Capacitive touch screen of single glass structure and production technology thereof

A technology of structural capacitance and monolithic glass, which is applied in the direction of electrical digital data processing, instruments, and data processing input/output process, and can solve the problems of low production yield, high cost of capacitive touch panel, and high cost. Achieve the effect of high yield rate, improve product technology level and value, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

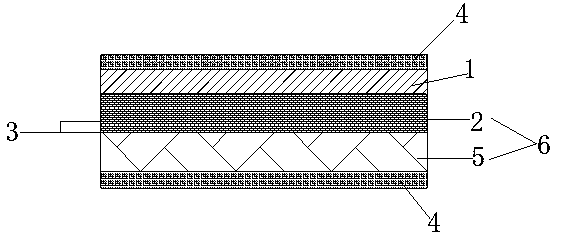

[0027] Such as image 3 As shown, a monolithic glass capacitive touch screen (OGS), including a small piece of glass white substrate 1, a touch electrode layer 6 and a flexible circuit board (FPC) 3, on the small piece of glass white substrate The window area of sheet 1 is plated with ITO conductive film 2, and the PET protective film 4 is pasted on the ITO surface; the ITO glass is wet-etched according to the designed electrode pattern, and Ag wire and gold finger (belonging to image 3 The silver paste circuit layer 5) in the film forms the touch electrode layer 6; the ITO glass is connected with the flexible circuit board (FPC) 3 through the binding process with conductive glue, and then conducts with the touch IC to generate touch function; The surface of the IC in the component area is pasted with insulating tape.

[0028] Such as Figure 4 As shown, a production process flow chart of a monolithic glass structure capacitive touch screen (OGS), the specific steps are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com