Frame device for lifting and transporting tunneling head-on temporary bracket, and operation method

A temporary support and transportation technology, which is used in earth-moving drilling, mining equipment, tunnels, etc., to achieve the effects of short erection time, high degree of automation, and improved cutting time and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

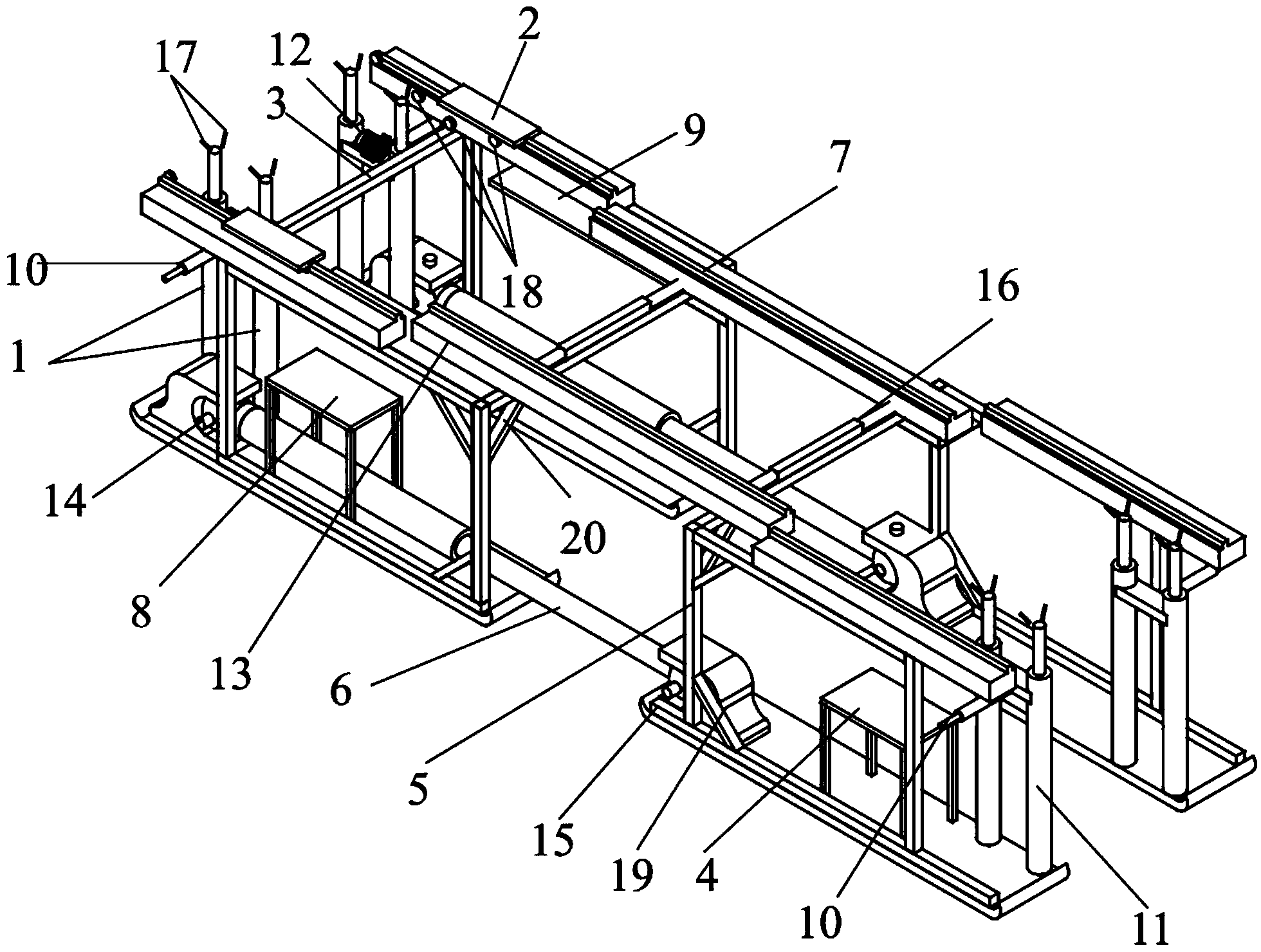

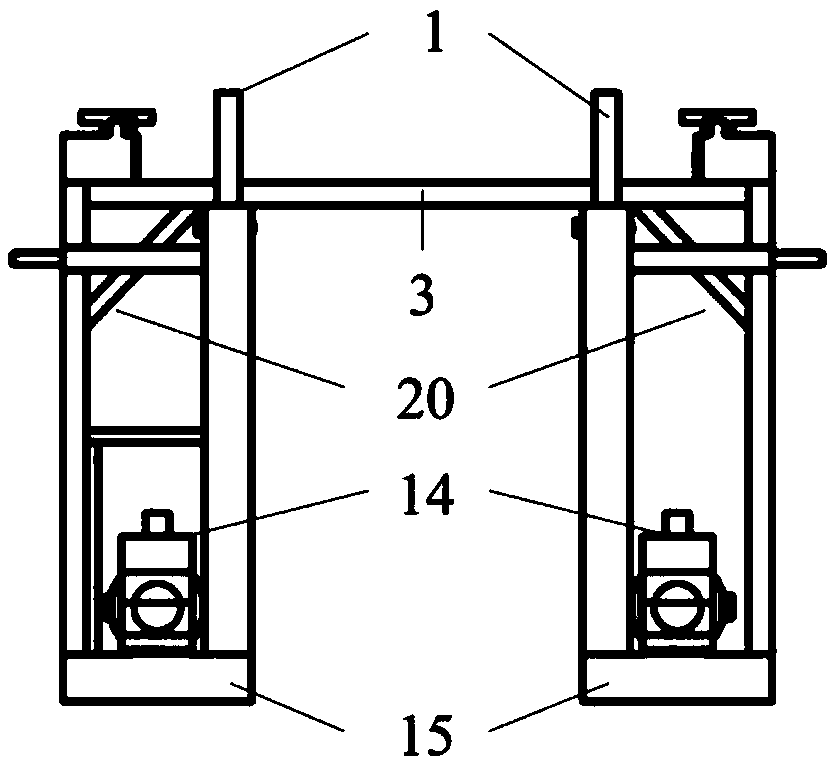

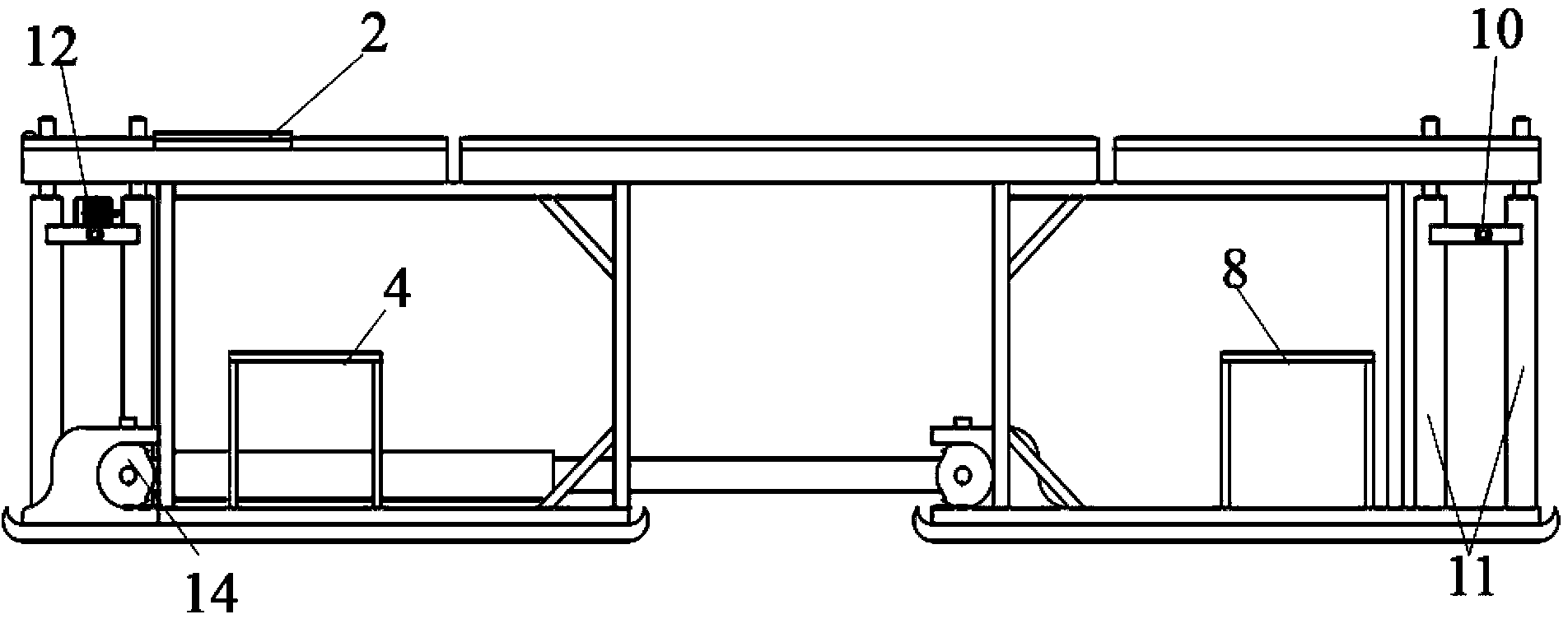

[0054] The present invention is described in detail below in conjunction with accompanying drawing:

[0055] Such as Figure 1-Figure 5 As shown, the self-moving frame device is used for the lifting and moving of the temporary support in the mine excavation working face. The device is composed of three parts: the hydraulic self-moving system, the carrier trolley 2, and the support lifting auxiliary system. The main function of the hydraulic self-moving system is to make the device move forward with the roadway excavation, the carrier trolley and its traction system move the temporary support 21 from the rear of the machine to the front of the machine, and the support lifting auxiliary system provides assistance for the lifting of the temporary support 21. The lower part of the device has enough space to meet the operation of the roadheader and its operators, as well as the layout of ventilation, dust removal, pipeline and other facilities, avoiding the empty top operation of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com