Acoustic logging-while-drilling device of variable-diameter sound insulation structure

A drilling sound wave and sound insulation technology, which is applied in the field of sound wave logging while drilling devices, can solve the problems of drill collar strength damage, high processing cost and high cost, and achieves the advantages of reducing processing difficulty and cost, eliminating interference and enhancing mechanical strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

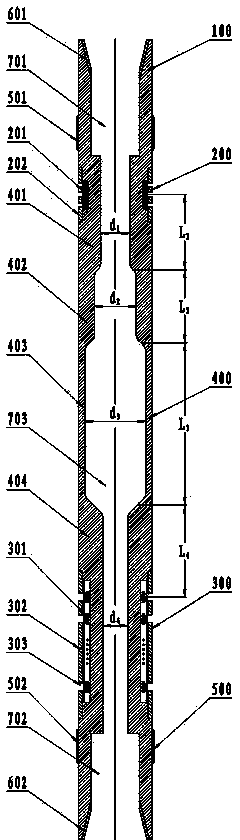

[0022] Such as figure 1 As shown, the variable-diameter sound insulation structure acoustic logging while drilling device includes a drill collar 100, and the outer side of the drill collar 100 is provided with an acoustic wave emitting device 200 and an acoustic wave receiving device 300; between the acoustic wave emitting device 200 and the acoustic wave receiving device 300 A variable-diameter sound insulator 400 is provided between them.

[0023] The distance between the drill collar 100 from the transmitting device 200 to the receiving device 300 is as follows: the first inner diameter d 1 , the first length L 1 The drill collar 401, the second internal diameter d 2 , the second length L 2 The drill collar 402, the third internal diameter d 3 , the third length L 3 The drill collar 403, the fourth internal diameter d 4 , the fourth length L 4 The drill collar 404; that is, the drill collar between the transmitting device 200 and the receiving device 300 has 3 diame...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com