NID desulfurized fly ash wet-grinding modified mineral powder and preparation method thereof

A technology for desulfurization ash and mineral powder, which is applied in the field of NID desulfurization ash wet grinding modified mineral powder and its preparation, can solve the problems of decreased strength of slag powder and cannot be directly applied, and achieves improved mechanical properties, high value-added utilization, The effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Example 1 The weight of each component in NID desulfurized ash wet milled modified slag powder is: 1 ton of desulfurized ash, 99 tons of slag powder, and 7 tons of water.

[0014] Embodiment 1 NID desulfurization ash wet grinding modified mineral powder preparation method, comprising the following steps:

[0015] 1) Weigh the desulfurization ash and slag powder respectively according to the ratio;

[0016] 2) Mix the weighed desulfurization ash and slag powder evenly, and add the water in the stated proportion and mix evenly;

[0017] 3) Grind the mixture homogeneously mixed in the previous step for 22 minutes in a mill to obtain the desulfurized ash wet-milled modified mineral powder.

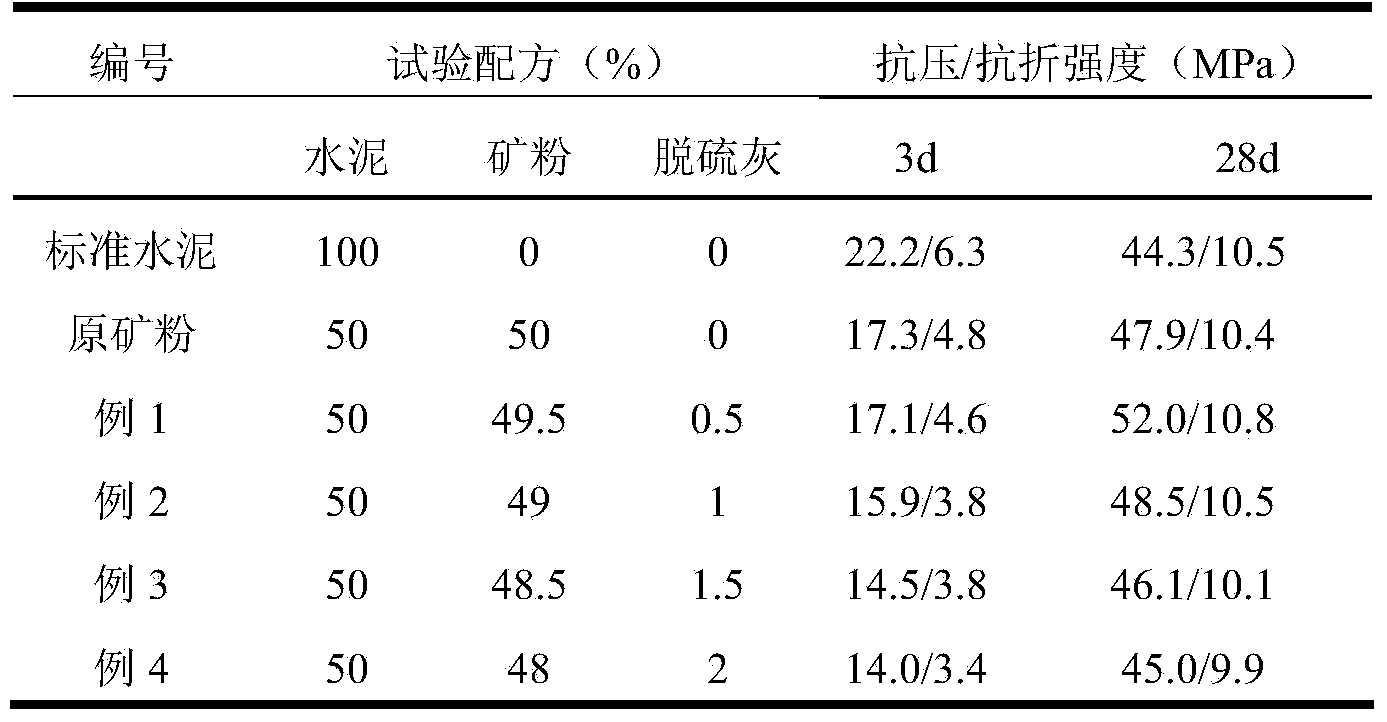

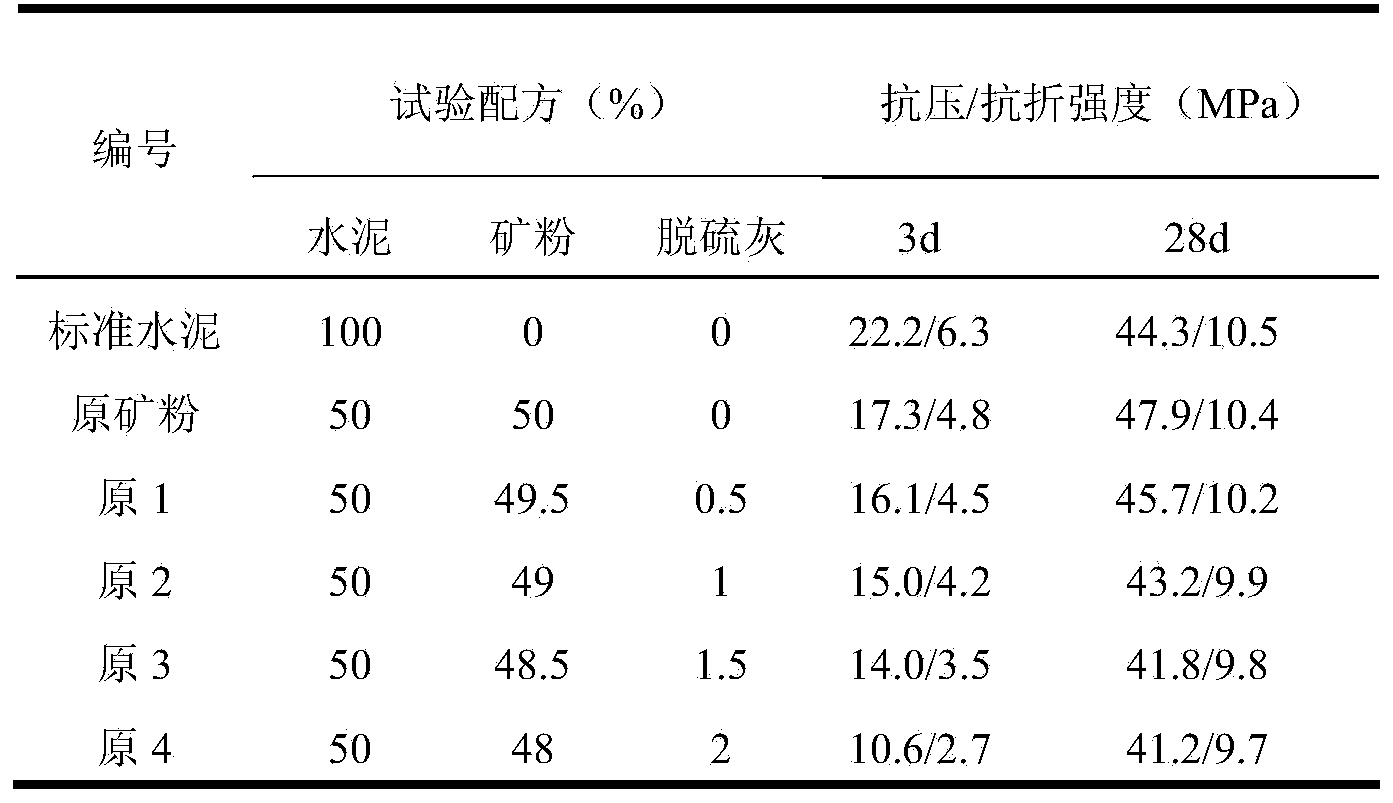

[0018] By comparing Table 1 and Table 2, it can be seen that the desulfurization ash wet-milled modified ore powder (Example 1 in Table 1) using the formula of this example is comparable to the desulfurization ash ore powder (original 1 in Table 2) mixed with the same quality of the pr...

Embodiment 2

[0020] Example 2 The weight of each component in NID desulfurized ash wet milled modified slag powder is: 2 tons of desulfurized ash, 98 tons of slag powder, and 9 tons of water.

