Material grinder

A pulverizer and material technology, applied in the direction of grain processing, etc., can solve the problems of lack of separation mechanism for coarse and fine materials, difficulty in fully pulverizing materials, and increased workload of personnel, so as to reduce workload, more fully pulverize, and improve pulverization efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

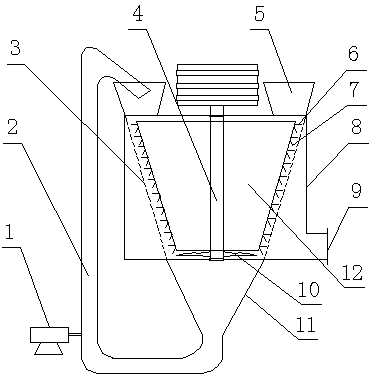

[0018] Such as figure 1 Shown: a material pulverizer, including a casing 8, an inverted frustum-shaped rotating body 12 and an inverted frustum-shaped filter support 3 are arranged in the casing 8, and the rotating body 12 is flexibly connected with the casing 8 through a main shaft 4 A fixed blade 6 and a movable blade 7 are arranged on its peripheral side, the filter support 3 is fixedly connected to the casing 8, and a funnel-shaped slag drop communicating with the filter support 3 is provided at the bottom of the casing 8. Hopper 11, the top of the casing is provided with a material feed port 5 and a slag feed port respectively, the slag drop hopper 11 communicates with the slag feed port through the return pipe 2, and the lower part of the side wall of the casing 8 Finished product discharge port 9 is set. The lower part of the main shaft 4 protrudes out of the rotating body 12 , and the protruding part is provided with a rotating blade 10 . The fixed blade 6 is horizon...

Embodiment 2

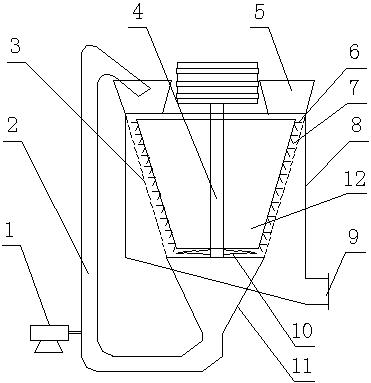

[0020] Such as figure 2 As shown: the difference between this embodiment and the first embodiment is that: the bottom of the casing 8 is a slope structure, the finished product discharge port 9 is set on one side of the bottom of the slope, the lower end of the main shaft 4 is provided with a bearing, and It is connected with the casing 8 through a support rod, and there are multiple finished product outlets 9 .

[0021] In the material pulverizer of the present invention, the material is sent into the pulverizer through the material feeding port, the material is cut and pulverized by the fixed blade and the movable blade on the rotating body, and the finished pulverized material that meets the requirements is filtered to the filter support through the filter support. In the cavity formed by the filter support and the casing, the slag whose crushing degree does not meet the requirements will continue to be crushed along the slope-shaped gap between the filter support and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com