Dual clutch

A dual-clutch, wet-type dual-clutch technology, applied in the direction of clutches, fluid-driven clutches, mechanical-driven clutches, etc., can solve the problems of lack of centrifugal oil chamber and inability to affect cooling oil flow, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

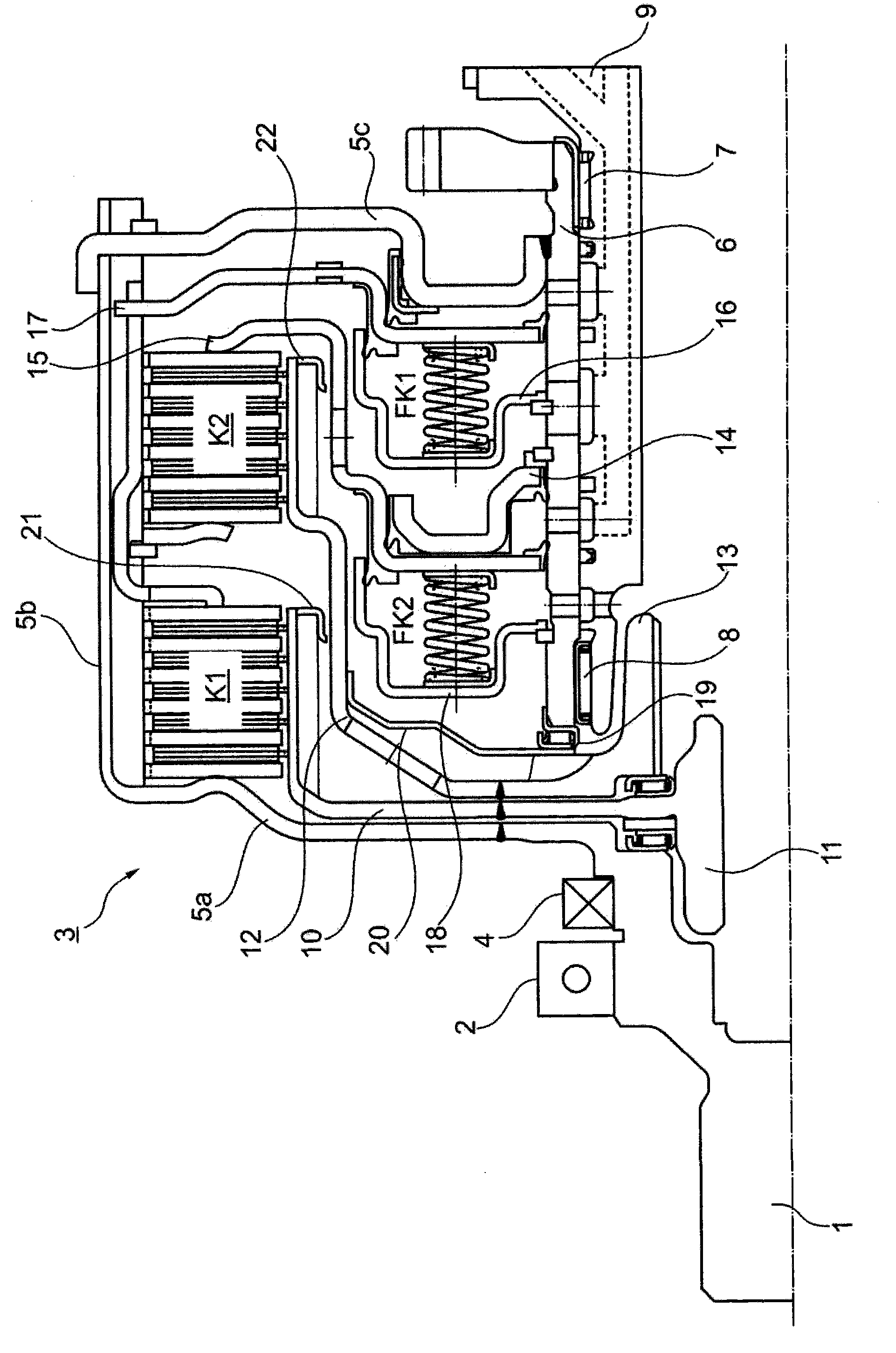

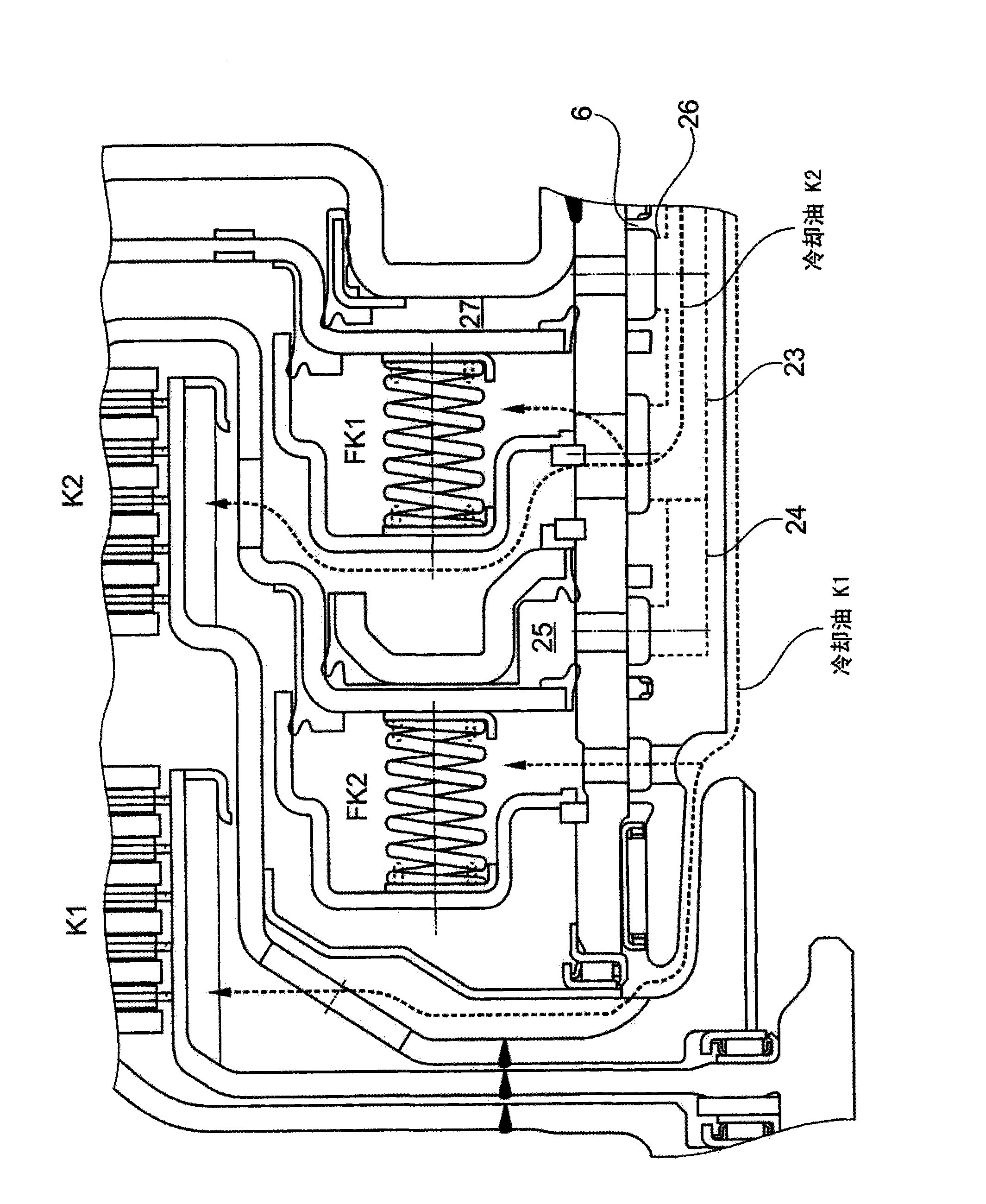

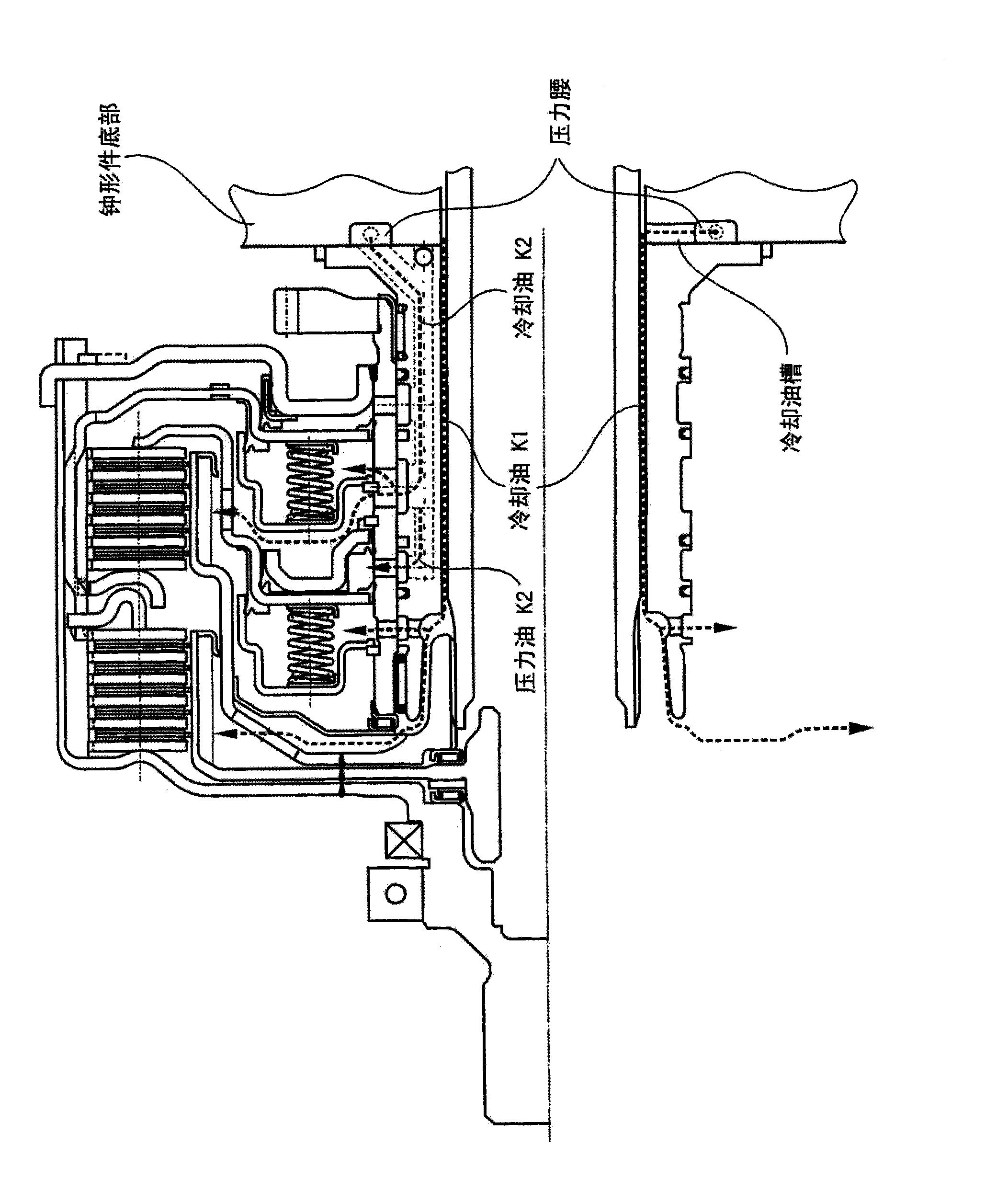

[0014] figure 1 A first exemplary embodiment of an axial wet dual clutch is shown, in which the torque from the drive motor is transmitted to the clutch hub, optionally via a torsional vibration damper, for example a dual mass flywheel (ZMS). The clutch hub 1 is supported on a ( figure 1 (not shown) housing that encloses a clutch bell in which the dual clutch assembly 3 is housed. The clutch bell, which accommodates the clutch 3 , is sealed from the environment by a sealing device 4 . The clutch bell is here generally formed by a recess (not shown separately) in the transmission housing. The clutch hub 1 is connected to a clutch housing 5 comprising a substantially radially extending entrainment region 5a and a substantially axially extending cylindrical region 5b with respect to the main axis of the dual clutch 3 and a radially extending connection - and the support area 5c. The connection and support region 5c is rotationally fixed and preferably also axially fixedly con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com