Lithium battery soft packaging membrane

A technology for flexible packaging films and lithium batteries, which is applied to battery pack components, circuits, electrical components, etc. It can solve problems such as pinholes and cracks in the anti-corrosion treatment layer, which affect the application of packaging films, and achieve good water and oxygen resistance. Effects of tensile and impact resistance, enhanced impact resistance and thermal shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

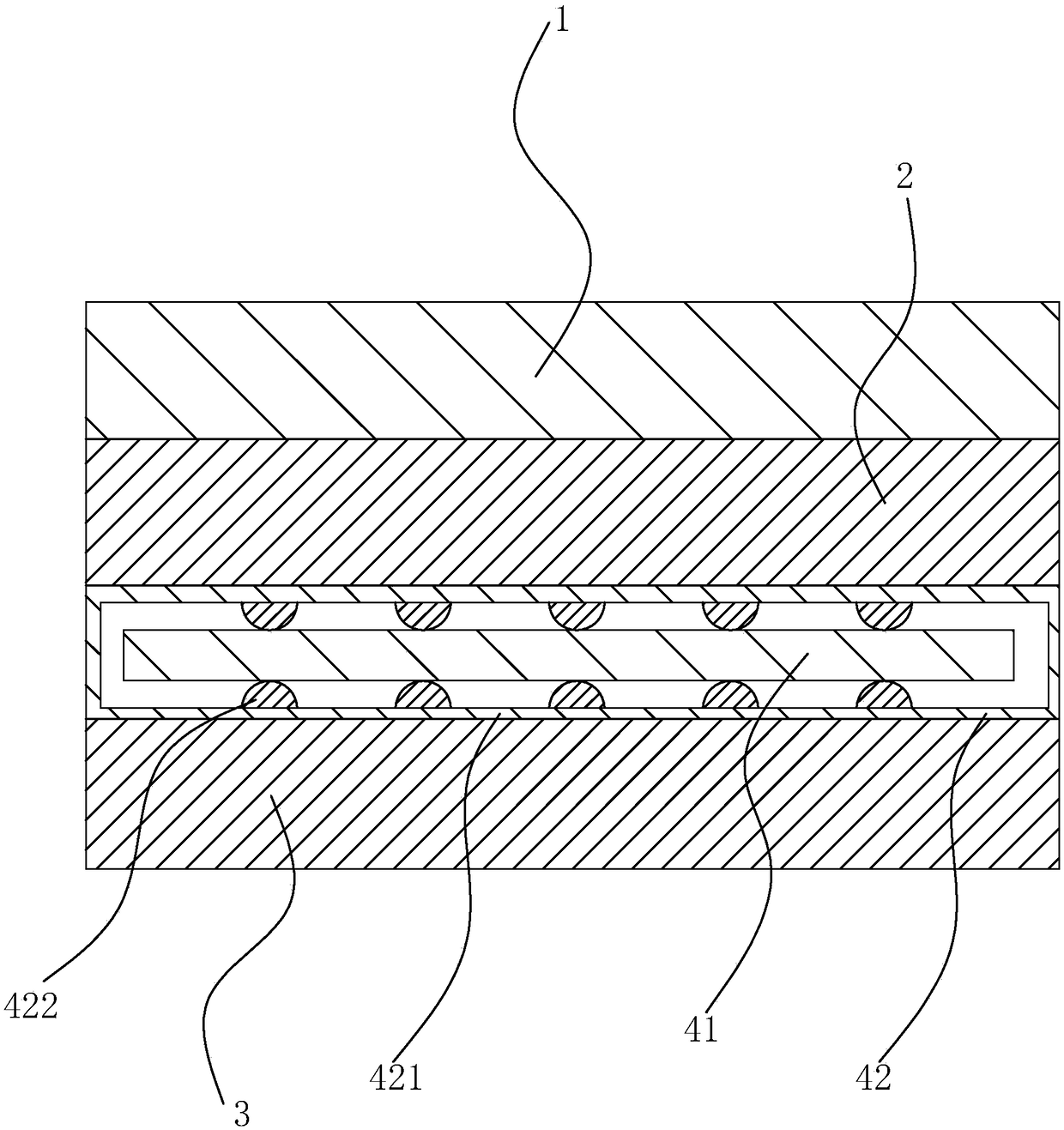

[0039] A lithium battery flexible packaging film, such as figure 1 As shown, it includes a nylon layer 1, an aluminum foil layer 2, and a heat-sealing layer 3 in sequence, wherein an anti-corrosion layer 4 is arranged between the aluminum foil layer 2 and the heat-sealing layer 3; The composite layer 42 on the main membrane body 41 of the anticorrosion layer, wherein the main membrane body 41 is a gel with good corrosion resistance, the composite layer 42 is a non-woven fabric 421 and elastic protrusions 422 arranged on the non-woven fabric 421, The elastic protrusion 422 is disposed toward the main membrane body 41 of the anticorrosion layer.

[0040] The elastic protrusion 422 is made of foamed plastic, and then bonded to the surface of the non-woven fabric layer 421 by heat and pressure.

[0041] The main components of the anti-corrosion layer main film body 41 are organic silane, silica gel, silicone grease, calcium carbonate powder or calcium chloride powder, solvent and...

Embodiment 6

[0053] Step 1: Pour silicone grease, organosilane, silicone grease, and solvent into the reaction vessel and stir at high speed until dissolved;

[0054] Step 2: Add vanadic acid-vanadate solution therein, continue stirring at high speed for 12 hours, and raise the temperature to 65°C;

[0055] Step 3: adding magnesium sulfate hydrate or magnesium oxide thereto, filtering out precipitates and insolubles;

[0056] Step 4: Add calcium carbonate powder or calcium chloride powder, anti-corrosion agent, and the mixture in step 3 to the emulsifier and mix;

[0057] Step 5: Apply the mixture prepared in Step 3 on the surface of the non-woven fabric layer, and raise the ambient temperature to 82°C.

Embodiment 7

[0059] Step 1: Pour silicone grease, organosilane, silicone grease, and solvent into the reaction vessel and stir at high speed until dissolved;

[0060] Step 2: add vanadic acid-vanadate solution therein, continue stirring at high speed for 8 hours, and raise the temperature to 56°C;

[0061] Step 3: adding magnesium sulfate hydrate or magnesium oxide thereto, filtering out precipitates and insolubles;

[0062] Step 4: Add calcium carbonate powder or calcium chloride powder, anti-corrosion agent, and the mixture in step 3 to the emulsifier and mix;

[0063] Step 5: Apply the mixture prepared in Step 3 on the surface of the non-woven fabric layer, and raise the ambient temperature to 78°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com