Constant-pressure concrete permeability testing device

A test device, concrete technology, applied in the direction of measurement device, permeability/surface area analysis, suspension and porous material analysis, etc., can solve the problems of complex operation, long time period, poor sealing, etc., and achieve high test accuracy and shorten the test time. The effect of experiment cycle and improving experiment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

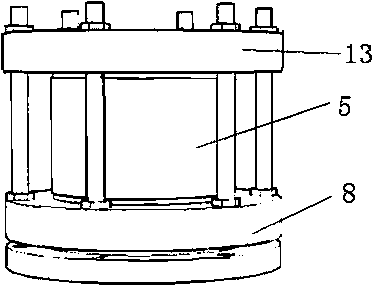

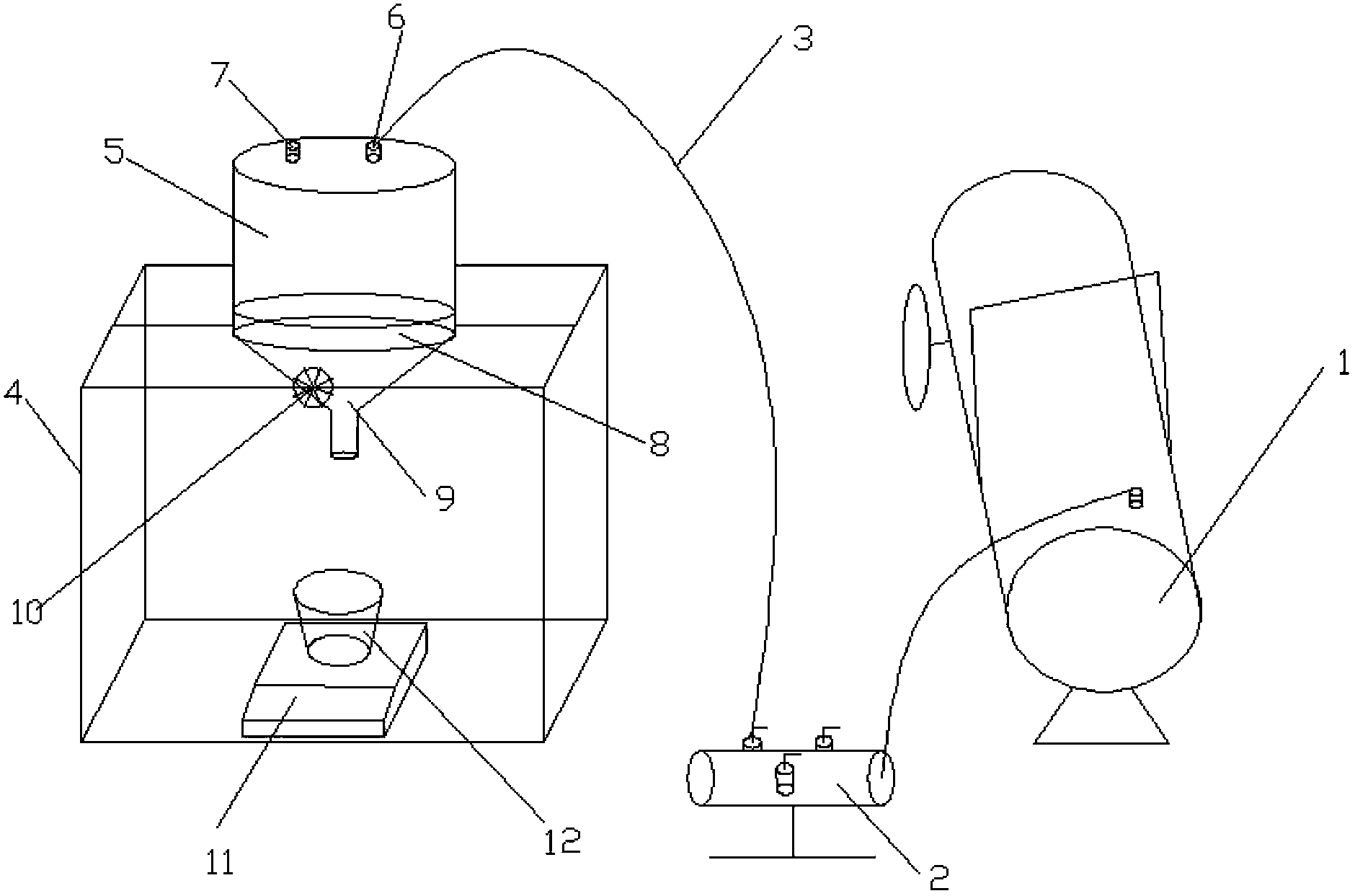

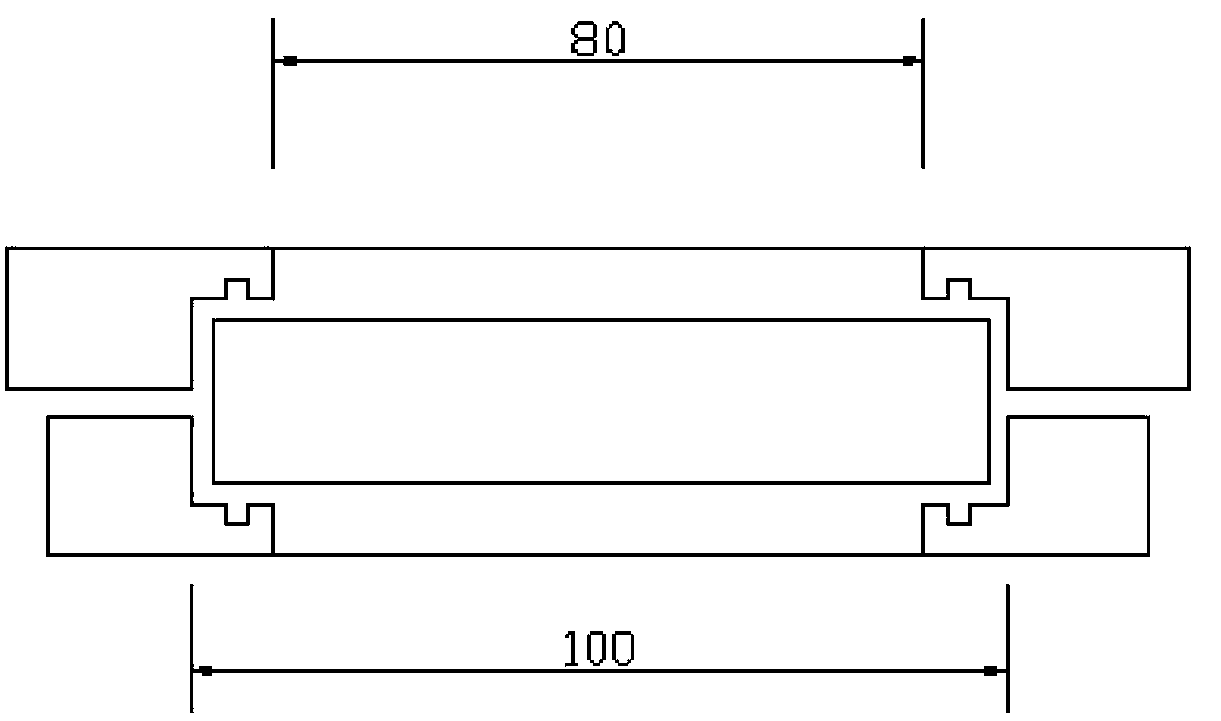

[0026] The constant-pressure concrete permeability test device includes a permeameter, and the permeameter is suspended and fixed on the support 4 through the fixing bolt 10 . Described permeameter comprises pressure water holding cylinder 5 and specimen groove 8; The material of described pressure water holding cylinder 5 is plexiglass, and this material is transparent and pressure-resistant, can observe the water in pressure water holding cylinder 5 through it. When the water content is insufficient, add water in time. The upper end of the pressure water tank 5 is closed and is provided with a pressure regulating valve 7 and an air intake valve 6; The air inlet valve 6 is used as a water inlet valve at the same time; the lower end of the pressure water container 5 is open and is airtightly connected with the upper opening of the inner cavity of the test piece groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com