Online grain moisture content detection system and method based on temperature and humidity inversion

A detection system, temperature and humidity technology, applied in the direction of testing food, measuring devices, material inspection products, etc., can solve the problems of high cost, complex structure, unable to be densely arranged, etc., and achieve high reliability, easy operation, and reduced labor costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

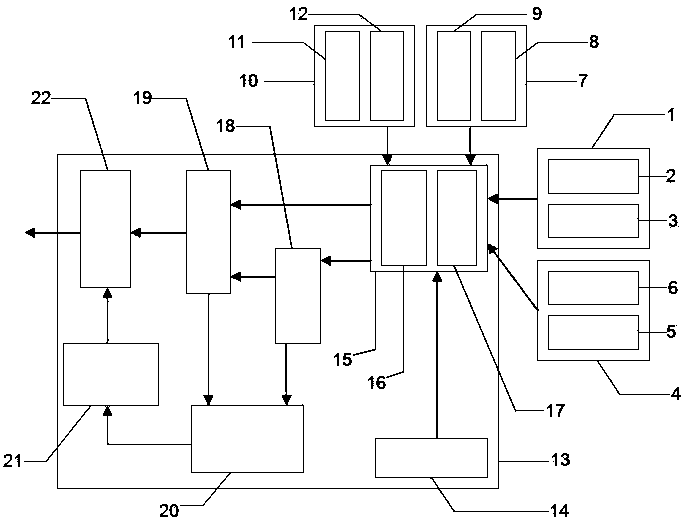

[0024] As attached figure 1 As shown, taking four temperature and humidity detection units as an example, No. 1 temperature and humidity detection unit 1 includes No. 1 temperature detection unit 2 and No. 1 humidity detection unit 3, No. 1 temperature detection unit 2 is responsible for collecting temperature numbers at No. 1 point Or analog signal, No. 1 humidity detection unit 3 is responsible for collecting the humidity digital or analog signal at No. 1 point; No. 2 temperature and humidity detection unit 4 includes No. 2 temperature detection unit 5 and No. 2 humidity detection unit 6, No. 2 temperature detection unit 5 Responsible for collecting the temperature digital or analog signal of No. 2 point, No. 2 humidity detection unit 6 is responsible for collecting the humidity digital or analog signal of No. 2 point; No. 3 temperature and humidity detection unit 7 includes No. 3 temperature detection unit 8 and No. 3 Humidity detection unit 9, No. 3 temperature detection uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com