Hydraulic controls with load pressure reduction

A technology of control device and pressure, applied in fluid pressure actuation device, fluid pressure actuation system test, mechanical equipment, etc., can solve the problems of load signal line leakage, reduce power, hinder the full utilization of pump power, etc., to achieve design simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

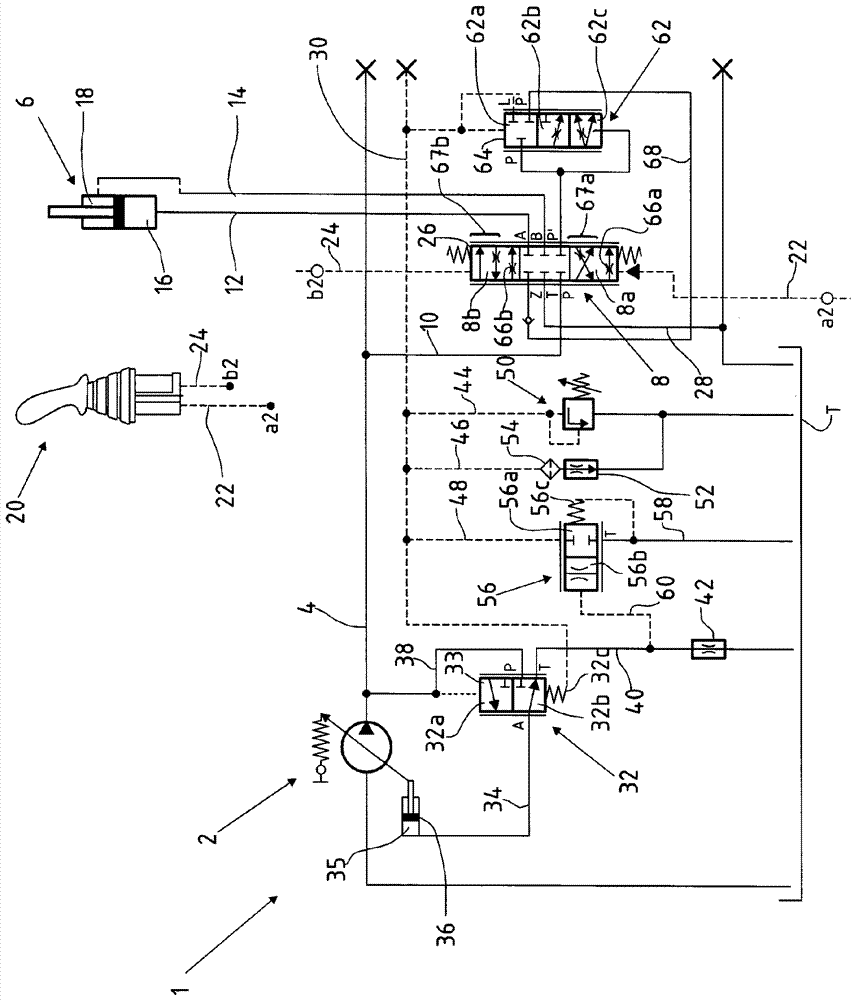

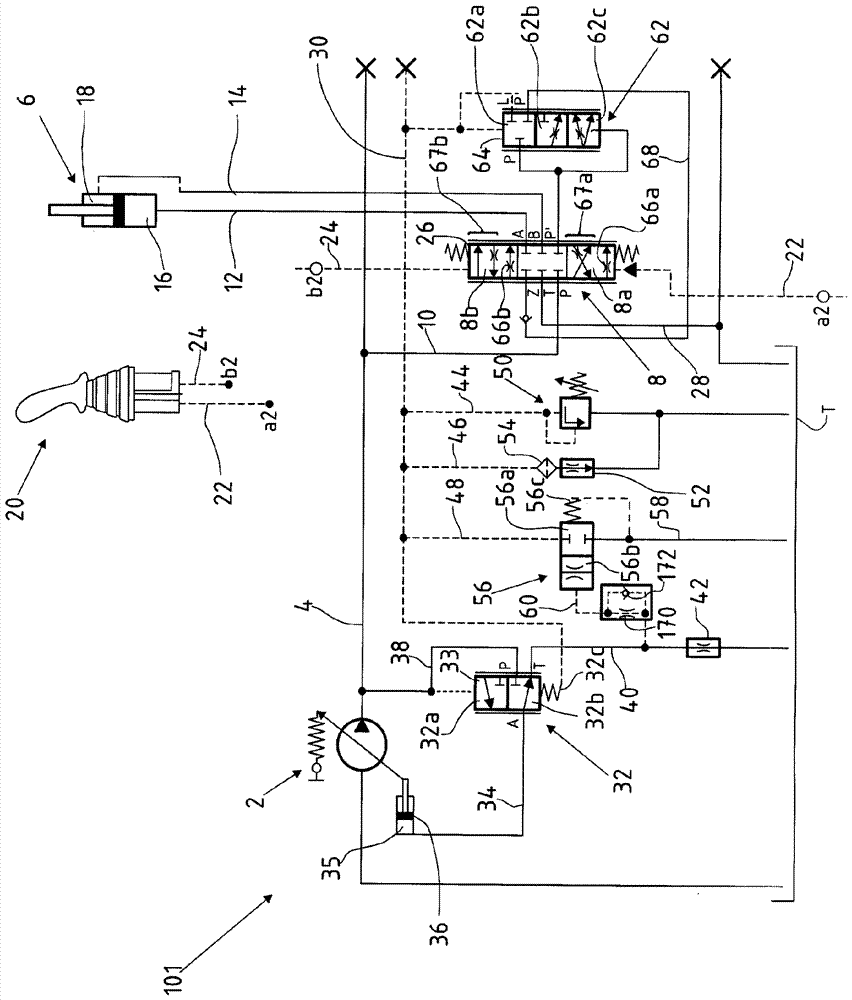

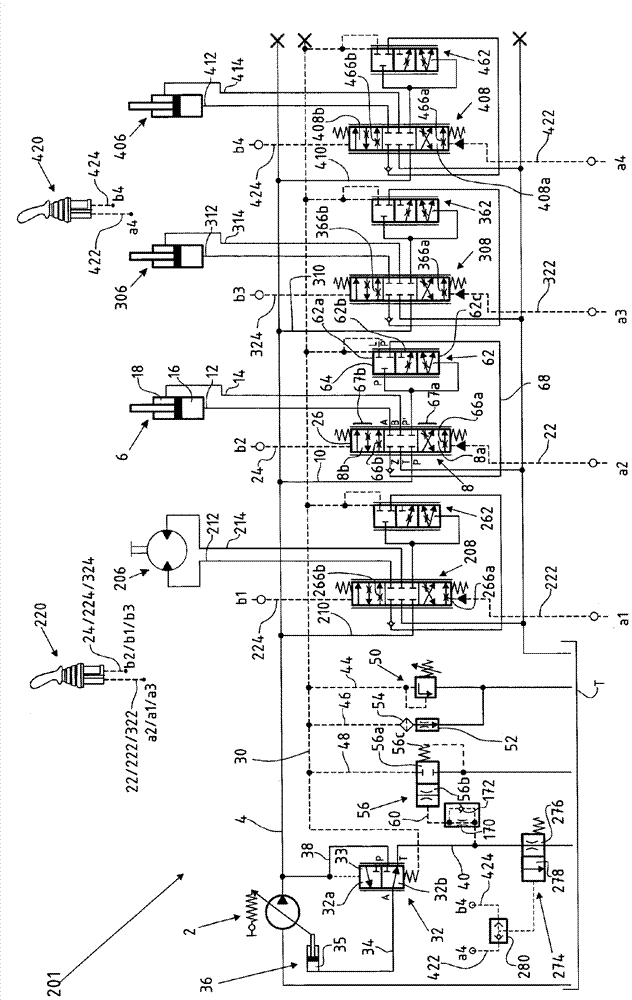

[0084] according to figure 1, the hydraulic control unit 1 of the compact excavator has a hydraulic pump 2 with an adjustable delivery volume. The preparation line 4 through the hydraulic pump 2 can feed several hydraulic consumers (see image 3 ) to provide the pressure medium. according to figure 1 , of these hydraulic consumers only the first hydraulic consumer 6 is shown, which is formed by a synchronized cylinder with a one-sided piston rod for actuating the boom of the micro-excavator. In order to actuate the first hydraulic consumer 6 , a control valve 8 is assigned to said consumer. In this case, the control valve 8 is designed as a 6 / 3 proportional directional valve (6 / 3 proportional directional valve) with a spring-centered blocking position. The control valve 8 is connected via a working line 10 to the auxiliary line 4 of the hydraulic pump 2 and via working lines 12 , 14 to the working chambers 16 , 18 of the first hydraulic consumer 6 . For actuating the cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com