Quickly-built steel springboard and method for preparing quickly-built steel springboard

A springboard and panel technology, applied in the direction of building structure support, building structure support, scaffolding accessories, etc., can solve the problems of insufficient structural strength and bearing capacity, insufficient firmness and stability, and inconvenient erection, so as to save use Quantity, reduce purchase cost, increase the effect of recycling value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

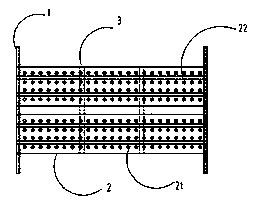

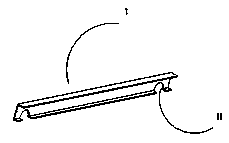

[0027] Please refer to figure 1 , a preferred embodiment of the quick-fit steel springboard of the present invention includes a load-bearing panel 2 and longitudinal beams 1 located on both sides of the load-bearing panel 2 and fixedly connected to the load-bearing panel. The stringer 1 is roughly formed in a "]" shape, which has two horizontal end faces and a vertical end face, which is formed with a concave portion. The bearing panel 2 is composed of several pieces of strip metal formed into a box-shaped structure, and several hollow convex holes 21 are evenly dispersed on the upper end surface, which can prevent slipping and be easy to clean; the bearing panel is fixed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com