Diesel engine and method for increasing power of diesel engine

A diesel engine and engine technology, which is applied in the direction of engine components, engine control, combustion engine, etc., can solve the problem that the power loss cannot be fully compensated, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

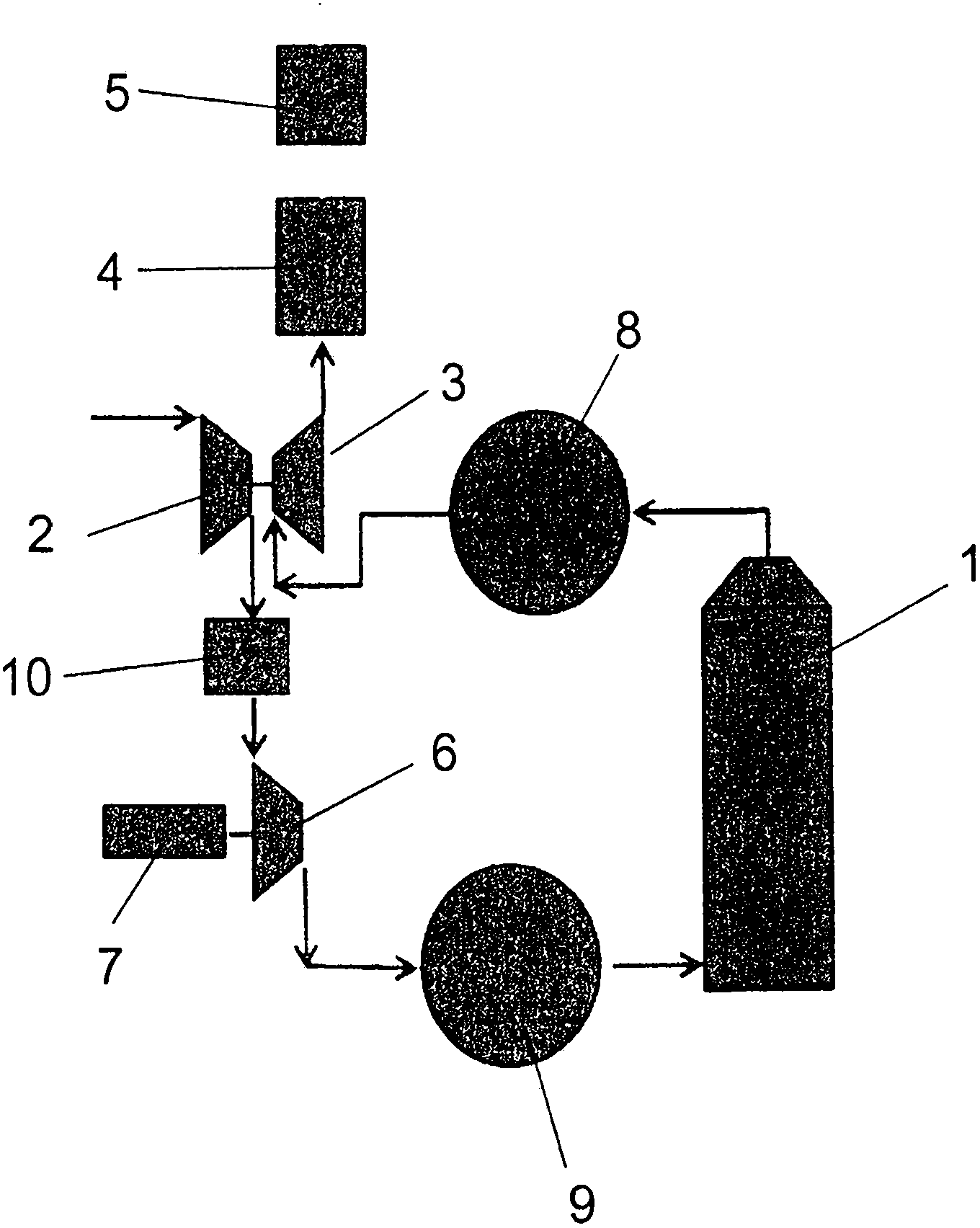

[0026] The reference numeral 1 here designates a combustion chamber of the engine, to which the scavenging gas is fed via a scavenging gas collector 9 at an air intake not shown in detail, and from which exhaust gas passes through which is likewise not shown. The outlet valve shown in detail discharges into the exhaust gas collector 8 . The exhaust gases are fed to the turbine side of the turbocharger stages 2 , 3 . Reference numeral 3 designates a turbine of a turbocharger 2 , 3 , which is shown here only by way of example, and reference numeral 2 designates a compressor of this turbocharger 2 , 3 . Arranged on the low-pressure side of the exhaust gas downstream of the turbine 3 in the direction of flow is an exhaust gas aftertreatment system 4 , 5 which has a steam generator 4 through which the exhaust gas is guided in order to utilize the existing The waste heat in the exhaust gas is used to generate steam. The steam is thus used, for example, in the generator set of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com