Rotation-free beating machine for paddy field

A beater and paddy field technology, which is applied in the direction of tillage machines, agricultural machinery and tools, shovels, etc., can solve the problems of increased labor intensity, low production efficiency, waste, etc., and achieve the goals of reducing labor intensity, convenient production and processing, and improving production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

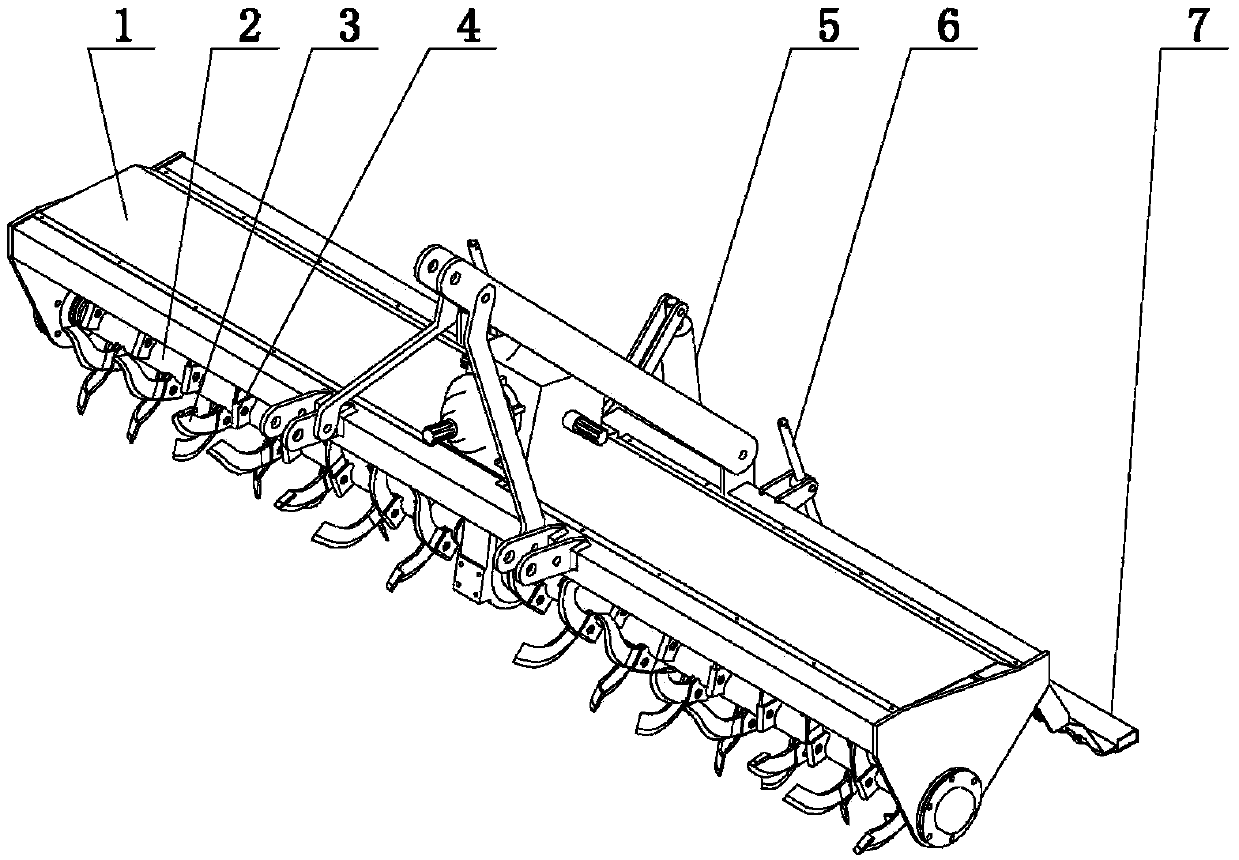

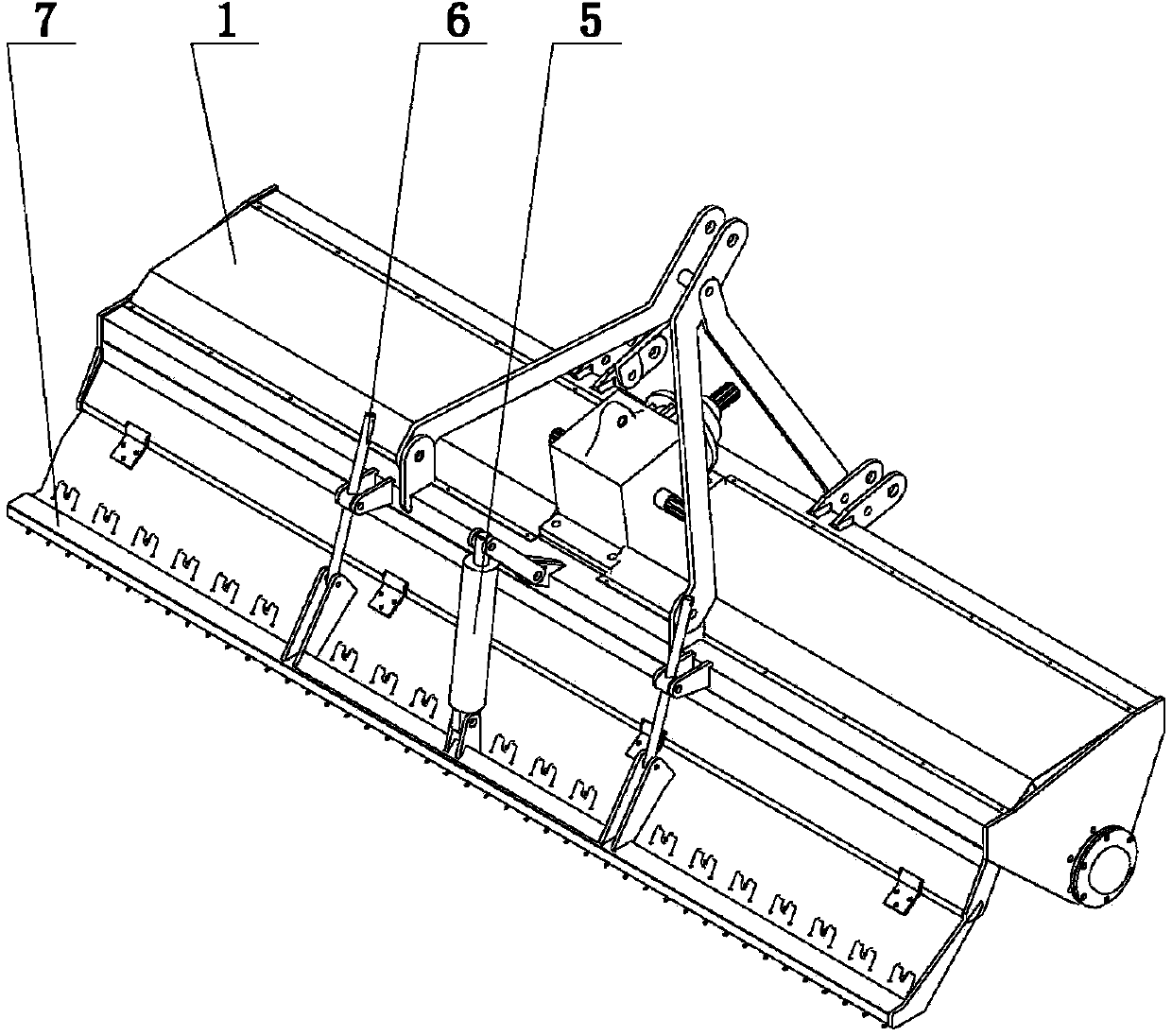

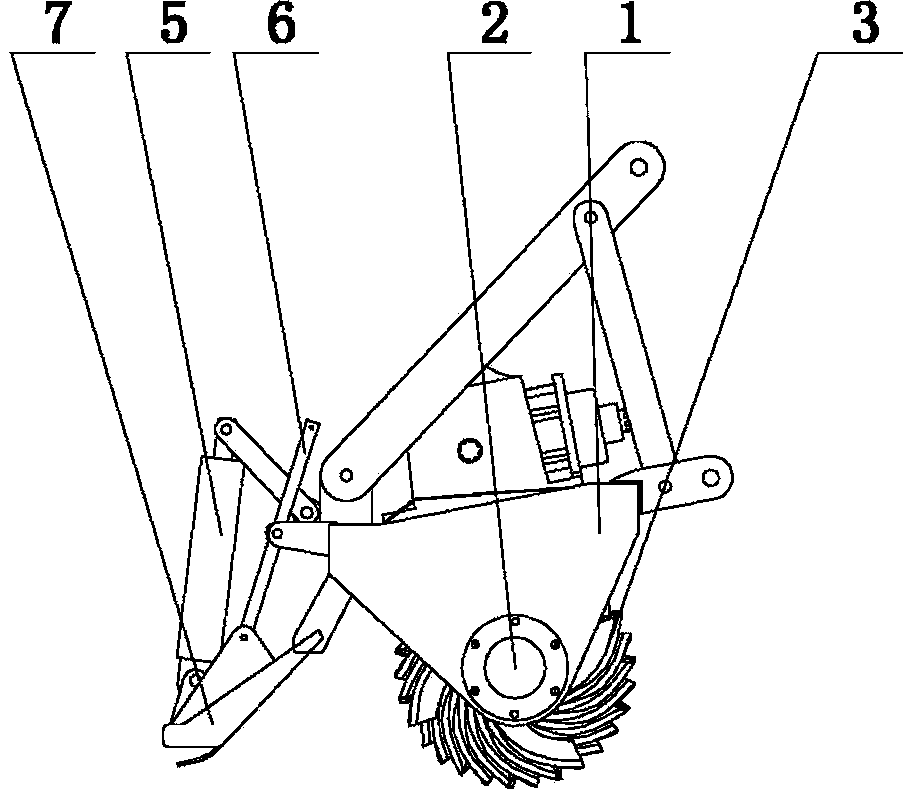

[0022] The present invention comprises a frame 1, on which a main shaft 2 is arranged, and is characterized in that: a pair of relative cutters 3 are arranged at a distance L of 50 to 100 mm on the main shaft 2, and the clamp between two adjacent pairs of cutters 3 Angle α is greater than 90° and less than 100°.

[0023] Preferably, the distance between two pairs of cutters 3 on the spindle 2 is set to 78 mm; the included angle between two adjacent pairs of cutters 3 is 96°. It can be directly beaten without rotary tillage, and the beating effect is good. The beating depth ranges from 80 to 160mm. No particles obviously larger than 10mm.

[0024] As a preferred solution of the present invention, the rear of the frame 1 is hingedly provided with a pressing fork frame 7 with a pressing fork, and a hydraulic cylinder 5 connected to the frame 1 is arranged above the fork frame 7 .

[0025] Further, the pressing forks are arranged equidistantly.

[0026] The main shaft 2 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com