Axle counting system

A technology of axle counting and wheel sensors, which is applied in vehicle route interaction equipment, railway car body components, railway signals and safety, etc., can solve problems such as inability to indicate maintenance personnel, wheel sensors are easily interfered, and complex equipment, etc., to improve railway Operational efficiency and shortened maintenance time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] This embodiment is a preferred implementation mode of the present invention, and other principles and basic structures that are the same or similar to this embodiment are within the protection scope of the present invention.

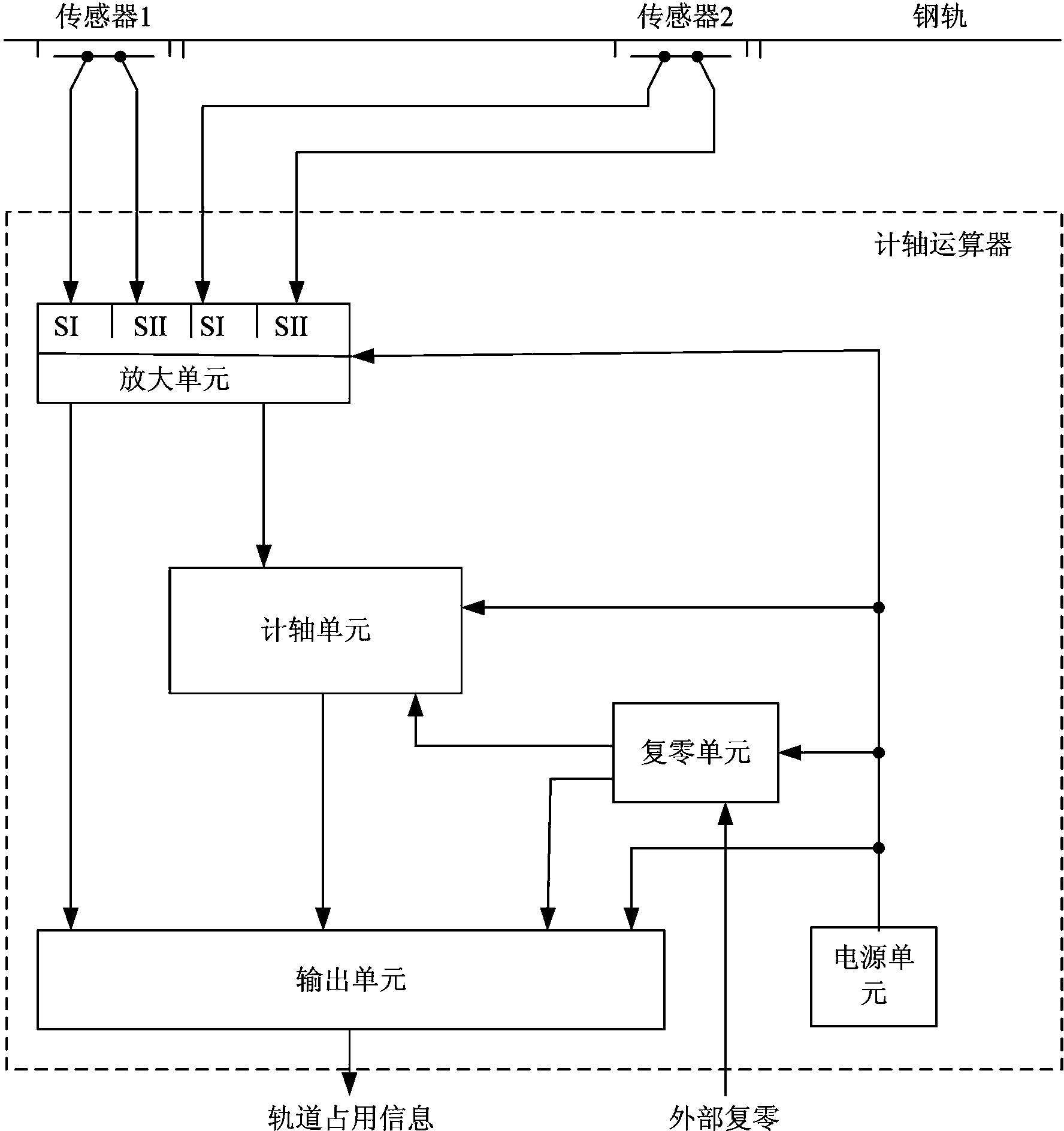

[0021] The axle counting system is used to check whether there is a train on the track. Specifically, the wheel sensor is used as the dividing point to divide the rail into sections. The track area formed between two wheel sensors is called a section. The axle counting system Compare the number of wheels entering the section with the number of wheels leaving the section. When the number of wheels entering is equal to the number of wheels leaving, it is determined that there is no train in the section, that is, the section is idle. When they are equal, it is determined that there is a train in the section, that is, the section is occupied.

