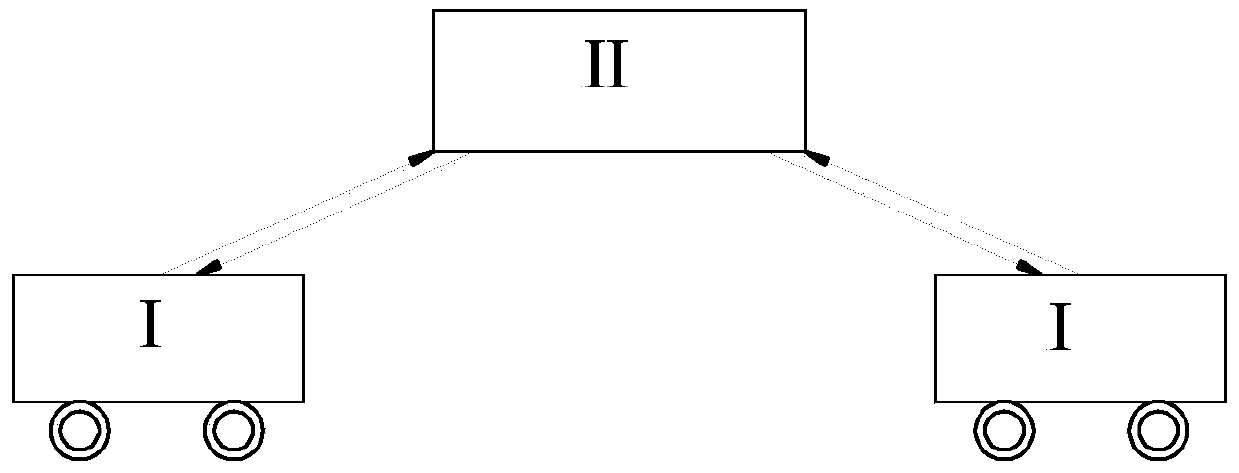

Mobile enrichment-fixing catalytic oxidation type organic waste-gas treating apparatus

A catalytic oxidation and organic waste gas technology, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve secondary pollution, adsorbers cannot be regenerated and reused, and adsorbents cannot be regenerated and reused. To achieve the effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