[0021] Embodiment 2 The preparation method of NID desulfurization ash wet grinding modified mineral powder, comprising the following steps:

[0022] 1) Weigh the desulfurization ash and slag powder respectively according to the ratio;

[0023] 2) Mix the weighed desulfurization ash and slag powder evenly, and add the water in the stated proportion and mix evenly;

[0024] 3) Grind the mixture homogeneously mixed in the previous step for 18 minutes in a mill to obtain wet-milled modified mineral powder of desulfurization ash.

[0025] By comparing Table 1 and Table 2, it can be seen that the desulfurization ash wet-milled modified slag powder (Example 2 in Table 1) using the formula of this example is comparable to the desulfurization ash slag powder mixed with the same quality of the prior art (For...

Embodiment 3

[0027] Example 3 The weight of each component in NID desulfurized ash wet milled modified slag powder is: 3 tons of desulfurized ash, 97 tons of slag powder, and 8 tons of water.

[0028] Embodiment 3 NID desulfurization ash wet grinding modified mineral powder preparation method, comprising the following steps:

[0029] 1) Weigh the desulfurization ash and slag powder respectively according to the ratio;

[0030] 2) Mix the weighed desulfurization ash and slag powder evenly, and add the water in the stated proportion and mix evenly;

[0031] 3) Grind the mixture homogeneously mixed in the previous step for 20 minutes in a mill to obtain the desulfurized ash wet-milled modified mineral powder.

[0032] By comparing Table 1 and Table 2, it can be seen that the desulfurization ash wet-milled modified slag powder (Example 3 in Table 1) using the formula of this example is comparable to the desulfurization ash slag powder mixed with the same quality of the prior art (Form 3 in Ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com