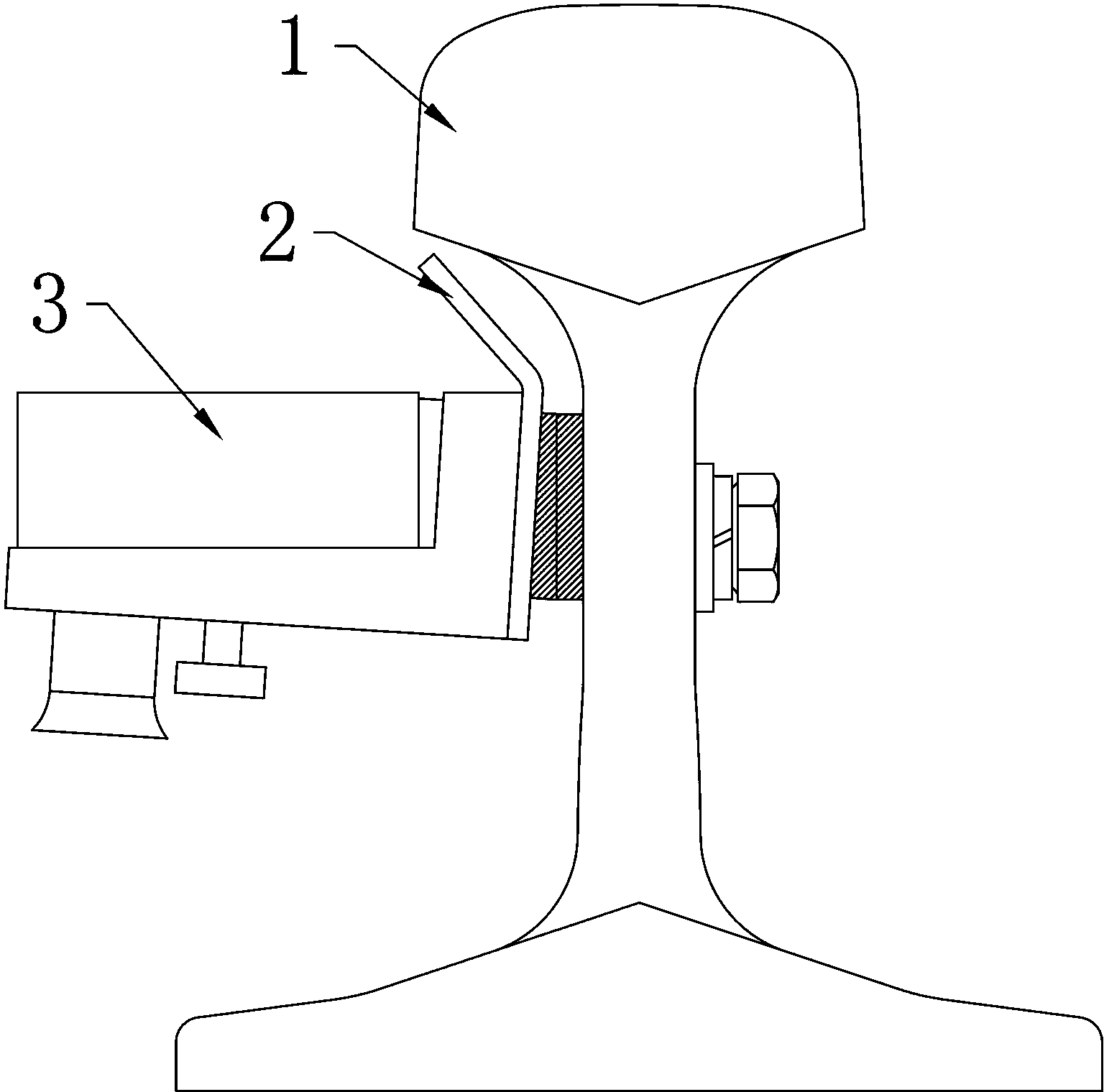

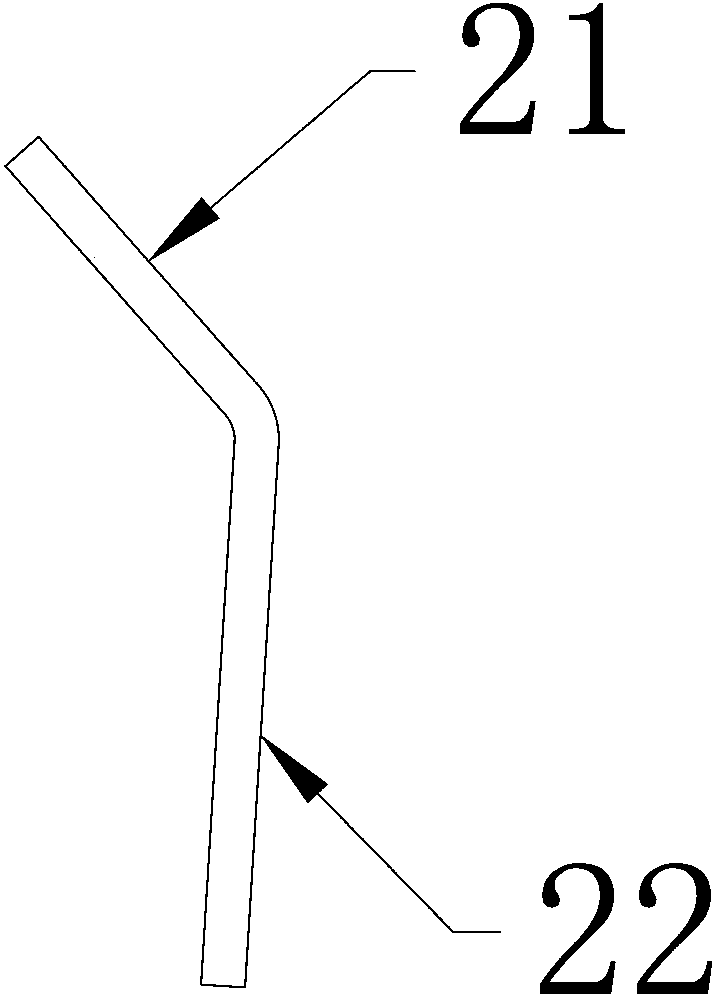

[0022] The axle counting system of this embodiment includes a wheel sensor and an axle counting calculator. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com