Production process for gas discharge tube

A production process and technology of electric light tubes, applied in the field of production process of gas discharge light tubes, can solve problems such as unusable light tubes and air leakage at joints, and achieve the effects of high connection stability, good quality, and simple processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

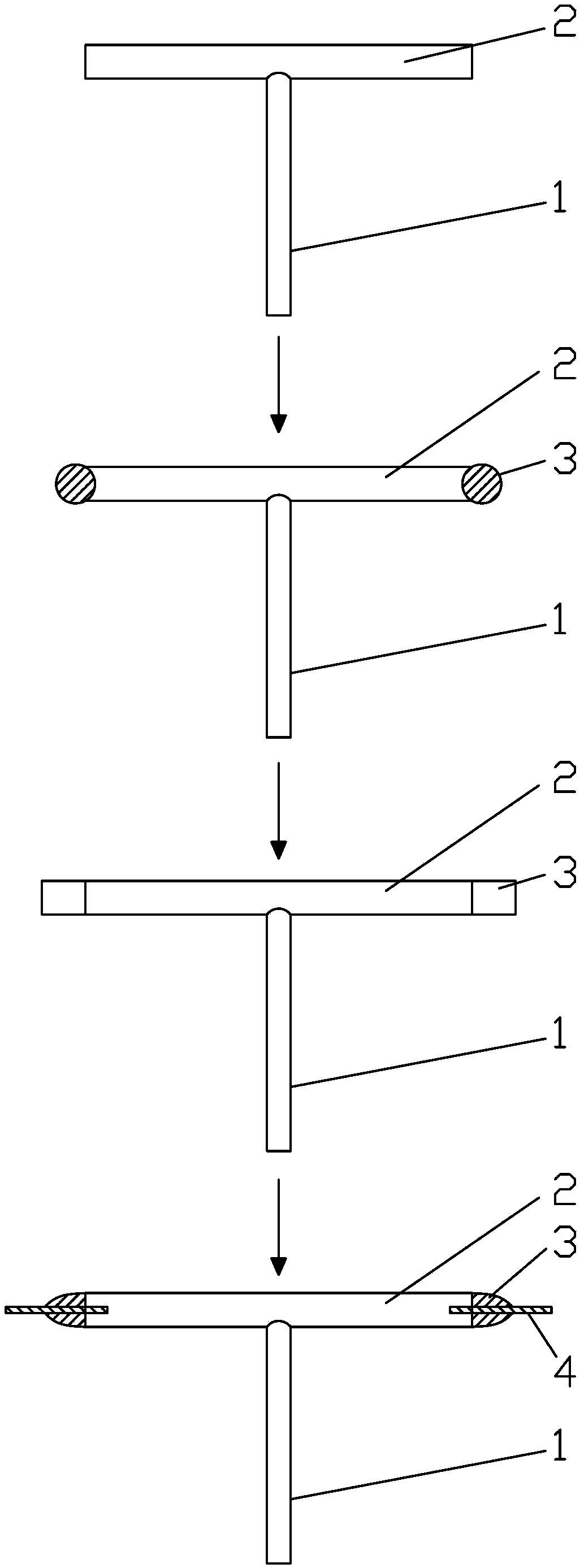

[0018] refer to figure 1 , a kind of gas discharge lamp production process provided by the present invention, it comprises the following steps:

[0019] Step 1, the exhaust pipe 1 is connected to the lamp tube 2, that is, the exhaust pipe 1 is connected to the lamp tube 2 by welding. This connection method belongs to the prior art and will not be repeated here.

[0020] Step 2, melt the solid spherical transition glass 3 on both ends of the lamp tube 2 at the same time, the expansion coefficient of the transition glass 3 is between the expansion coefficient of the electrode 4 and the lamp tube 2, the most optimal is the expansion of the transition glass 3 The coefficient is close to the expansion coefficient of the electrode 4. The so-called close means that the time expansion rate and the space expansion rate of the electrode 4 and the transition glass 3 are similar or the same after being subjected to temperature changes. In this step, the transition glass 3 is softened in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com