Flue gas rapid cut-off device for coal charging cars and operating method of flue gas rapid cut-off device

A technology of quick cutting and coal loading trucks, applied in charging devices, furnace safety devices, petroleum industry, etc., can solve the problems of dust removal system without any protective operation, reset action can not be completed, dust removal pipeline explosion, etc. Safety and stability, avoidance of escalation, the effect of increasing the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

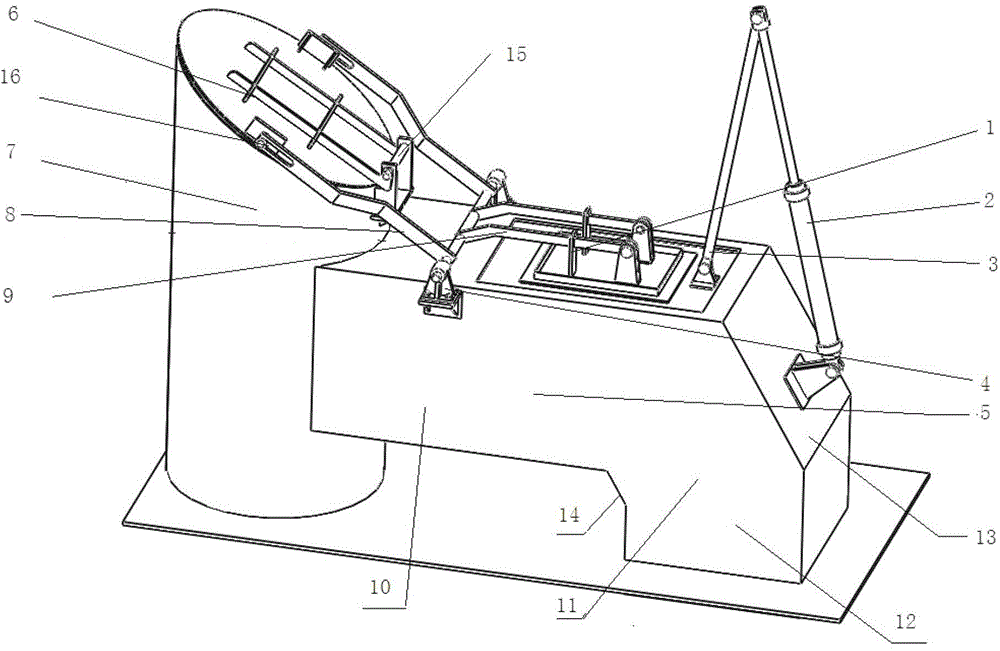

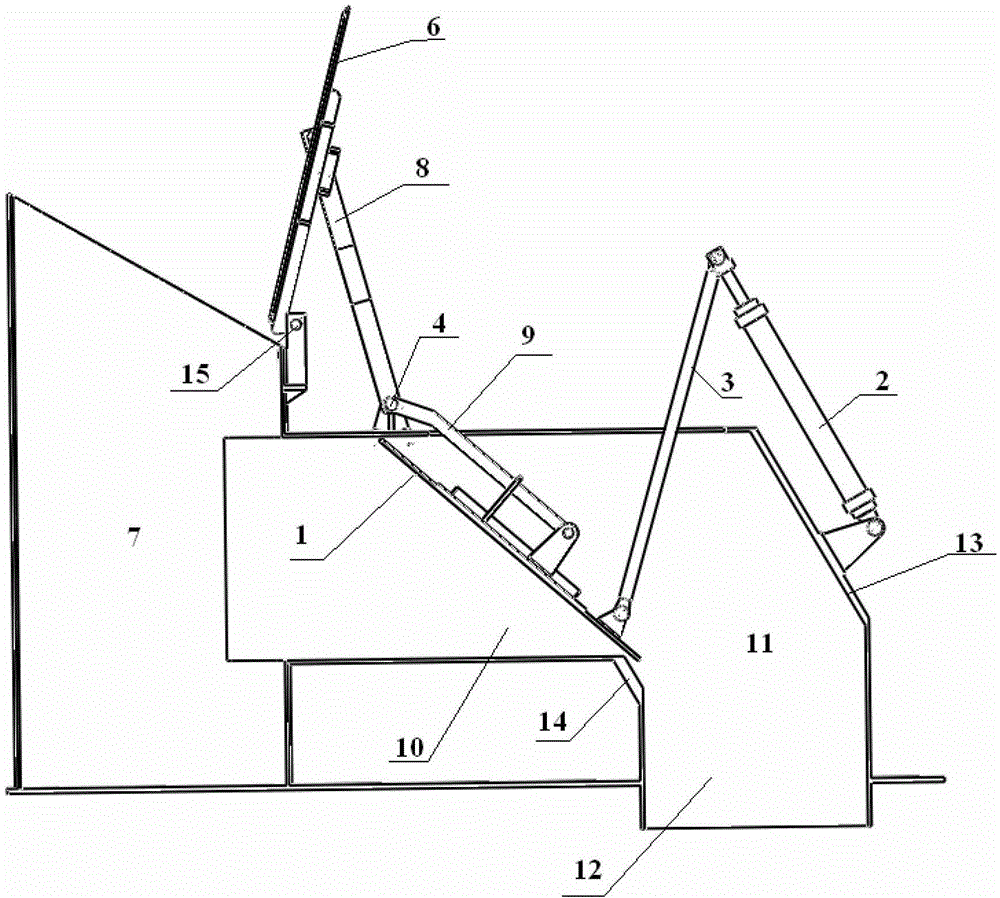

[0030] A quick cut-off device for flue gas of a coal loading vehicle, comprising a first dust removal pipeline connected to the coal loading vehicle, a second dust removal pipeline connected to a main dust removal pipe, and a driving device, the first dust removal pipeline and the second dust removal pipeline are perpendicular to each other Connected arrangement, a release cover is provided at the end of the first dust removal pipeline, and a smoke cut-off ram is provided on the pipe wall perpendicular to the first dust removal pipeline in the second dust removal pipeline, the release cover and the smoke gas The cut-off ram is connected through the linkage of the drive device:

[0031] When the flue gas cut-off ram is turned inside the second dust removal pipeline to cover the second dust removal pipeline, the flue gas cut-off ram is linked with the release cover to turn outwards and separates from the end of the first dust removal pipeline ;

[0032] When the flue gas cut-of...

Embodiment 2

[0037] As described in Example 1, a quick cut-off device for flue gas of a coal loading car, the difference is that the end of the primary dust removal pipeline forms an angle of 60° with the horizontal plane, and the diffusion cover is connected to the primary dust removal pipeline through a connecting shaft. The ends of the connecting rods are connected, and the first connecting rod is connected with the release cover through a sliding slot.

Embodiment 3

[0039] As described in Example 1, a quick cut-off device for smoke gas of a coal loading car, the difference is that when the smoke cut-off gate is turned over into the second dust removal pipeline, the smoke cut-off gate is set on the The lower end is on an inclined surface to cover the second dust removal duct.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com