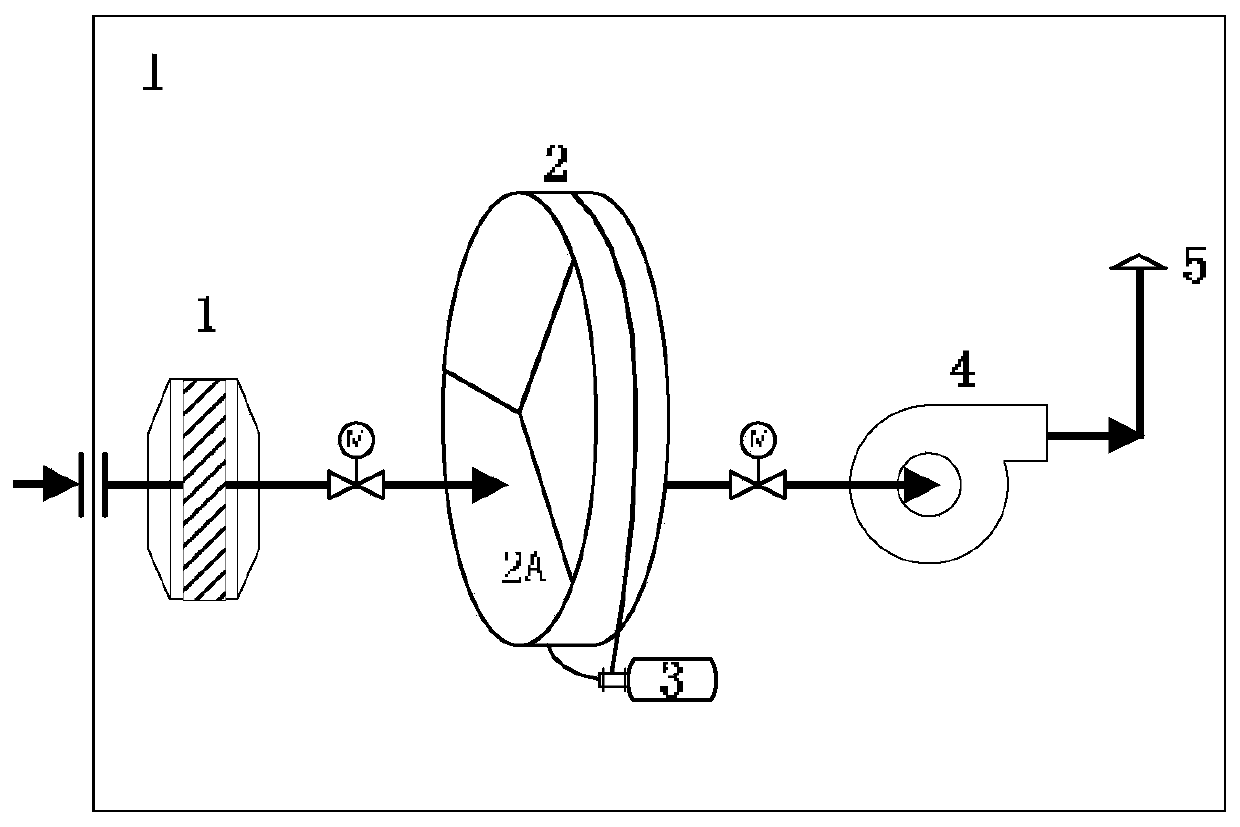

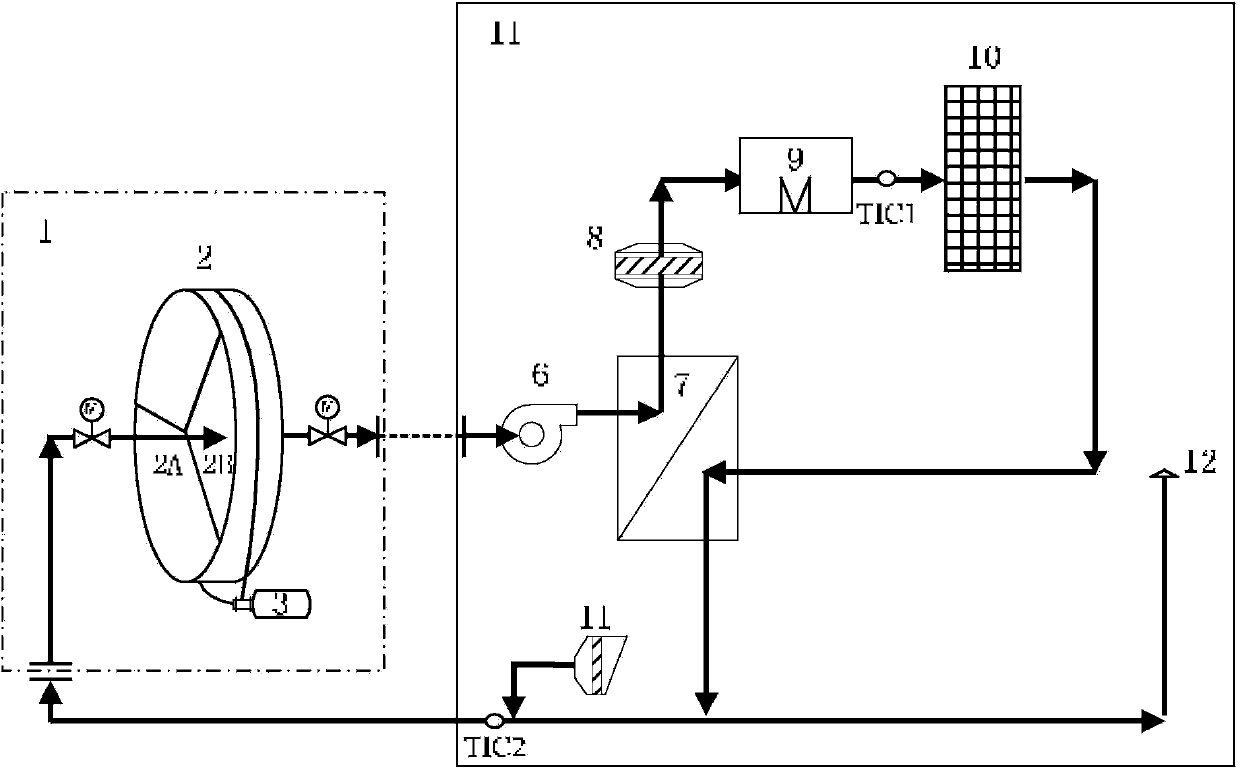

[0040] The working steps of the mobile enrichment device I at the pollution source site:

[0041] The working process of the adsorption operation is: the valves at the adsorption inlet and the adsorption outlet of the adsorption bed 2 are opened, the adsorption fan 4 makes the whole system generate negative pressure, and the organic waste gas is sucked in from the inlet of the filter 1, and the exhaust gas contains The dust is removed by the filter. The purpose of the filter is to prevent particles such as dust from clogging the gaps of the adsorbent in the adsorption bed 2 and affecting the adsorption effect; then, the waste gas enters the adsorption bed 2 from the adsorption inlet, and the organic matter Adsorbed by the adsorbent in the adsorption bed 2, the exhaust gas is purified; finally, the purified exhaust gas is extracted by the adsorption fan 4 and discharged through the adsorption high-altitude discharge branch 5 up to the standard.

[0042] After the mobile enrichm...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap