Automatic assembling device of fog lamp dimming ball component

An automatic assembly device and ball head technology, applied in assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of unable to further improve production efficiency, unable to adjust the spring force, complex structure, etc., to shorten the auxiliary operation time, improve the Operational safety, effect of simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

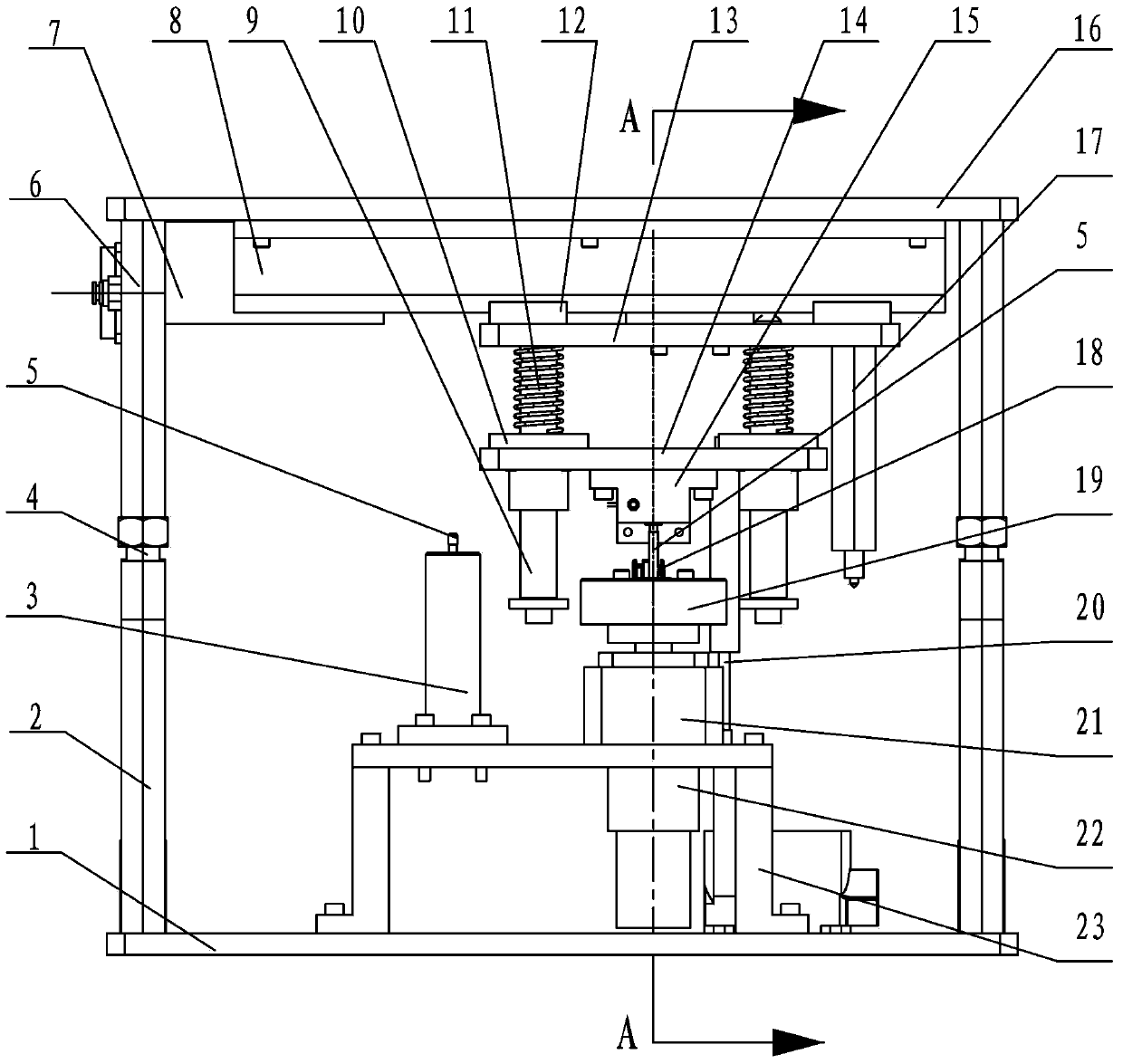

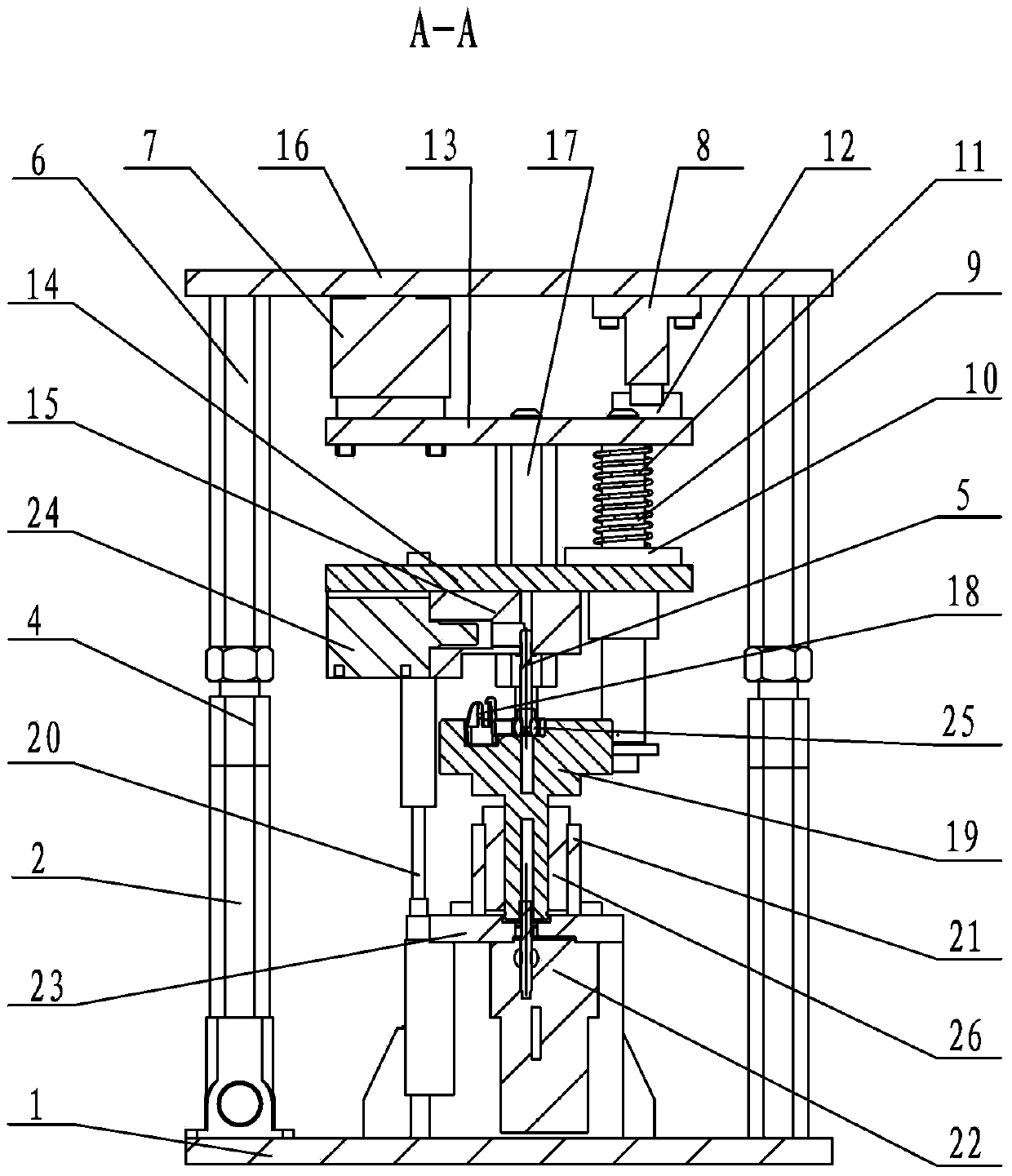

