developer cartridge

A developer box and box body technology, which is applied in the field of developer boxes, can solve the problems of short time, poor reset effect, and inability to realize sensor time interval, etc., and achieve the effect of prolonging contact time and realizing delayed detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

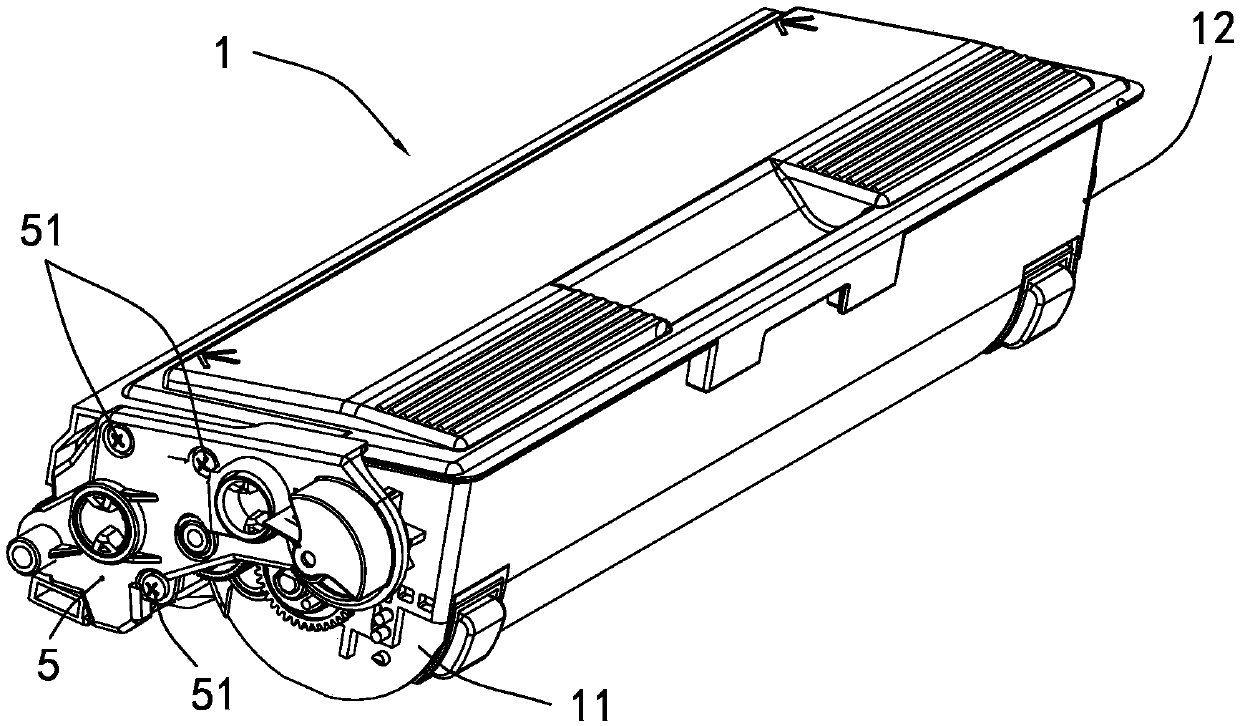

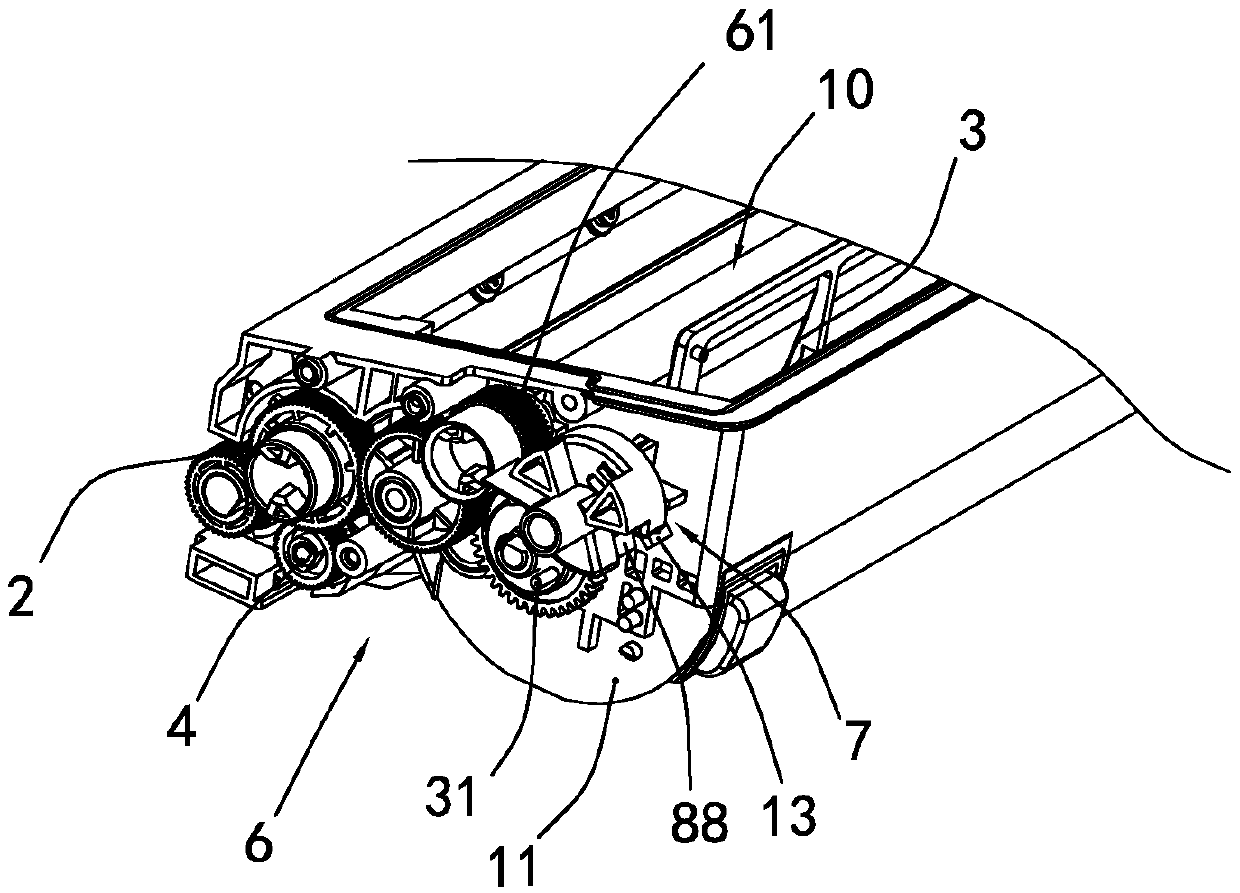

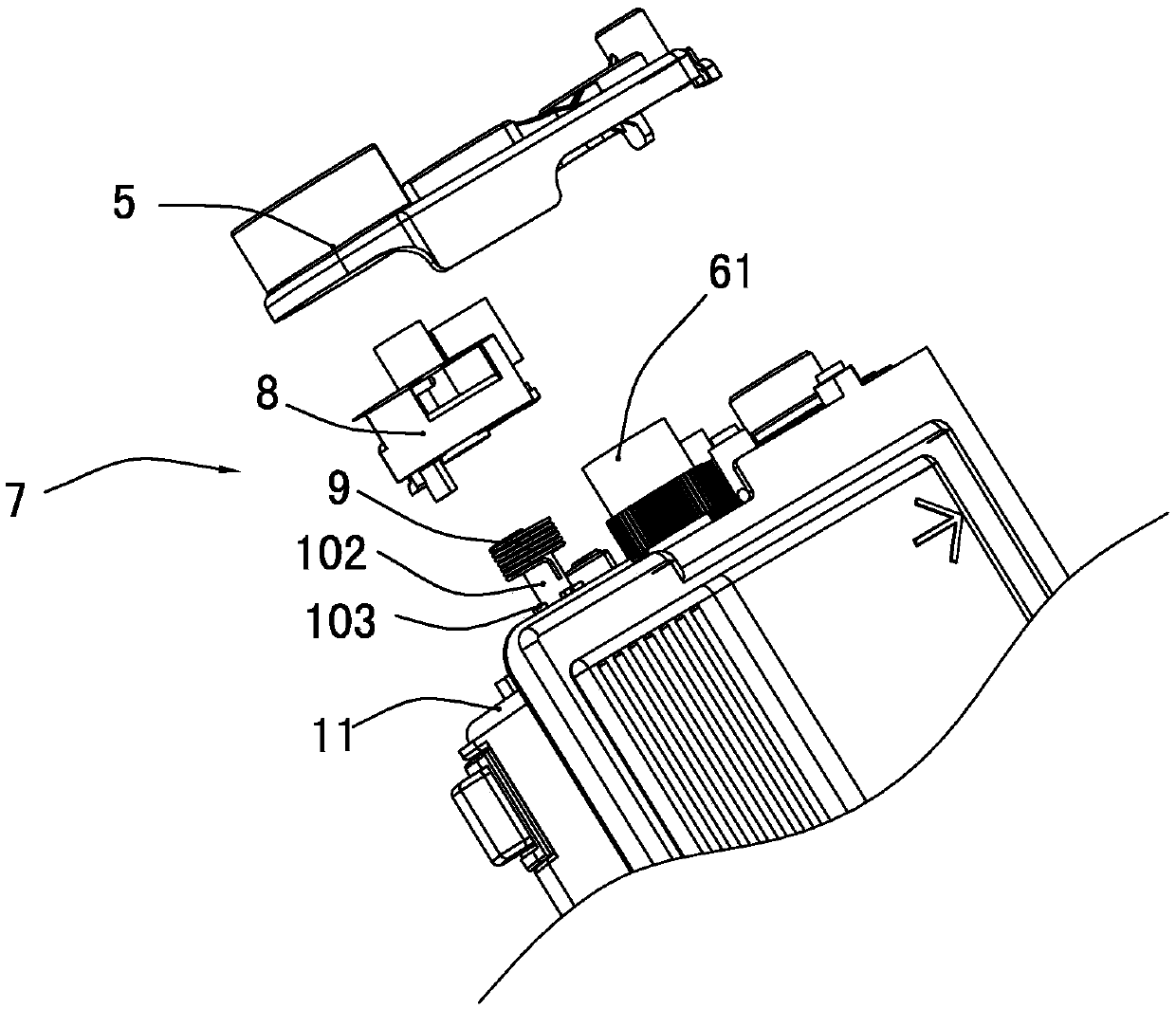

[0025] see figure 1 and figure 2 , the developer cartridge of the present invention is used in image forming equipment such as laser printers, and it includes a box body 1 surrounded by a first end wall 11, a second end wall 12, and a plurality of side walls. The inside of the box body 1 is divided into storage The toner storage bin 10 of a rated amount of developer and the development bin used to store a certain amount of developer and complete the adsorption of the developer on the surface of the developing roller 2 (only the end is shown). There is a powder feeding roller 4 that supplies developer to the developing roller 2 between the developing chamber and the developing roller 2 and the powder feeding roller 4 are rotatably supported on the two end walls of the box body 1. A powder knife (not shown) for the thickness of the developer layer on the surface of the developing roller. The first end wall 11 of the box body 1 is provided with a gear transmission mechanism 6,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com