Water pond filter pump with high efficiency and low cost

A low-cost, high-efficiency technology, applied to the components, pumps, pump elements, etc. of the pumping device for elastic fluids, which can solve the problem of low efficiency, low flow rate of the pool filter pump, clockwise rotation and counterclockwise rotation, etc. problems, to achieve the effect of reducing manufacturing costs, reducing assembly links, and improving water efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

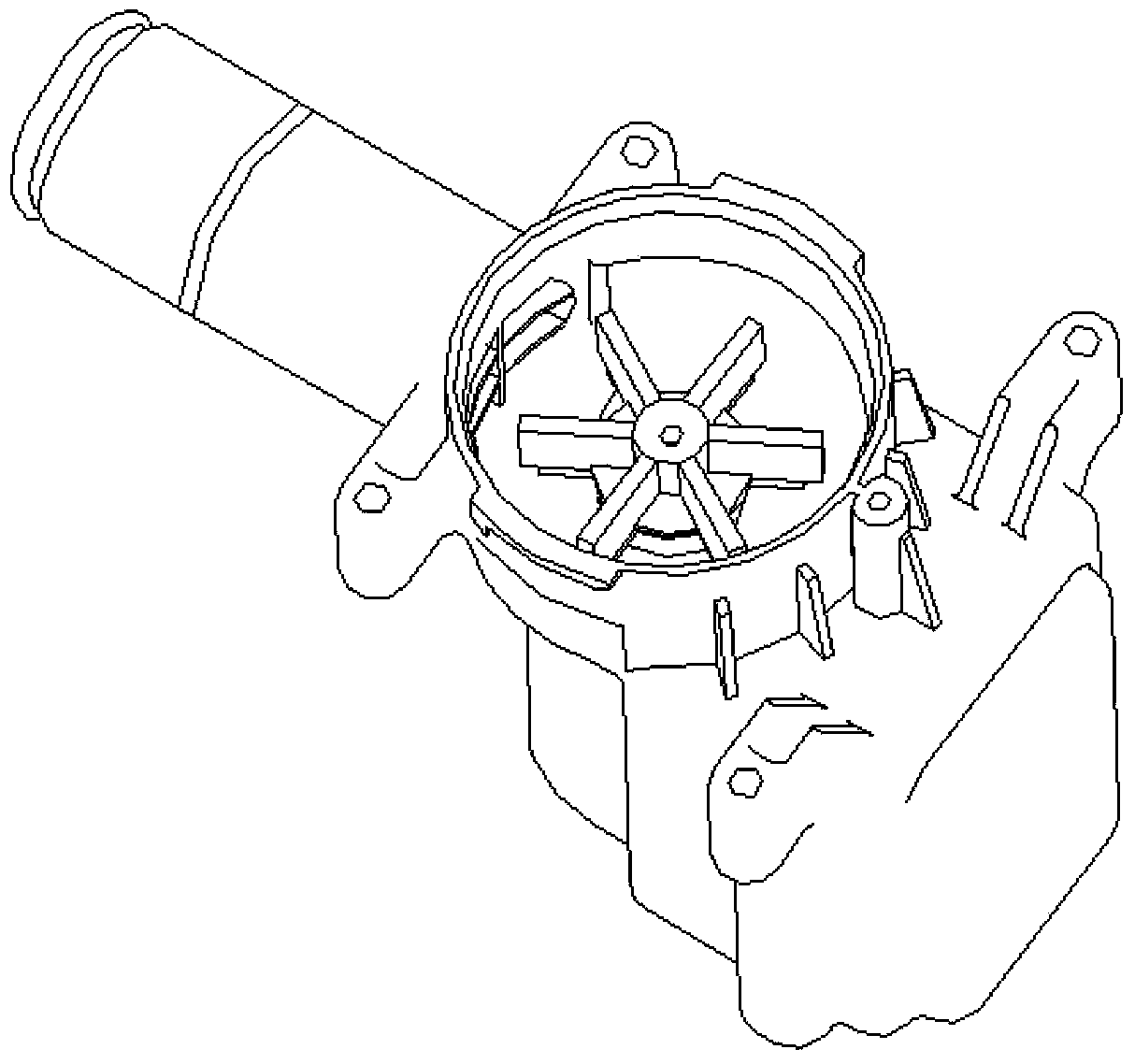

