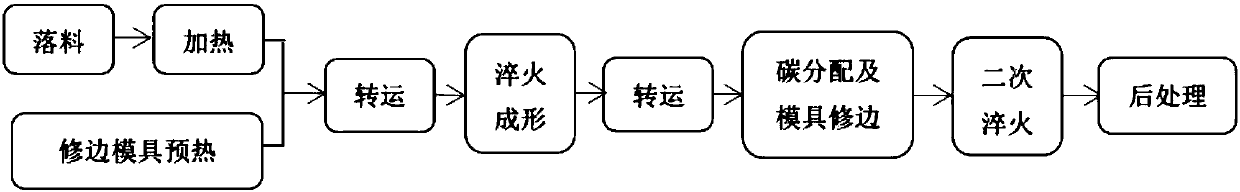

Integrated process of hot-stamping and die trimming

A technology of hot stamping forming and hot stamping, which is applied in the direction of forming tools, heat treatment furnaces, manufacturing tools, etc., can solve the problem of high cost per piece, and achieve the effects of simple design, reduced trimming resistance, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The material is the hot stamping steel B1500HS produced by Baosteel as an example. Based on an integrated process of ultra-high-strength steel hot stamping and die trimming, such as figure 1 shown, including the following steps:

[0034] (1) Blanking: cutting B1500HS sheets according to hot stamping parts;

[0035] (2) Mold preheating: heat the trimming mold with a heating plate to 350°C;

[0036] (3) Heating: Put the sheet into a heating furnace, vacuumize, heat the sheet to 920°C at a heating rate of 20°C / s, and keep it warm for 5 minutes to make the sheet evenly austenitized;

[0037] (4) Primary transfer: remove the heated sheet from the heating furnace and transfer it to the hot stamping mold;

[0038] (5) Hot stamping forming and primary quenching in the mold: Use a 100-ton (T) hydraulic press for stamping forming quenching, keep the mold closed, control the downward speed of the press, and complete stamping forming quenching until the temperature of the part d...

Embodiment 2

[0044] Based on an integrated process of ultra-high-strength steel hot stamping and die trimming, the process is an integrated process of hot stamping forming process, Q&P heat treatment process and die trimming process, which specifically includes the following steps:

[0045] (1) Blanking: cutting 27SiMn sheet according to the size of hot stamping parts;

[0046] (2) Mold preheating: heat the trimming mold with a heating plate to 400°C;

[0047](3) Heating: Put the sheet into the heating furnace, vacuumize, heat the sheet to 900°C at a heating rate of 5°C / s, and keep it warm for 6 minutes to make the sheet evenly austenitized;

[0048] (4) Primary transfer: remove the heated sheet from the heating furnace and transfer it to the hot stamping mold;

[0049] (5) Hot stamping and quenching in the mold: Use a 200T servo press for hot stamping quenching, keep the mold closed, control the downward speed of the press, and complete stamping quenching until the temperature of the par...

Embodiment 3

[0055] An integrated process of hot stamping and mold trimming, the process of which is as follows figure 1 As shown, the following steps are taken:

[0056] (1) Blanking: cutting the sheet according to the size of the hot stamping part;

[0057] (2) Preheating of the trimming mold: heating the trimming mold to 200°C and keeping it warm;

[0058] (3) Heating: put the sheet into a vacuum heating furnace for heating, the heating speed is not lower than 5°C / s, heat the sheet to 900°C, and keep it warm for 6 minutes to make the austenitization of the sheet even;

[0059] (4) Primary transfer: move the heated sheet out of the vacuum heating furnace and transfer it to the hot stamping mold;

[0060] (5) Hot stamping forming and one-time quenching in the mold: start the press, control the downward speed of the press, and complete stamping quenching until the temperature of the part drops to 200°C;

[0061] (6) Secondary transfer: move the hot stamping parts out of the hot stamping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com