Hot stamping forming process based on Q&P one-step method

A technology of hot stamping forming and hot stamping, which is applied in the field of hot stamping forming technology based on Q&P one-step method, which can solve the problems of low strength and plasticity, poor plasticity (poor elongation), and achieve improved elongation and impact resistance. , Good effect of comprehensive impact resistance mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

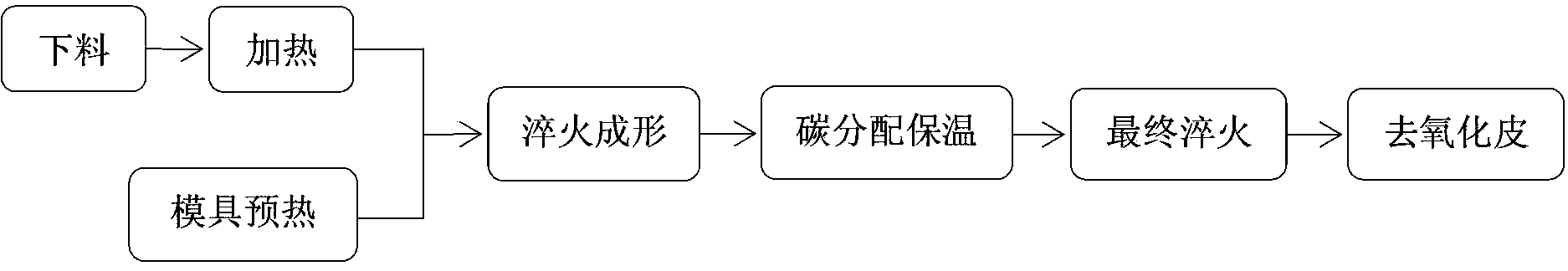

[0019] The material is the hot stamping steel B1500HS produced by Baosteel as an example. One-step hot stamping process based on Q&P, such as figure 1 shown, including the following steps:

[0020] 1) Cutting: cutting B1500HS sheets according to hot stamping parts;

[0021] 2) Mold preheating: heat the mold with heating plate to 250°C;

[0022] 3) Heating: put the sheet into the heating furnace, vacuumize, and heat the sheet to

[0023] 920°C, keep warm for 5 minutes to make the sheet austenitized evenly;

[0024] 4) Hot stamping forming: quickly move the heated sheet to the hot stamping die, use a 100T hydraulic press for stamping and quenching, keep the mold closed, carry out carbon distribution and heat preservation at 250°C for 40s, and perform Q&P one-step processing;

[0025] 5) Final quenching: open the mold, take out the hot stamping parts after carbon distribution and heat preservation, and quickly put them into water to quench to room temperature;

[0026] 6) De...

Embodiment 2

[0028] The hot stamping forming process based on Q&P one-step method is an integrated process of Q&P heat treatment process and hot stamping process, which specifically includes the following steps:

[0029] (1) Cutting: cutting the sheet according to the size of the hot stamping part;

[0030] (2) Mold preheating: heat the mold with the heating plate to 230°C;

[0031] (3) Heating: Put the sheet into the heating furnace, vacuumize, heat the sheet to 900°C at a heating rate of 15°C / s, and keep it warm for 6 minutes to make the sheet evenly austenitized;

[0032] (4) Hot stamping forming and in-mold quenching: Quickly move the heated sheet to the preheated hot stamping die for stamping and quenching. Since the temperature of the mold is much lower than the temperature of the sheet, it is completed while forming. in-mold quenching process;

[0033] (5) Carbon distribution: keep the mold closed and keep warm at 230°C for 180s;

[0034] (6) Final quenching: the hot stamping par...

Embodiment 3

[0037] The hot stamping forming process based on Q&P one-step method is an integrated process of Q&P heat treatment process and hot stamping process, which specifically includes the following steps:

[0038] (1) Cutting: cutting the sheet according to the size of the hot stamping part;

[0039] (2) Mold preheating: heat the mold with heating plate to 410°C;

[0040] (3) Heating: Put the sheet into the heating furnace, vacuumize, heat the sheet to 950°C at a heating rate of 16°C / s, and keep it warm for 3 minutes to make the sheet evenly austenitized;

[0041] (4) Hot stamping forming and in-mold quenching: Quickly move the heated sheet to the preheated hot stamping die for stamping and quenching. Since the temperature of the mold is much lower than the temperature of the sheet, it is completed while forming. in-mold quenching process;

[0042] (5) Carbon distribution: keep the mold closed and keep warm at 410°C for 10s;

[0043] (6) Final quenching: the hot stamping parts af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com