Method and device for warming a traction battery of a vehicle

A vehicle and battery technology, applied to heating/cooling equipment, secondary batteries, circuits, etc., to achieve the effect of saving cost and structural space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

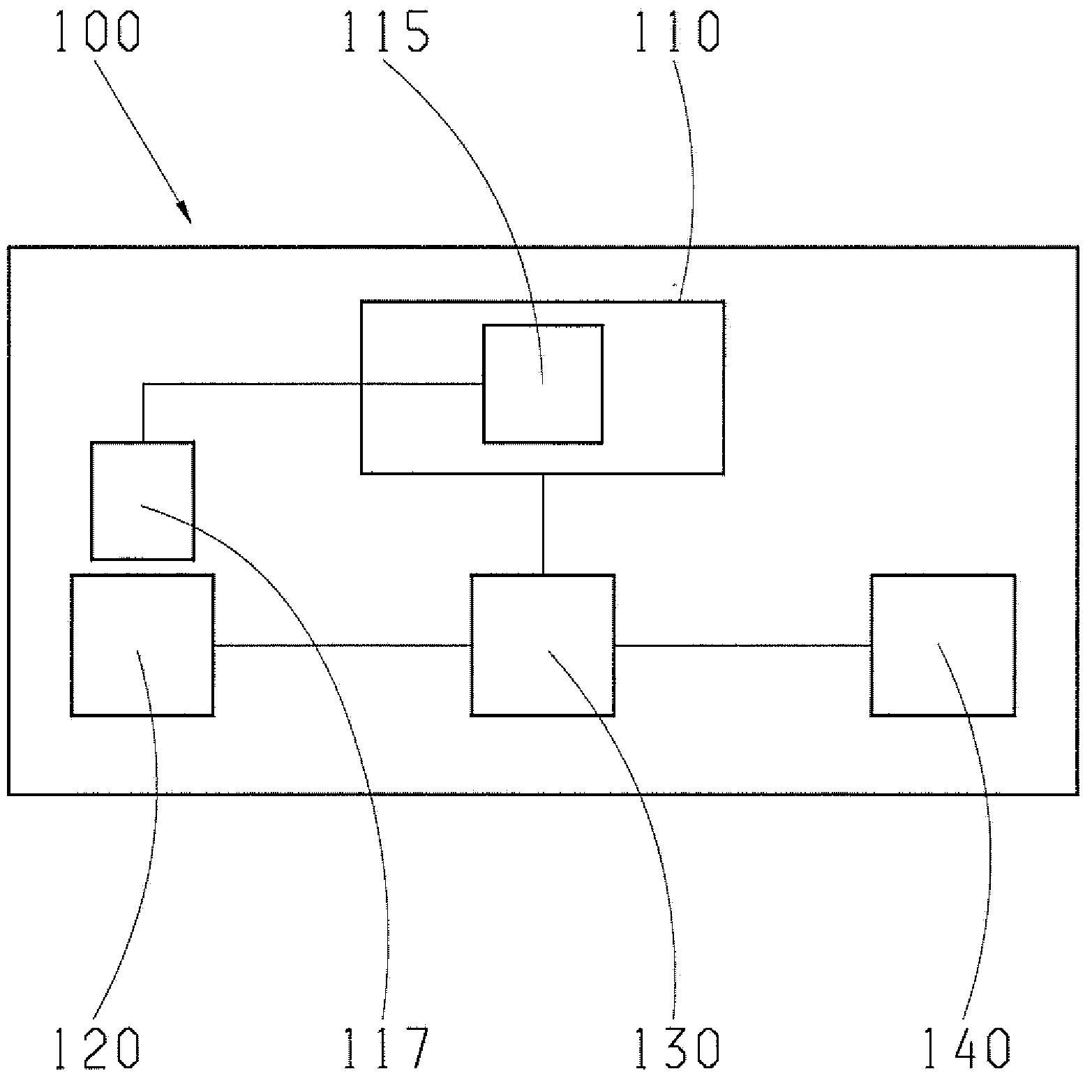

[0034] figure 1 A vehicle 100 is schematically shown with a device 110 for heating a traction battery according to an embodiment of the invention. A device 110 , an adjustment device 115 , a traction battery 120 , an inverter 130 and an electric machine 140 are arranged in the vehicle 100 . The device 110 has an adjustment device 115 .

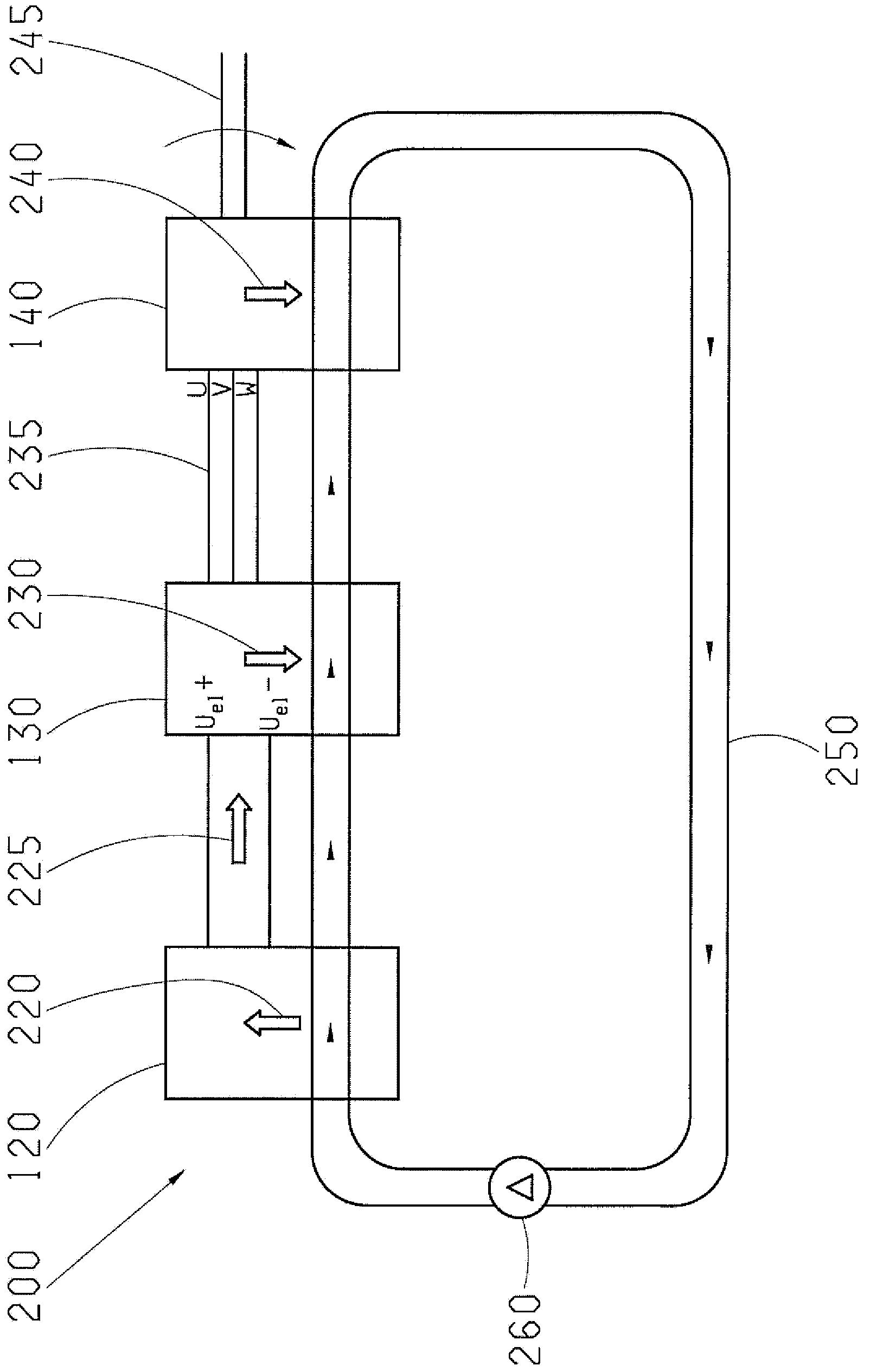

[0035] The inverter 130 is connected to the device 110 , the traction battery 120 and the electric machine 140 via electric lines. As next with the help of figure 2 As described, traction battery 120 and inverter 130 and optionally also electric machine 140 are thermally coupled via a cooling circuit. Electric machine 140 receives an alternating current from inverter 130 , which is generated by means of inverter 130 from a direct current received by traction battery 120 .

[0036] Regulation device 115 is designed to regulate the reactive current portion of the alternating current in order to generate more heat loss in inverter 130 and op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com