A roof fissure water exporting device and method

A technology of roof cracks and exporting devices, which is applied in safety devices, drainage, earthwork drilling and mining, etc., can solve the problems of anchor cables not being able to be laid, poor anchoring strength, collapse and injury, etc., to increase the water guiding effect and service life , easy to construct and ensure reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the embodiment in the accompanying drawings:

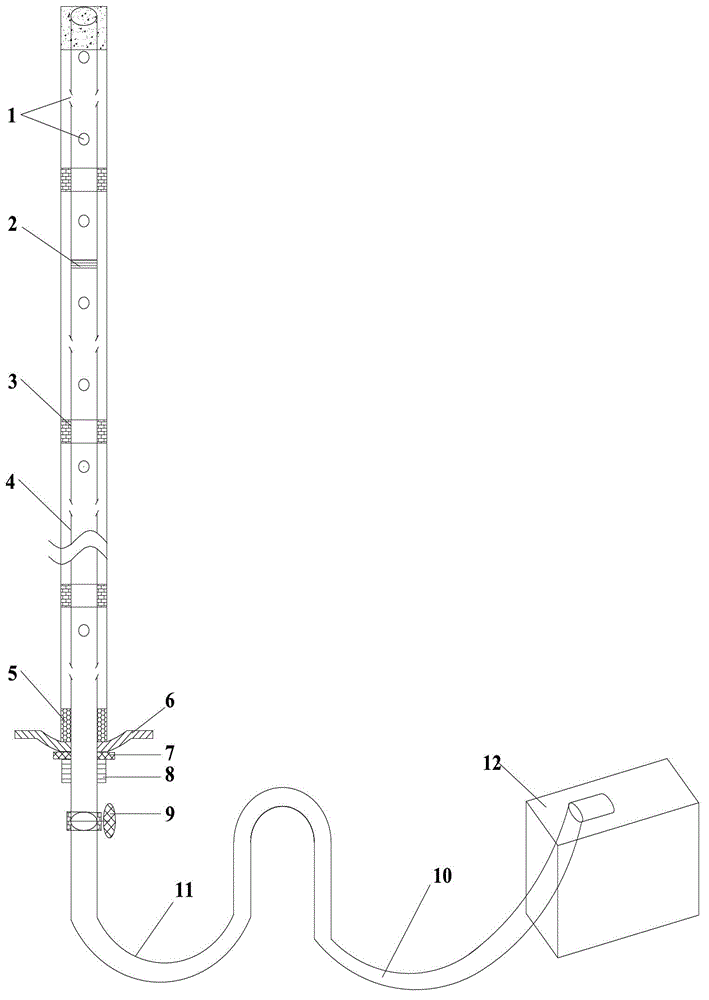

[0021] The roof fissure water exporting device of the present invention comprises an aqueduct 4 extending into the borehole, a tray 6 arranged at the exposed end of the aqueduct 4, a gasket 7, a nut 8, a gate valve 9, and a drainage pipe 10 arranged outside the borehole; The water guide pipe 4 is connected by a plurality of seamless steel pipes through the steel sleeve 2, and a number of water guide holes 1 arranged in a cross shape are drilled at intervals on the water guide pipe 4. The water guide holes 1 are provided with downwardly inclined inner chamfers. The outer wall of the water pipe 4 is provided with water blocking rings 3 at intervals, and the exposed end of the water pipe 4 is connected to the drainage pipe 10 fixed on the roof or the side of the road through the gate valve 9, and a U-shaped pipe 11 is provided on the connecting section be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com