Reinforcing type forging press indexing positioning device

An indexing positioning and upsetting machine technology, applied in the field of forging machinery, can solve the problems affecting the bending and upsetting precision and yield of crankshafts, low production efficiency, and large cumulative errors, etc., and achieve simplified loading and unloading operations, production Convenience, little accumulated error effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

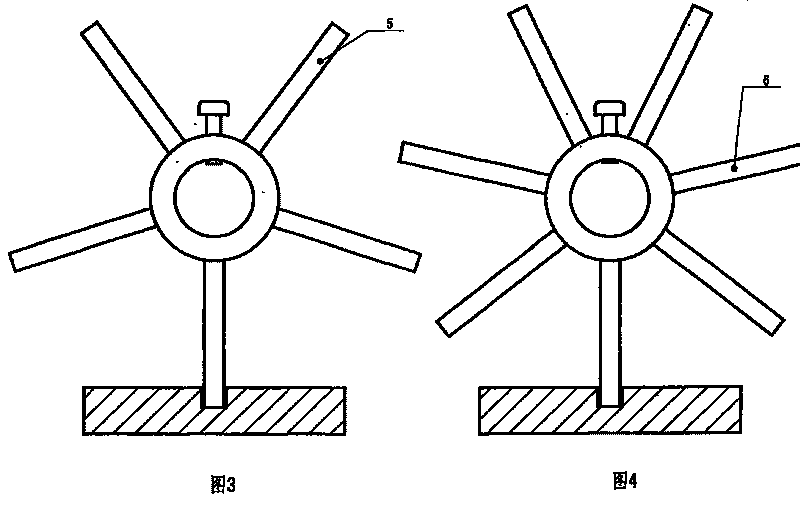

[0020] 1. The indexing and positioning device has a simple structure and is easy to manufacture, and can replace the existing positioning module, which greatly simplifies the overall structure of the mold and saves the cost of the mold.

[0021] 2. The indexing positioning device has higher positioning accuracy than the existing module positioning method, and the accumulated error of multi-step positioning is extremely small, which solves the problem of waste products caused by inaccurate indexing.

[0022] 3. After adopting the indexing positioning device to replace the existing module positioning method, the operation of adjusting the positioning module in each working step is eliminated, and the loading and unloading operations are simplified, the auxiliary operation time is saved, and the productivity is improved.

[0023] The present invention solves its technical problem and realizes by taking the following technical solutions:

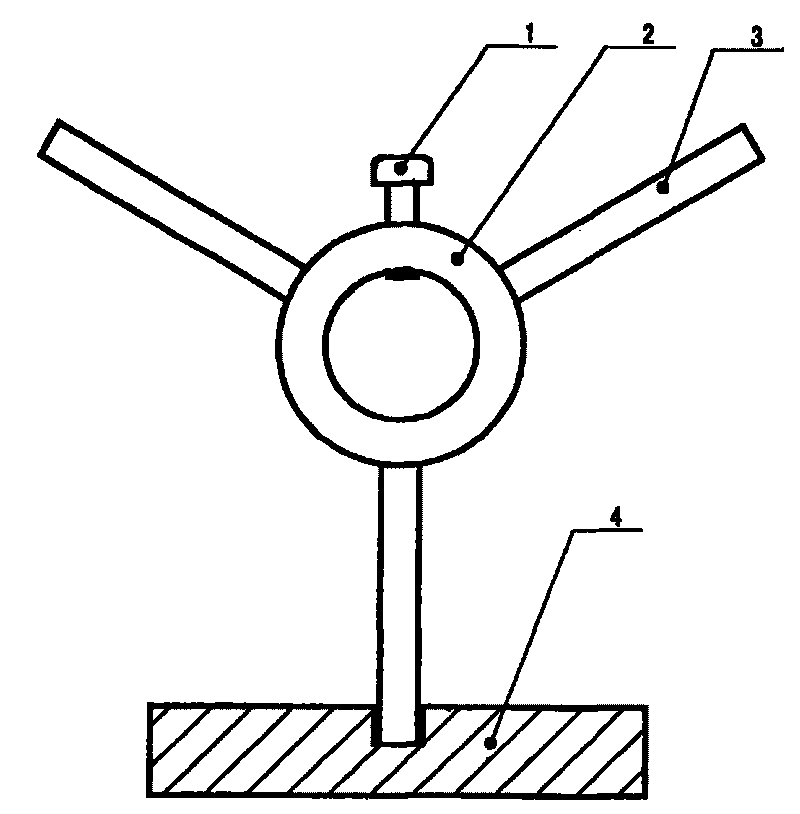

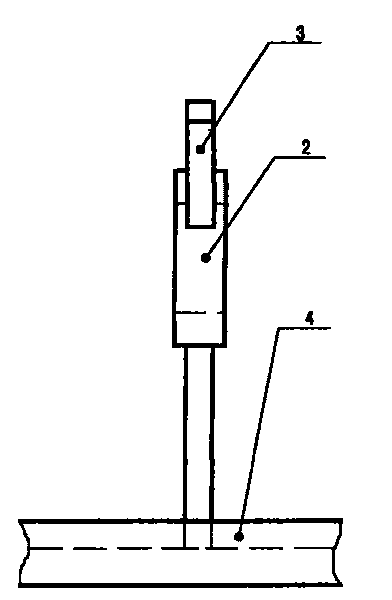

[0024] The billet indexing and positionin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com