Motor rotor for preventing rotor winding from being thrown out

A rotor winding and motor rotor technology, applied in the direction of magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the problems that the rotor winding is easy to break and be thrown out due to no weft tape, and the effect is obvious. The effect of improving reliability

Inactive Publication Date: 2013-11-20

永济中车电机电器修配有限公司

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] In order to solve the problem that the rotor winding is easily thrown out when the rotor rotates at high speed due to the easy breakage of the weft-free tape, the invention provides a motor rotor that prevents the rotor winding from being thrown out.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

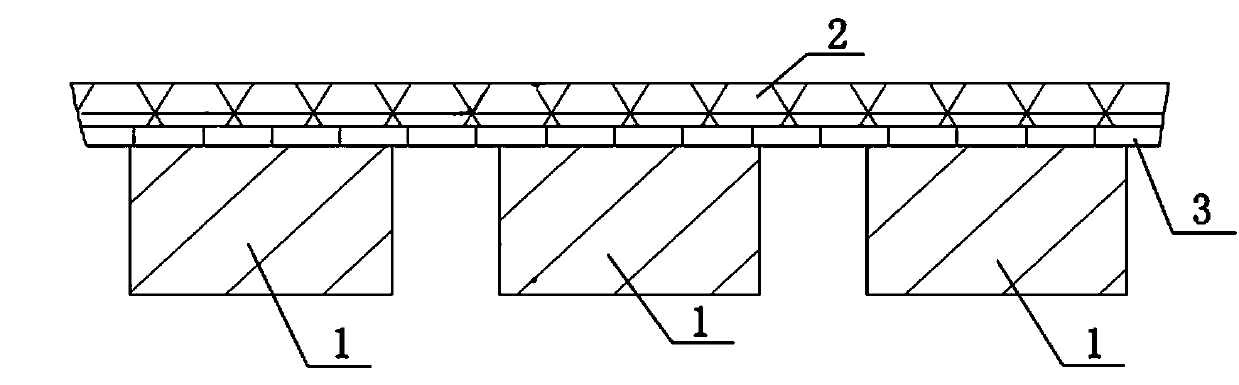

[0010] A motor rotor that prevents the rotor winding from being thrown out, including a rotor winding 1 wound on the rotor, two ends of the rotor winding are bound with latitude-free tape 2, and a glass ribbon layer 3 is arranged between the end of the rotor winding and the latitude tape , During specific implementation, the end of the rotor winding is firstly punched with a glass ribbon, and a non-weft tape is stamped on the glass ribbon.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a direct-current motor and a winding type alternating-current motor rotor, in particular to a motor rotor for preventing a rotor winding from being thrown out, which is used for solving the problem of easiness in throwing away rotor windings during high-speed rotation of the rotor due to breakage of weftless tapes. The motor rotor for preventing the rotor windings from being thrown out comprises rotor windings wound on the rotor, wherein weftless tapes are tied at the two ends of the rotor windings; glass tape layers are formed between the end parts of the rotor windings and the weftless tapes, and fill the gaps among the rotor windings; the welftless tapes are fully contacted with the glass tape layers; the contracting degrees of the weftless tapes are the same during glue removal; and the surfaces of the weftless tapes are smooth and flat without any crack, so that the reliability of the welftless tapes is improved greatly, and a remarkable effect is achieved. The same motor rotor without the glass tape layer has the defects of a large quantity of cracks on the weftless tapes. The motor rotor is detached, the glass tape layers and the weftless tapes are formed in sequence, and drying and cooling are performed, so that the surfaces of the weftless tapes are smooth and flat without any crack, the reliability of the welftless tapes is improved greatly, and a very remarkable effect is achieved.

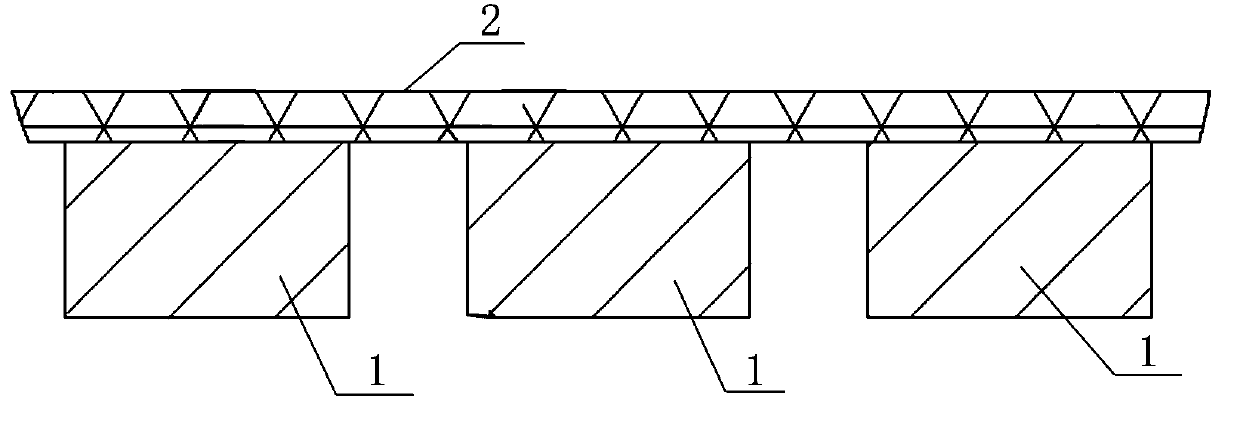

Description

technical field [0001] The invention relates to a DC motor and a wound AC motor rotor, in particular to a motor rotor that prevents the rotor winding from being thrown out. Background technique [0002] The rotors of DC motors and wound AC motors include rotor windings wound on the rotors. The two ends of the rotor windings extending out of the iron core are also bound with latitude-free tapes. The latitude-free tapes can prevent the rotor windings from being thrown out when the rotor speed is too high. Therefore, the weft-free tape bound at the end of the rotor winding is particularly important. The structure of the existing no weft tape binding rotor winding is as follows: figure 1 As mentioned above, the latitude-free tape bound at the end of the rotor winding is directly in contact with the end of the rotor winding; while the surface of the inclined part of the end of the rotor winding is not smooth, and there are gaps between the rotor windings, causing some latitude-f...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H02K1/28

Inventor 王世玉王鑫卫文改韩建霞冯翠萍

Owner 永济中车电机电器修配有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com