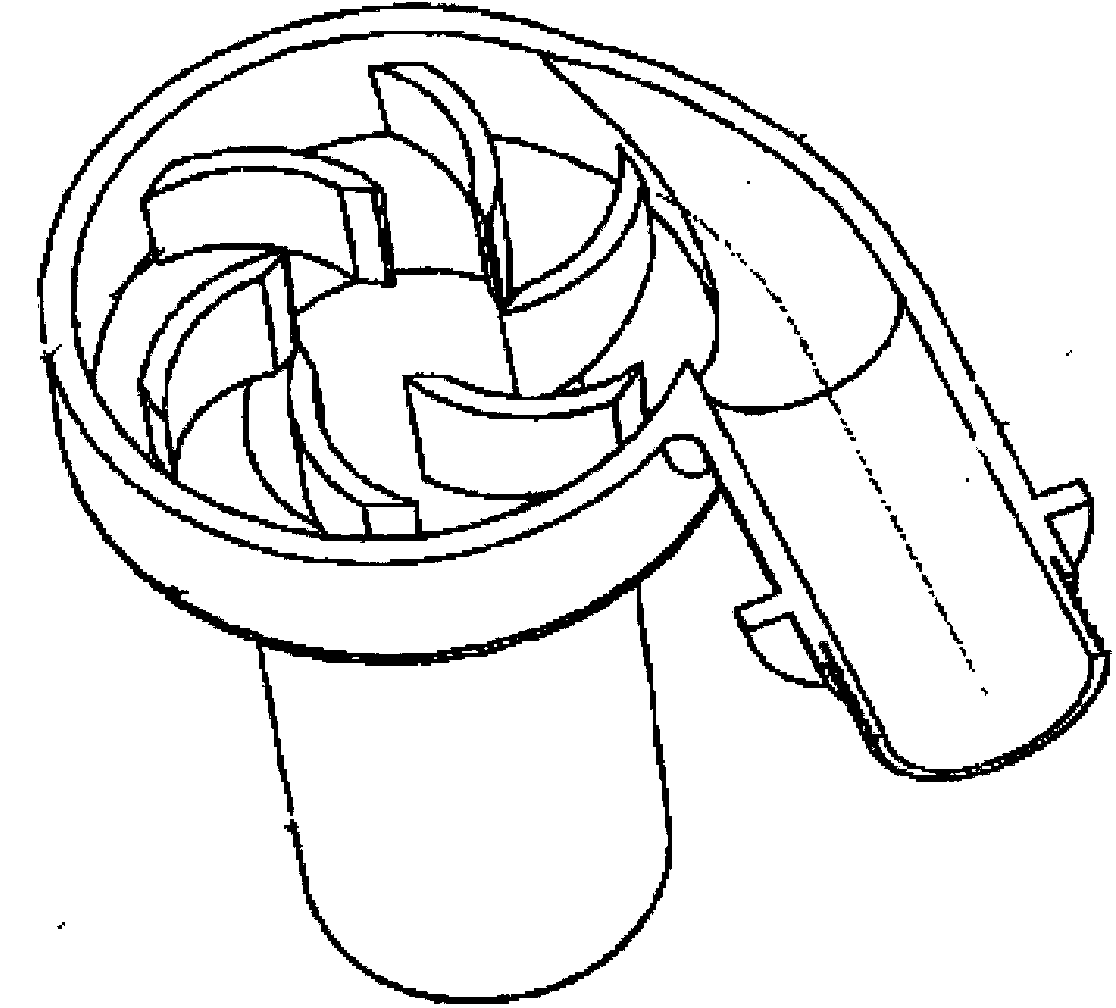

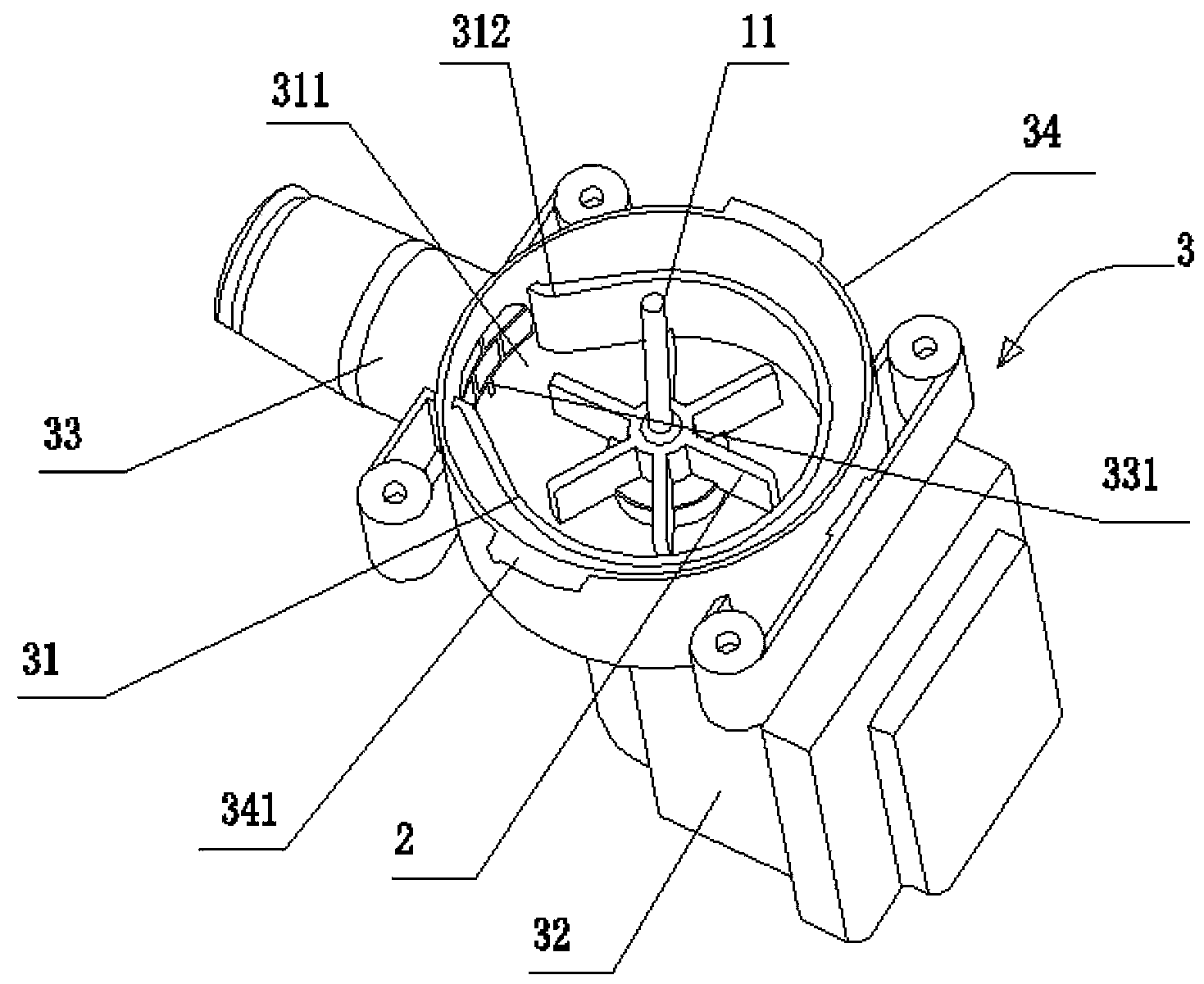

[0026] like image 3 , Figure 4 , Figure 5 , Image 6 and Figure 7 As shown, a high-efficiency and low-cost pool filter pump includes a motor 1, an impeller 2 and a motor housing 3, the impeller is sleeved on the rotor shaft 11 of the motor, and the motor housing includes a housing for the impeller. The annular impeller cavity 31 and the pump body 32 for accommodating the motor, a gap 311 is formed on one side of the impeller cavity, and the impeller cavity on both sides of the gap extends outwards to form an arc-shaped structure 312, the A water outlet pipe 33 is provided at the gap, and the water outlet pipe communicates with the impeller cavity through the gap. In this way, the connection between the impeller cavity and the outlet pipe is two outwardly extending arc structures, that is, compared with the impeller cavity, the position of the outlet pipe extends outward for a certain distance, through the above-mentioned double arc structure design of the impeller cavi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com