An automatic measuring system and method for the winding length of the stacked winding object of the hoist

An automatic metering and winch technology, applied in the direction of instruments, measuring devices, etc., can solve the problems of obtaining the winch, normal production influence, failure to measure the winding length of the winch in real time, etc., and achieve accurate calculation results , the effect of convenient calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

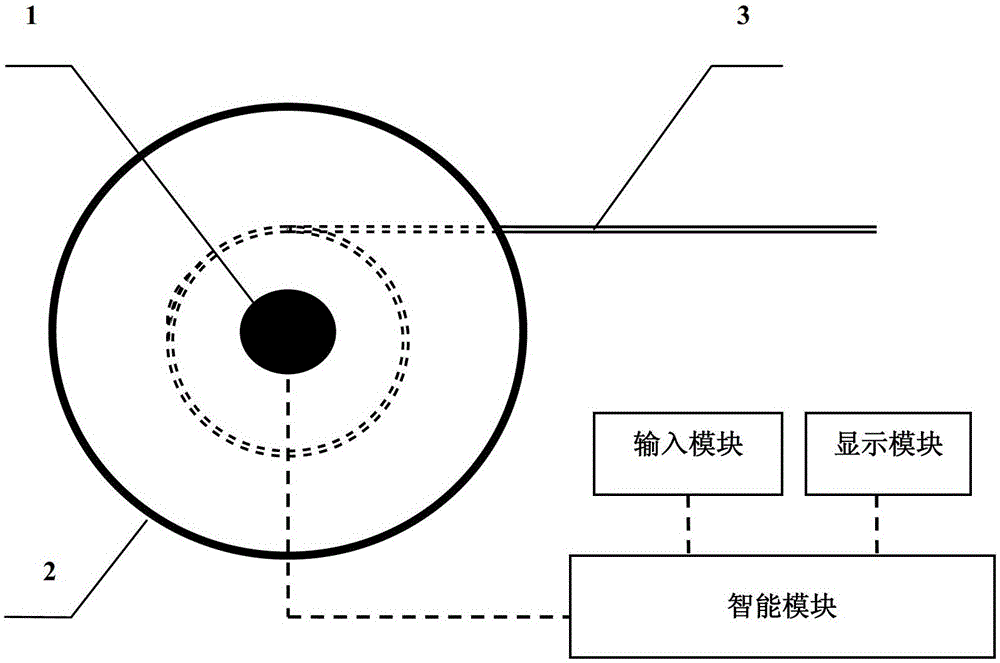

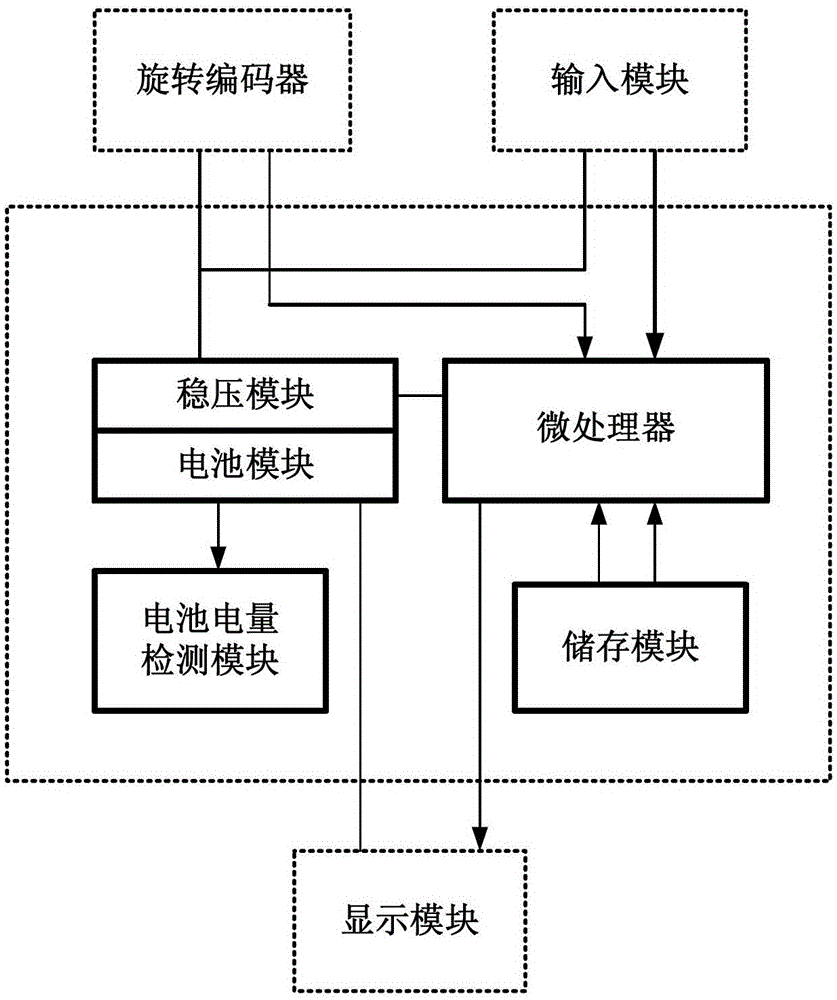

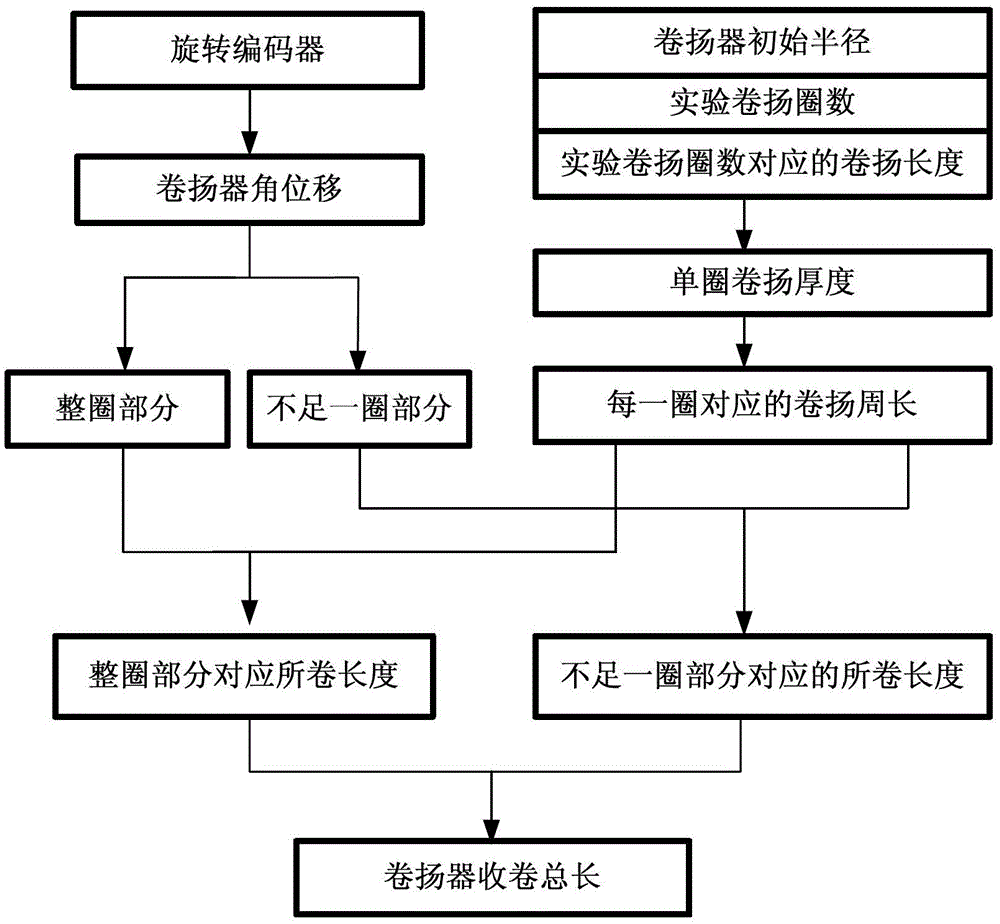

[0057] see figure 1 , the invention of the winding length automatic measuring system of the stacked winding object of the hoist includes a rotary encoder 1, an input module, an intelligent module and a display module.

[0058] The rotary encoder 1 is used to collect the angular displacement θ of the hoist 2 relative to the initial position. The rotary encoder 1 can be a magnetic encoder or a photoelectric encoder, and is connected to the shaft of the hoist 2 through a flange or a coupling, or a motor with a built-in encoder can be selected to drive the hoist 2 . In order to meet the function of measuring the number of turns, an incremental encoder or a multi-turn absolute encoder is required.

[0059] The input module includes an input keyboard through which relevant parameters are pre-input to the system, and these parameters include the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com