10.5kV 4100-meter high-altitude hydro-generator insulation structure

A technology of hydroelectric generator and insulation structure, which is applied to the shape/style/structure of winding insulation, which can solve the problems of shortening the operating life of the unit and the partial discharge of the coil, so as to improve the stator insulation structure and anti-corona structure, Effect of reducing air gap and internal discharge and prolonging operating life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

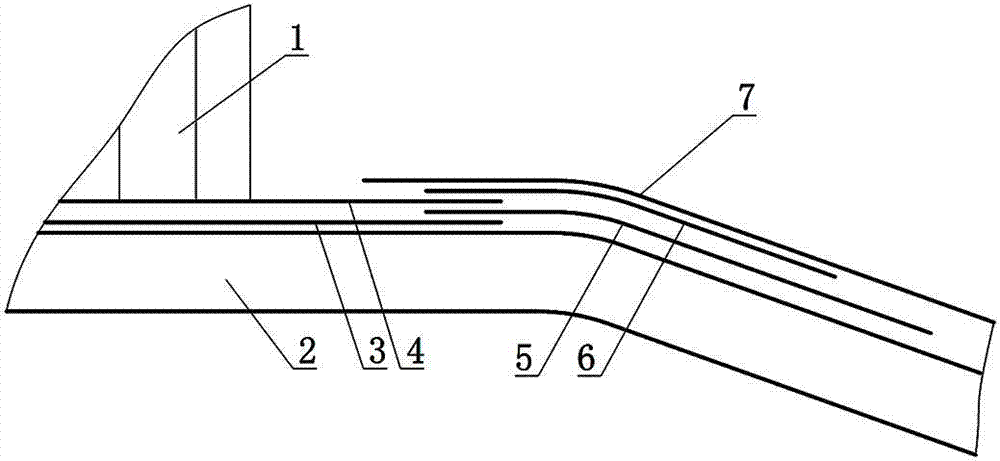

[0016] Such as figure 1 As shown, the insulation structure of a 10.5kV class 4100-meter high-altitude hydro-generator includes an iron core 1 and a coil 2. The outer surface of the coil 2 is provided with low resistance along the direction from the side near the end of the wire slot to the terminal of the coil 2. Structure and high resistance structure, the low resistance structure includes a low resistance band 3 wrapped on the outer surface of the coil 2 and a low resistance paint layer 4 coated on the outer surface of the low resistance band, the high resistance structure is included in the coil 2 The high-resistance band 5 wrapped on the outer surface and the high-resistance paint layer 6 coated on the outer surface of the low-resistance band overlap the edges of the high-resistance structure and...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap