Ultrathin low-frequency ventilation acoustic sound absorption unit and sound absorber

A sound absorber and sound absorption technology, applied in the field of acoustics, can solve problems such as difficult structural parameter design, complex structure of ventilation and sound absorbers, and large space outside the pipeline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the examples.

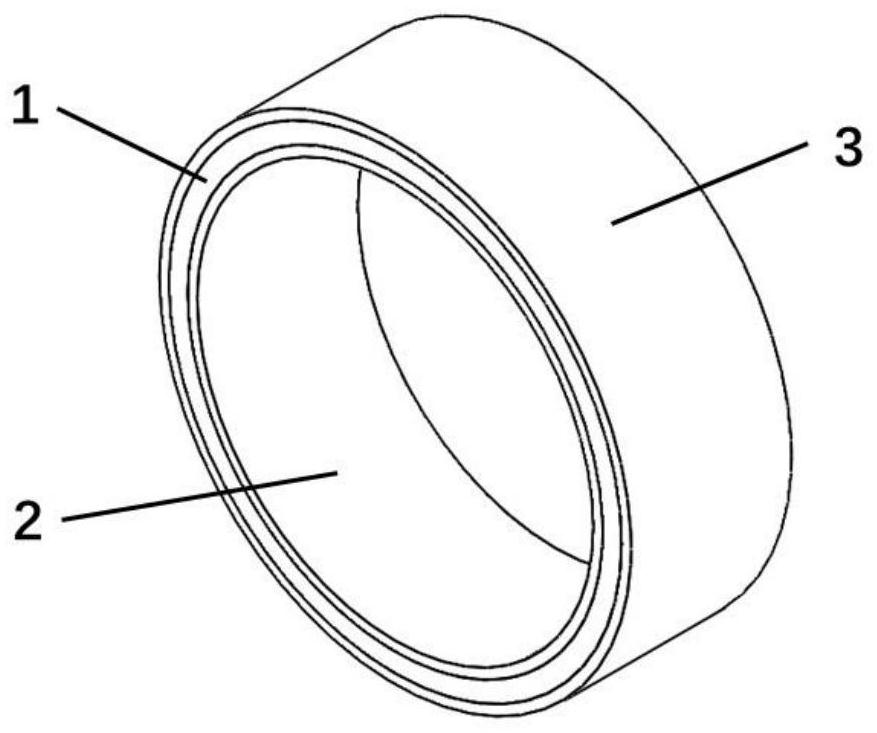

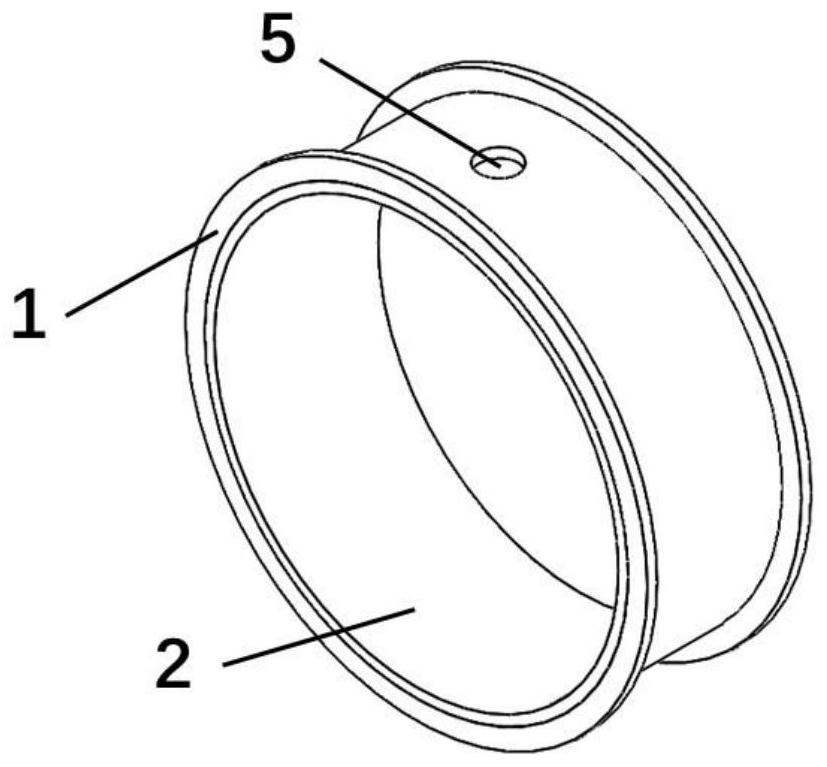

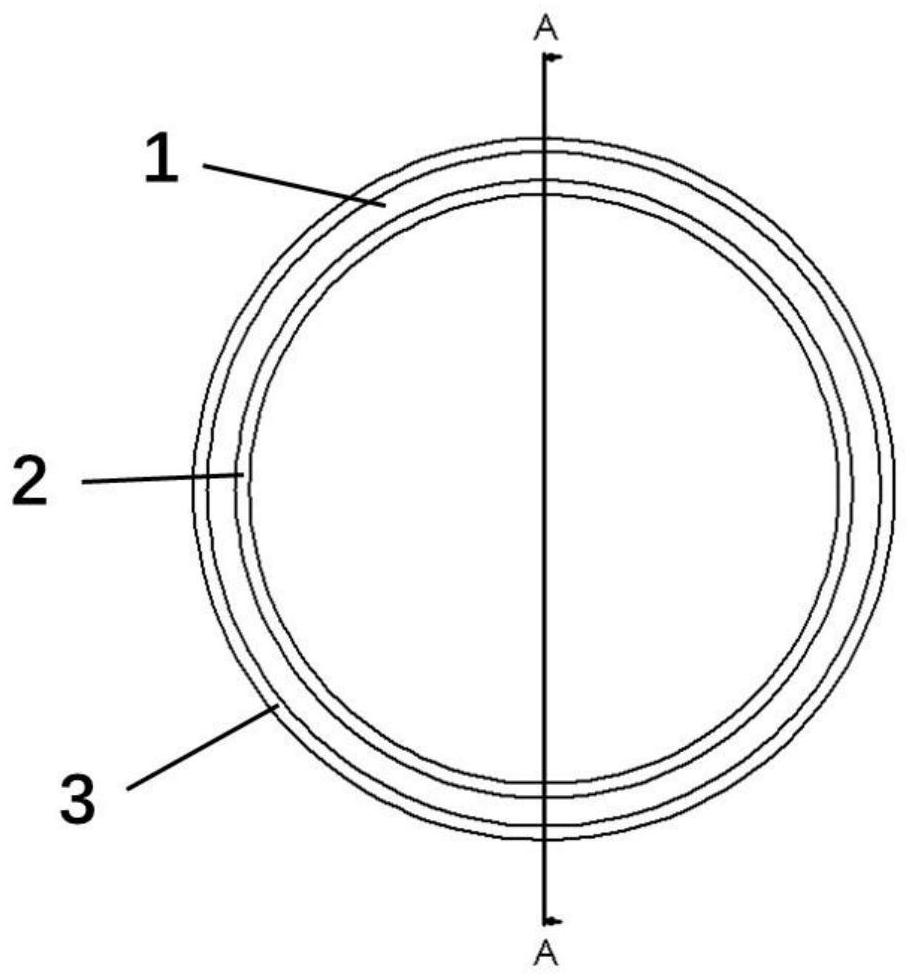

[0028] Such as Figure 1~4 As shown, the ultra-thin low-frequency ventilated acoustic sound-absorbing unit of the present invention includes an annular shell, specifically a circular outer shell 3, a circular inner shell 2, and an upper shell 1 and a lower shell 4 connecting the inner and outer shells. , the inner housing 2 is nested inside the outer housing 3; so that the inside of the housing is provided with an annular cavity 6, and the inner wall of the housing (ie, the inner housing wall) is provided with a through hole 5 through which the cavity 6 passes. The hole 5 communicates with the outside world; the through hole 5 serves as a short tube.

[0029] In actual use, several sound-absorbing units can be used to form a sound absorber, and the sound absorbers are closely arranged and connected in sequence along the sound propagation direction. The characteristic si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com