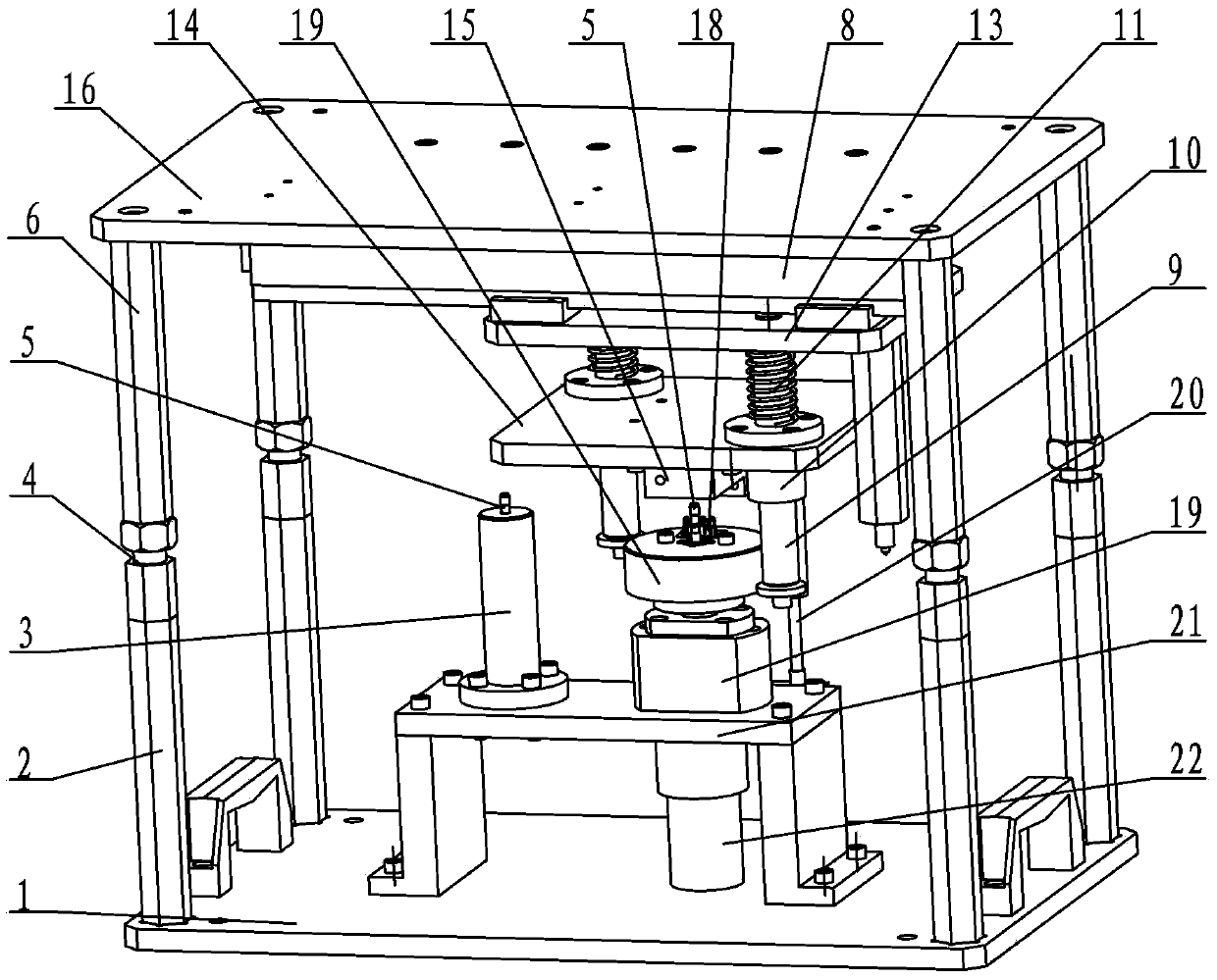

[0014] See Figure 1~3 As shown, the automatic assembly device of the fog lamp dimming ball head assembly of the present invention includes an upper mold assembly capable of moving up and down and a lower mold assembly installed on a workbench.

[0015] See Figure 1~3 As shown, the lower mold assembly of the present invention includes a bottom plate 1, at least four lower limit posts 2 installed on the bottom plate 1, a screw seat 3 installed on the bottom plate 1 through a bracket 23, and a ball head frame positioning and rotating mechanism, and the screw seat 3. Set the dimming screw hole. The bottom plate 1 of the present invention is installed on the workbench of the press through fasteners. The dimming screw 5 can be set in the dimming screw hole of the screw seat 3. light screw 5. See Figure 1~3 As shown, the ball head positioning and rotating mechanism of the present invention includes a motor 22, a support seat 21 and a rotating platform 19, and a bracket 23 is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com