Fiber brag grating dynamic high-pressure transducer

A technology of high pressure sensor and optical fiber grating, which is applied in the direction of fluid pressure measurement using optical methods, can solve the problems of pressure measurement that is not suitable for high frequency response and low pressure sensitivity, and achieves convenient and fast production, strong anti-interference ability, and structural simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

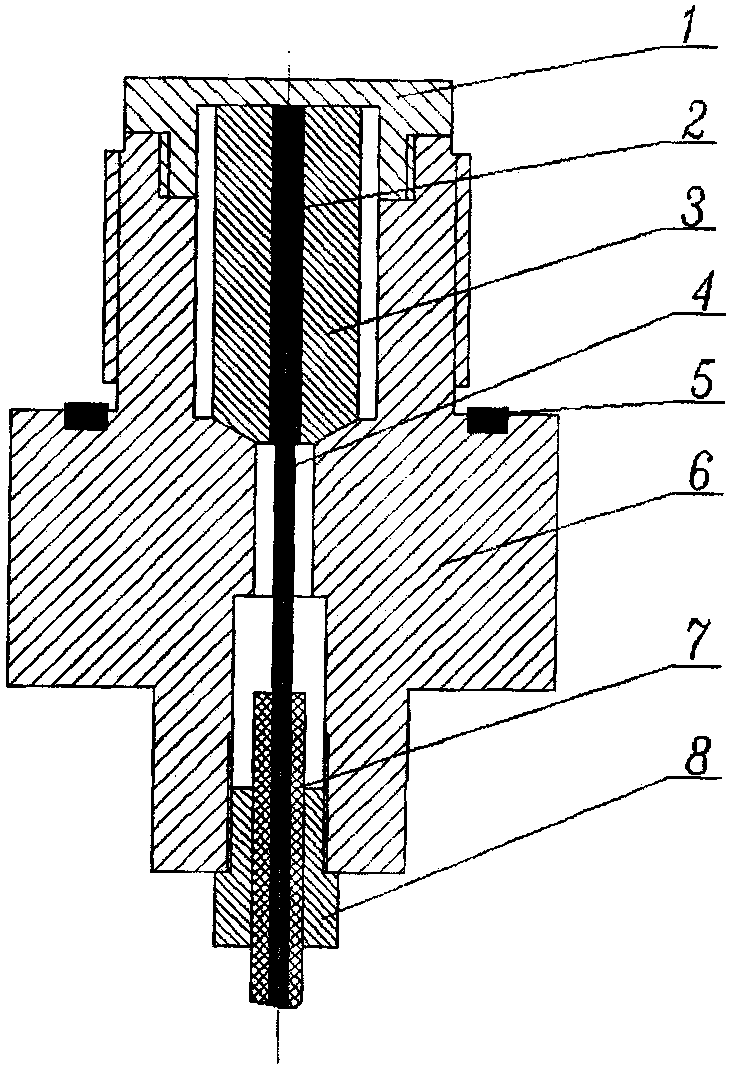

[0016] see figure 1 , The present invention consists of a diaphragm body 1, a filling glue 2, a support column 3, an optical fiber 4 containing a grating (FBG), a sealing gasket 5, an installation shell 6, an optical fiber sheath 7, and a fixed joint 8. The diaphragm body 1 and the front end of the installation housing 6 are fixed to form the pressure-sensitive surface of the sensor. The grating (FBG) on the optical fiber 4 is pasted on the surface of the inner hole of the supporting column 3 in parallel with the axial direction and filled with filling glue 2 in the hole. The upper end surface of the supporting column 3 is in close contact with the diaphragm body 1, the lower end surface of the supporting column 3 and the installation shell 6 adopt a conical contact surface, and the optical fiber 4 inserted into the optical fiber sheath 7 is fixed to the installation shell through a fixed joint 8 At the lower end of the body 6, the sealing gasket 5 is placed in the groove on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com