Ultrasonic door panel welding machine

A welding machine and ultrasonic technology, used in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of large volume, poor welding effect, and complex structure of the boom assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

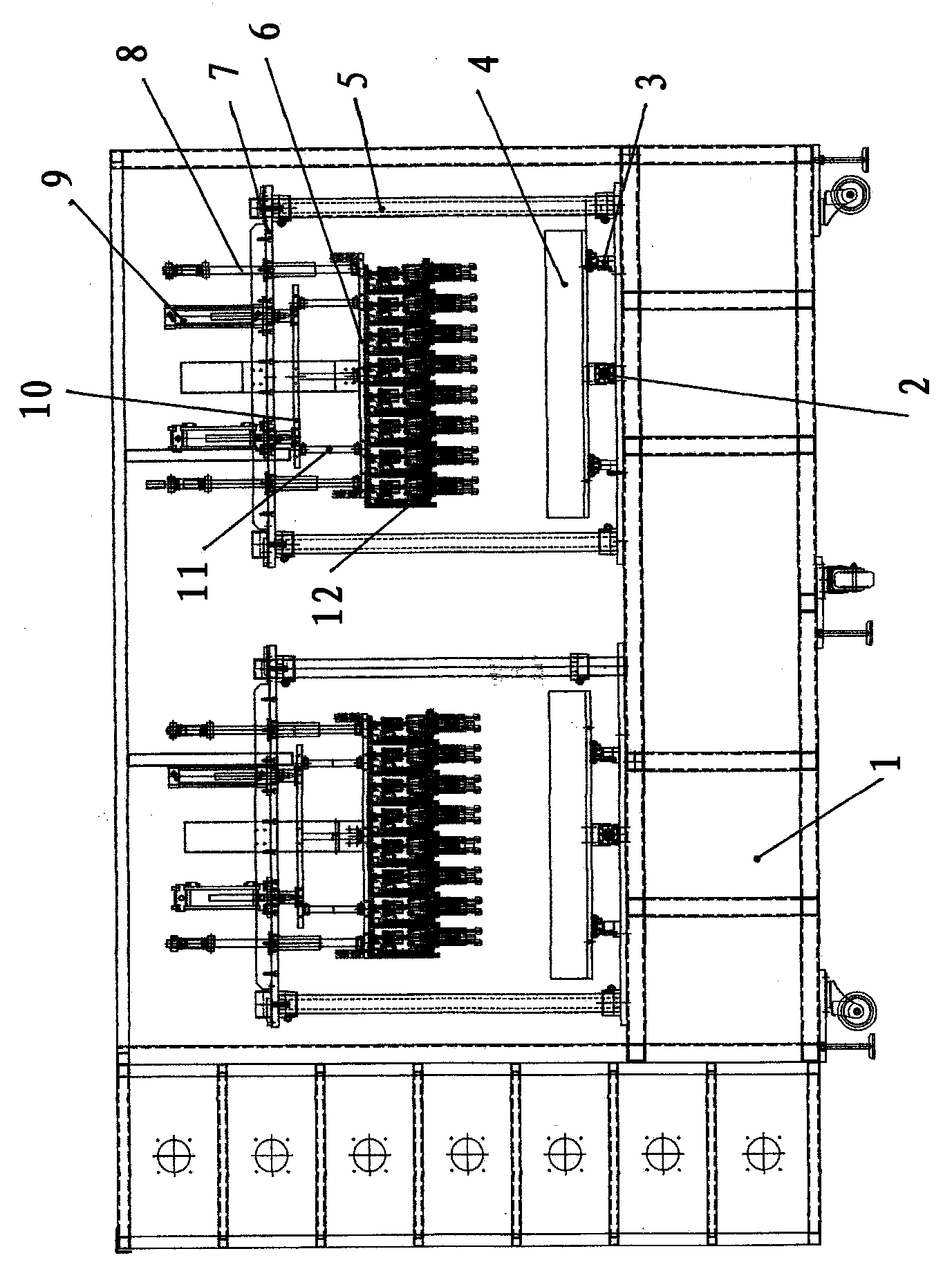

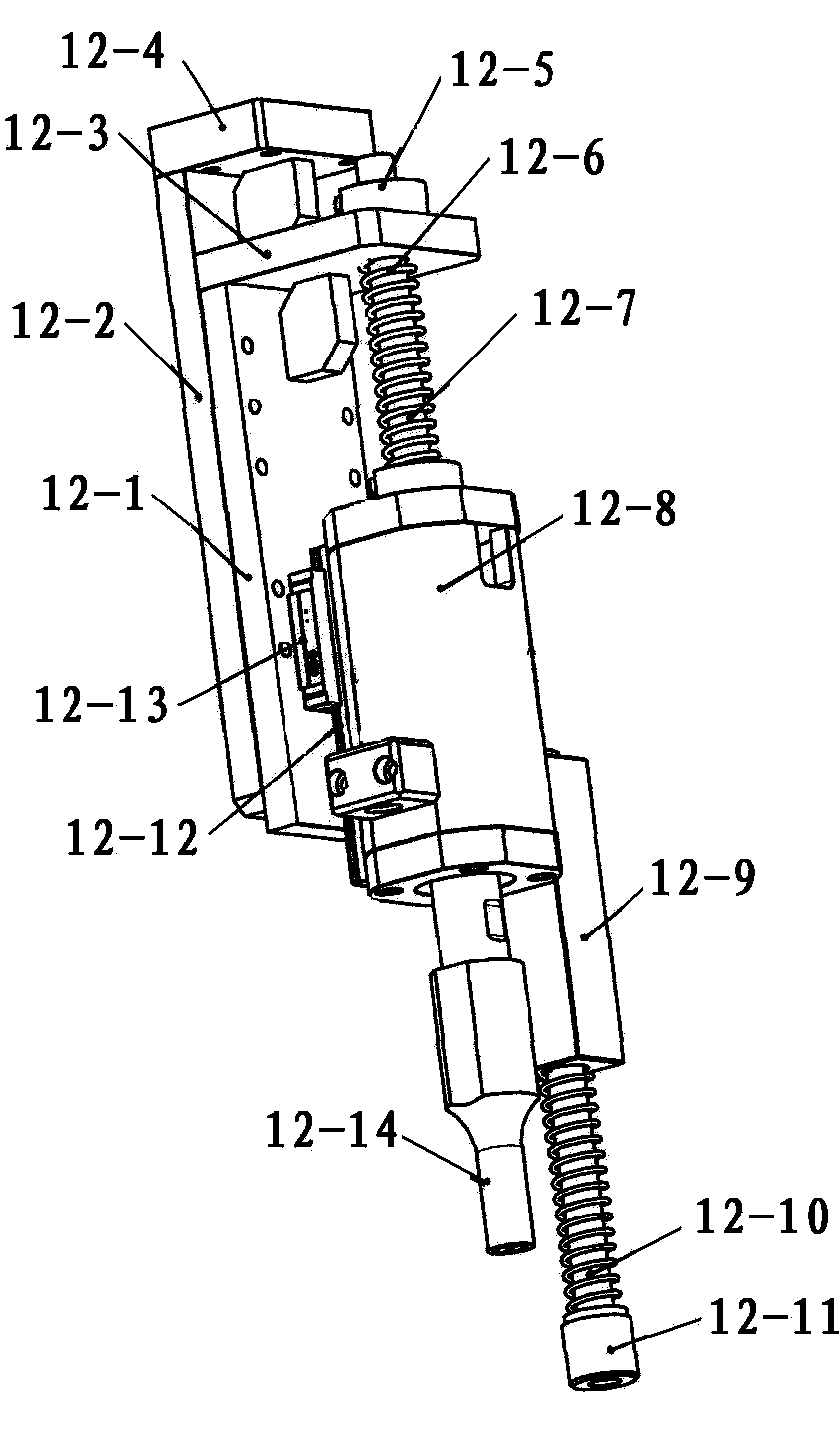

[0010] refer to figure 1 , it comprises frame 1, and several front and rear motion control cylinders 2 and several bottom dies 4 are fixed on the frame, and the bottom of each bottom die has guide rail, and guide rail is placed in guide rail seat 3, and guide rail seat is fixed on On the frame, each bottom mold is connected and fixed with the cylinder rod ends of one or two front and rear motion control cylinders; it also includes several crossbeams 7, and each crossbeam 7 is fixed on the frame by a column 5. It includes several upper and lower motion control cylinders 9, the cylinder body of each upper and lower motion control cylinder is fixed on the beam, and the bottom end of the cylinder rod of each upper and lower motion control cylinder is connected with a hanging plate 10, each There is a hanging plate fixing plate 6 under each hanging plate, and the hanging plate fixing plate is fixed on the hanging plate by a small column 11, and a guide rod 8 is fixed on the hanging...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com