-time error correction system and a navigation device using the system. Those of ordinary skill in the art should realize that the following description is only exemplary and not intended to be limiting in any way. Inspiration for other embodiments will readily occur to those skilled in the art having the benefit of this application. Now, implementation of the exemplary embodiments as shown in the accompanying drawings will be described in more detail. Wherever possible, the same reference numbers will be used throughout the drawings and the following description to refer to the same or like items.

[0034] Reference will now be made in detail to the preferred embodiments of the invention, examples of which are illustrated in the accompanying drawings.

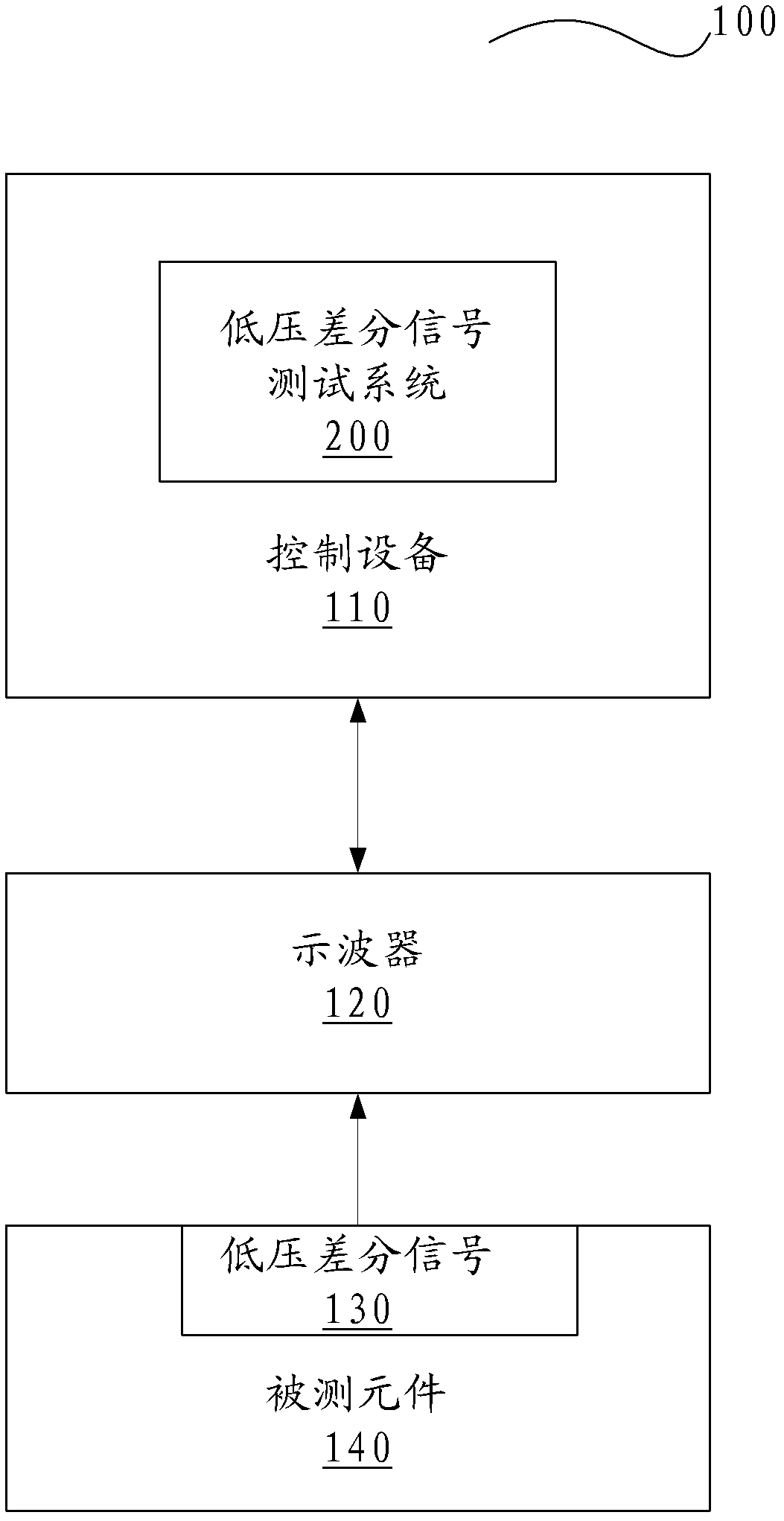

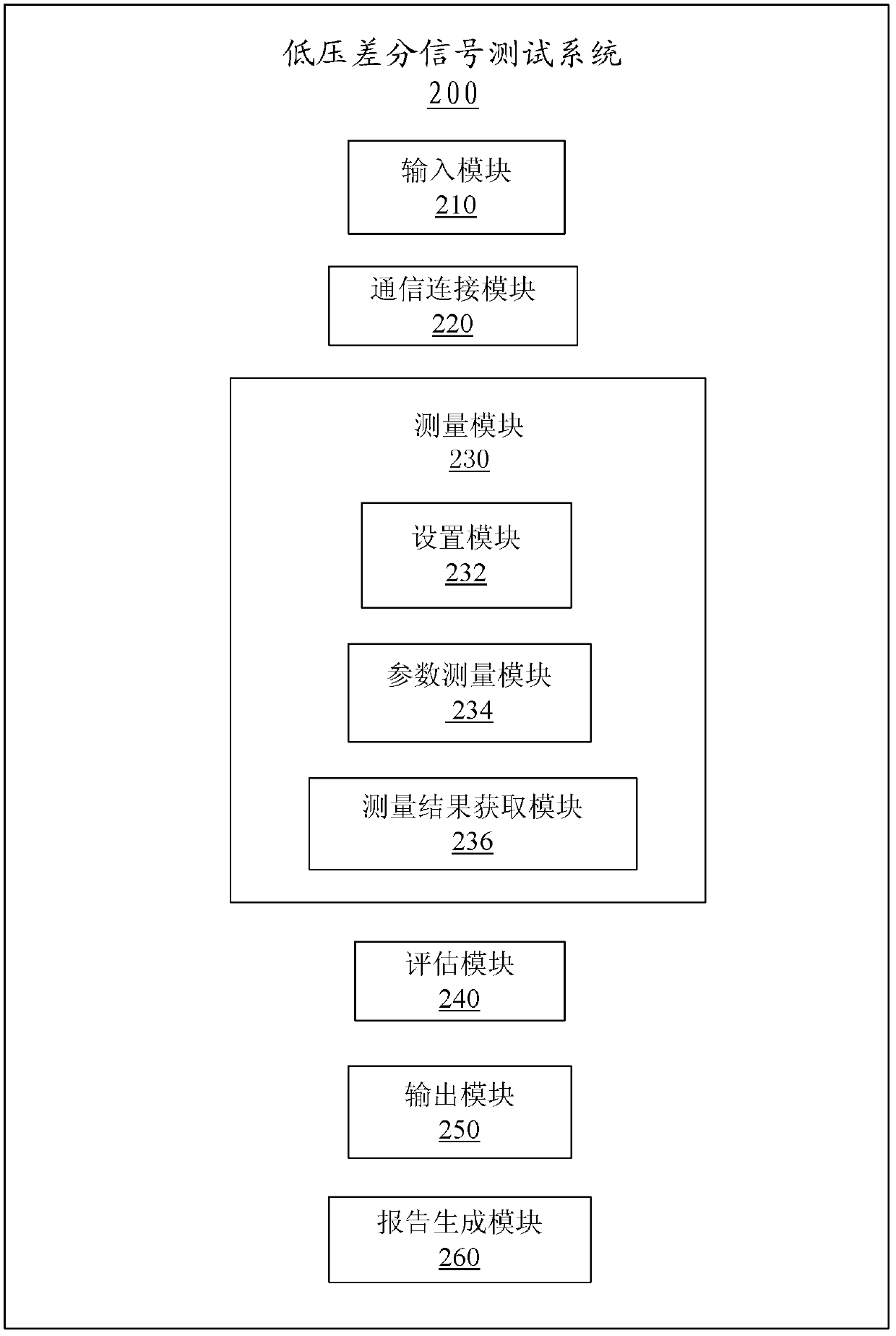

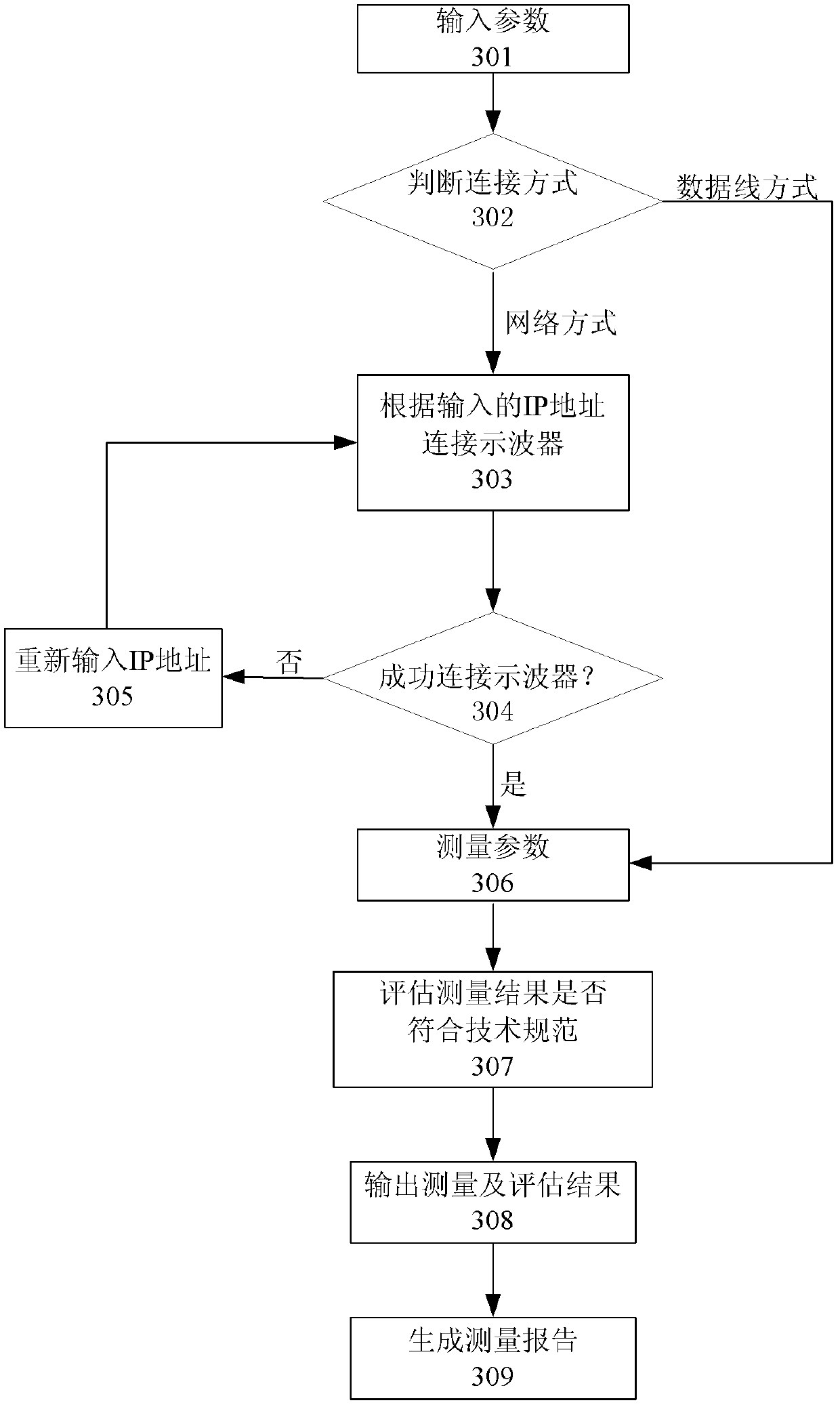

[0035] One aspect of the present invention provides a low-voltage differential signal test system 200. The signal test system can efficiently t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com