Ceramic pressure measuring cell

A technology for measuring units and pressure, which is applied in measuring devices, measuring fluid pressure, measuring fluid pressure through electromagnetic components, etc., and can solve problems such as inability to manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

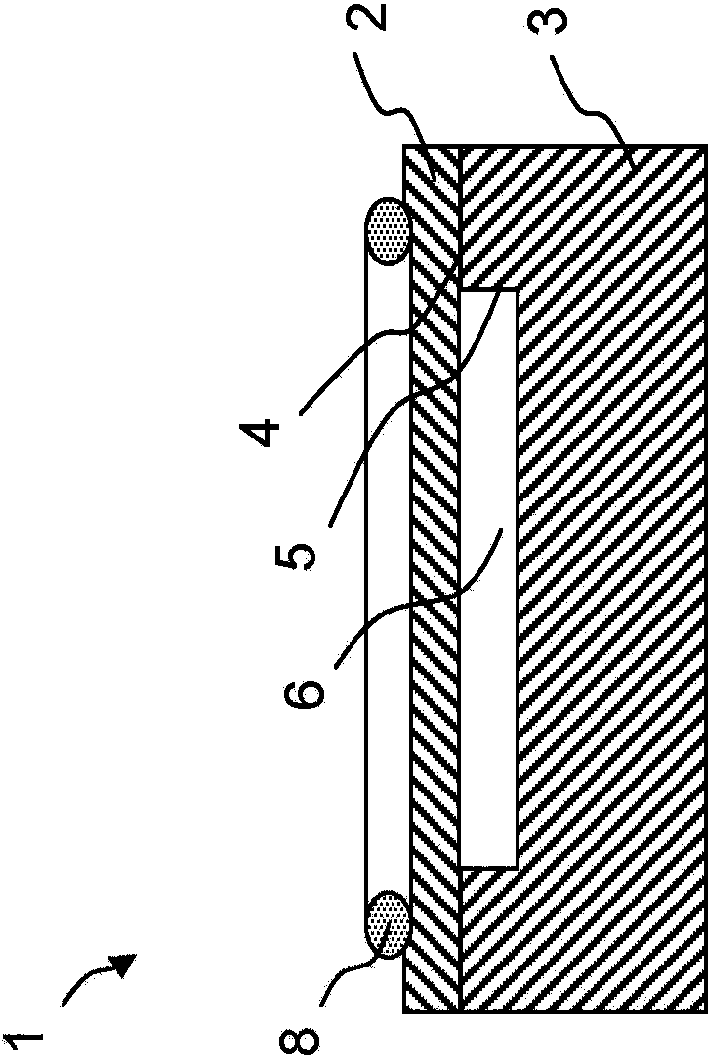

[0029] figure 1 The pressure measuring cell 1 shown in includes a measuring membrane 2 and a platform 3 , wherein the measuring membrane is pressure-tightly connected to the platform along a laser-welded peripheral joint. The measuring membrane 2 has a substantially circular, plate-like shape with a diameter of, for example, 1 cm to 6 cm, and a material thickness of not less than 50 μm and not more than, for example, 2500 μm. The platform 3 here has the same diameter as the measuring membrane 2 , the material thickness of which amounts to a few millimeters to several centimeters. Preferably, the platform is dimensioned such that it undergoes at most negligible deformation under the pressure load of the measuring membrane 2 . On the side of the measuring membrane at the end face of the platform 3, a cavity 5 is formed in order to form a pressure chamber 6 between the measuring membrane 2 and the platform 3, in which the measuring reference pressure is regularized, according to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com