A kind of multi-layer composite functional material and its preparation method and application

A functional material and multi-layer composite technology, applied in the field of environmental purification, can solve the problems that are difficult to apply in relatively shading places, can not be used normally day and night, and require high light, and achieve the effect of increasing beneficial microorganisms, large surface area, and high photocatalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

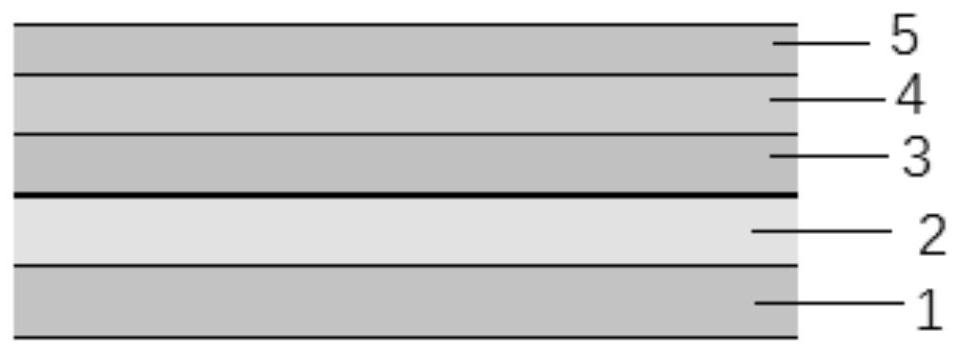

[0041] A multi-layer composite functional material, the functional material is, from bottom to top, a base material layer, a solar reflection layer, a photocatalytic layer, a biological coupling purification layer and a self-cleaning protective layer;

[0042] The solar reflection layer is made of mica-modified silica sol;

[0043] The photocatalytic layer is prepared from a photocatalytic nanogel of rare earth co-doped graphene;

[0044] The biological coupling purification layer contains trace element biological activation factors;

[0045] The self-cleaning protective layer contains ethyl cellulose;

[0046] The preparation method of the functional material comprises the following steps:

[0047] (1) prepare mica-modified silica sol;

[0048] 5kg of mica crystals were added to 160L of nano-silica ethanol dispersion liquid (the mass concentration of nano-silica was 5%), followed by high-speed stirring and ultrasonic dispersion to obtain mica-modified silica sol.

[0049] (...

Embodiment 2

[0067] The difference from Example 1 is that the prepared rare earth element co-doped graphene photocatalytic nanogel is coated on the non-woven substrate supported by the previous slurry, and the coating times are 2 times.

Embodiment 3

[0069] The difference from Example 1 is that 0.4 g of graphene is added to the gel D, and the rare earth element co-doped graphene photocatalytic nanogel is obtained by ultrasonic treatment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com