High-efficiency air-exchanging and temperature-lowering shed

A shed and air temperature technology, which is applied in poultry cages or houses, application, poultry industry, etc., can solve the problems that the ventilation suppression of chicken houses has not been effectively solved, the cooling effect of chicken houses is discounted, and the loss of producers has been reduced, so as to reduce production The effect of operating cost, less cumbersome structure and high ventilation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in combination with specific embodiments.

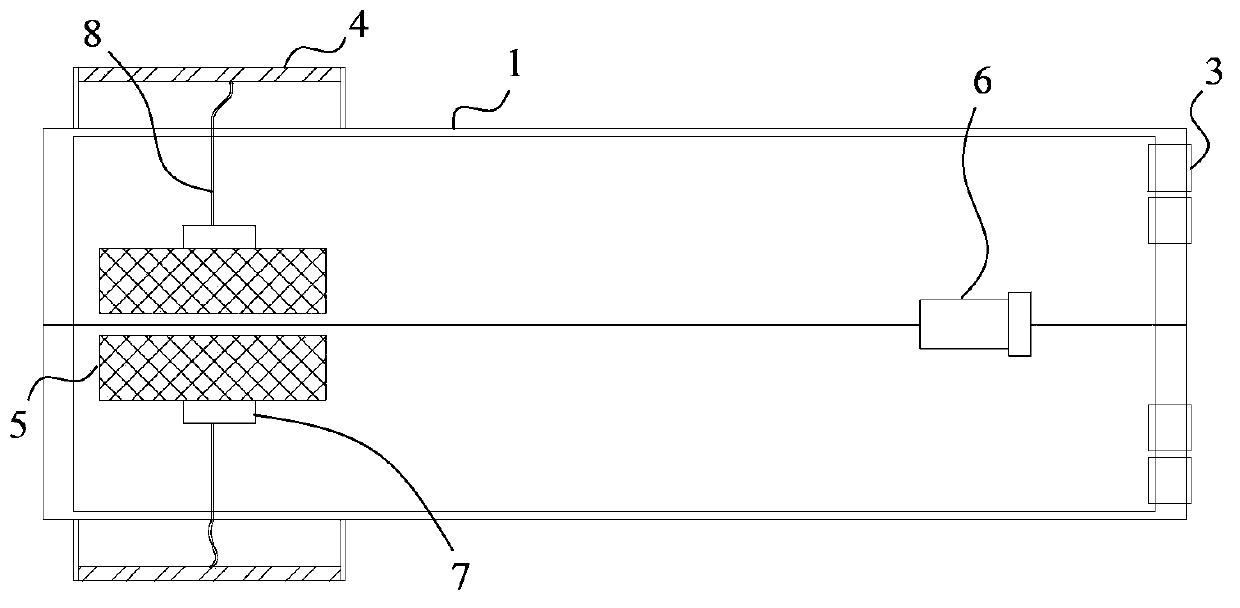

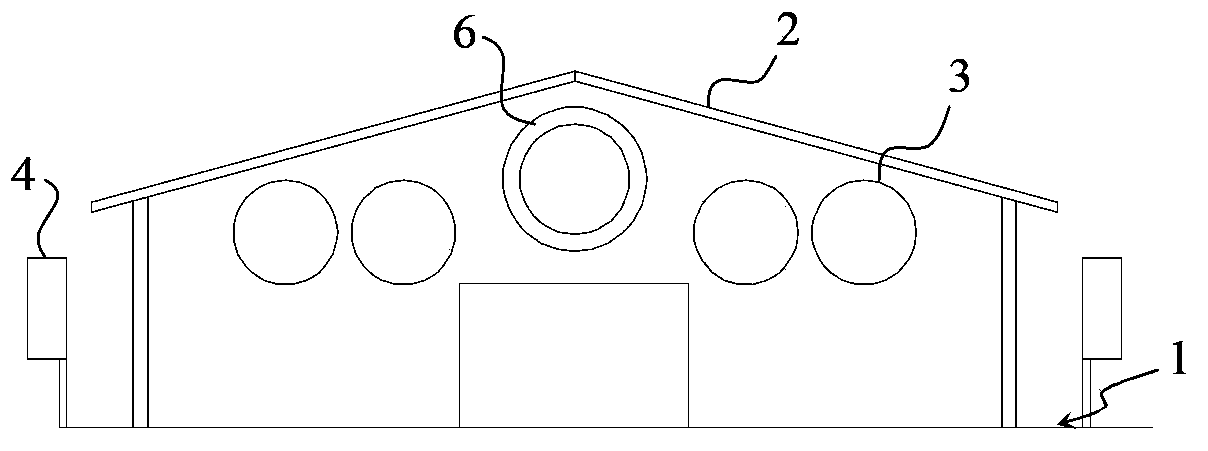

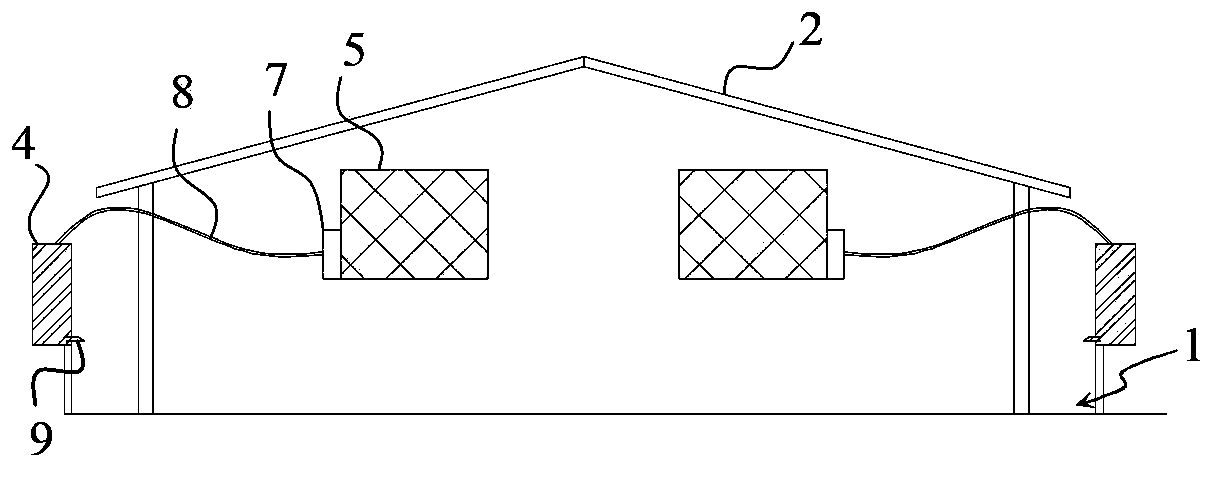

[0014] Please refer to figure 1 , figure 2 , image 3 As shown, a high-efficiency exchange and temperature reduction shed of the present invention includes a wall 1 set up on four sides and with windows on both sides. The long axis of the shed corresponds to the air inlet end and the air exhaust end respectively. The shed also includes a ceiling 2. The fan 3 is installed at the air exhaust end of the wall 1, the outdoor wet curtain device 4 is installed on both side walls of the wall body 1 near the air inlet end, and the indoor wet curtain device 5 is installed under the ceiling 2 near the air inlet end.

[0015] An auxiliary fan 6 is provided below the ceiling 2 of the shed near the exhaust end of the long axis. The auxiliary fan 6 corresponds to the long axis in parallel, and cooperates with the fan 3 at the exhaust end to form a full range of negative pressure. And...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com