Novel black tea production process

A production process and technology of black tea, applied in the field of new-type black tea production process, can solve the problems that fresh leaves cannot be fully rolled, lack of scientific technical conditions and means, sour and astringent taste cannot be removed, etc., and achieve strong, fresh and refreshing taste The effect of stable quality and ruddy color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

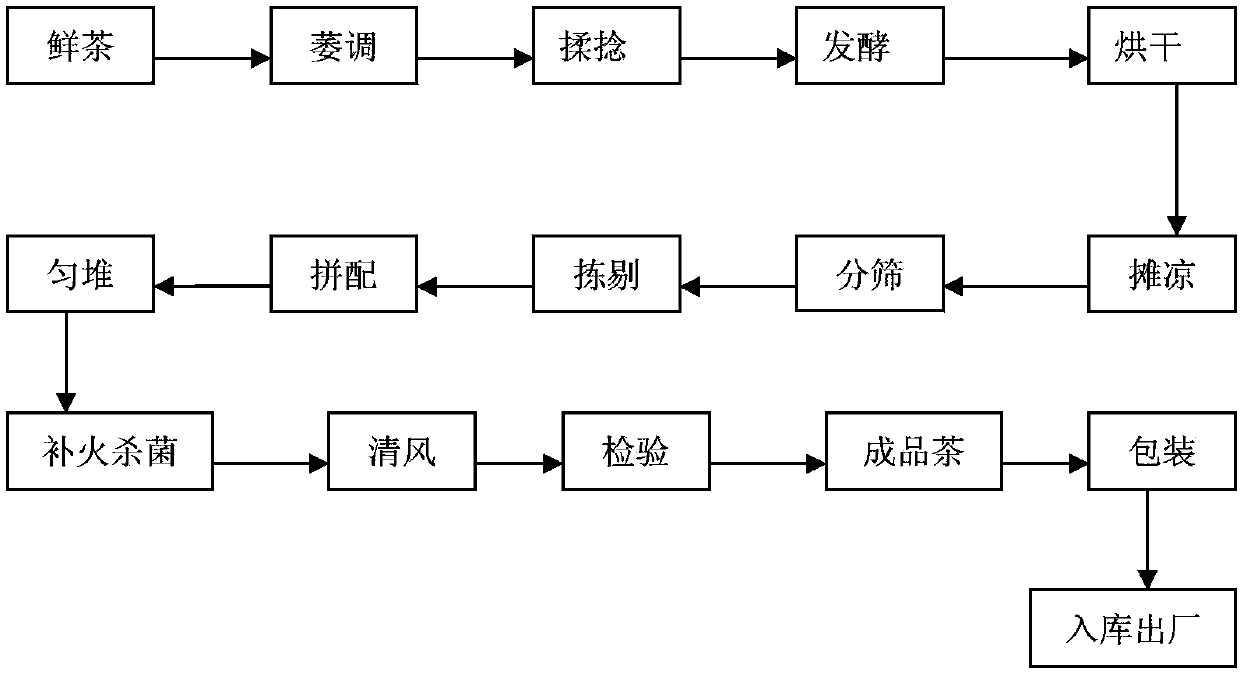

[0015] Such as figure 1 As shown, the novel black tea production process described in the embodiment of the present invention includes: fresh tea, withering, rolling, fermentation, drying, cooling, sub-sieving, picking, blending, heaping, and fire repair Sterilization, fresh air, inspection, finished tea, packaging, warehousing and delivery, including:

[0016] In the withering step, the thinning thickness of fresh leaves is less than 3cm, the room temperature is 25 degrees Celsius, and the withering time is 10-12 hours;

[0017] In the kneading step, the fresh leaves are naturally placed in the kneading device, and the top of the fresh leaves is 3cm-5cm away from the kneading cover; kneading adopts the principle of light-heavy-light pressure, no pressure is applied at the beginning of kneading, and the pressure is added after 30 minutes of kneading. Pressing, during the pressurization process, press and loose alternately, press for 10 minutes, loose for 5 minutes, after repe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com