Rotationally molded automobile chassis with steel-structured framework

A technology of automobile chassis and steel structure, applied in the superstructure, vehicle parts, transportation and packaging, etc., can solve the problems of reducing the weight of the chassis, danger, and the rigidity of the chassis does not meet the requirements, and achieves simplification of the production process, weight reduction, The effect of enhancing rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

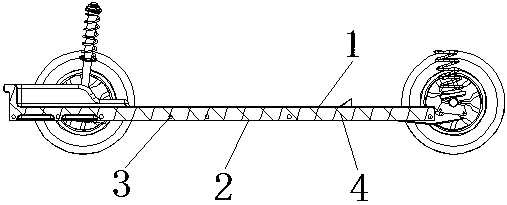

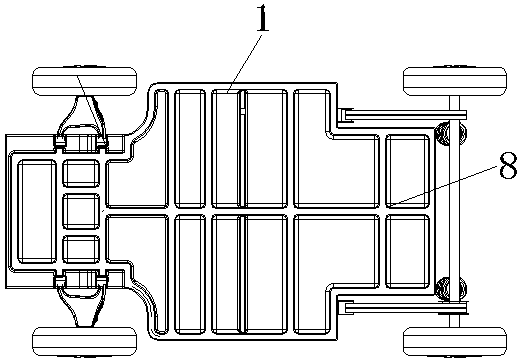

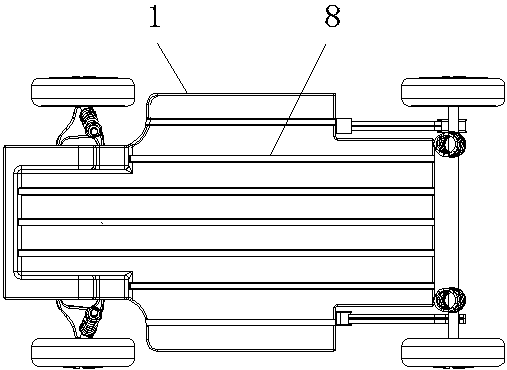

[0026] Such as Figure 1 to Figure 4 As shown, a rotomolded automobile chassis with a steel structure skeleton includes a chassis main body 1, and the chassis main body 1 includes a surface layer 2, a steel structure skeleton 3 and a central foam layer 4; the surface layer 2 is provided with Cavity, the central foam layer 4 is in the inner cavity of the surface layer; the steel skeleton structure 3 is arranged in the surface layer 2, and the steel skeleton structure 3 includes a general outline skeleton 5 and a cross bar 6 connected to the overall outline skeleton 5 and joystick 7. The upper surface and the bottom surface of the chassis main body 1 are respectively provided with protruding and grooved reinforcing rib structures 8; the chassis main body 1 is provided with inserts 9 for installing components.

[0027] The surface layer 2 of the chassis main b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com