Motor combined hermetically-sealed structure

A sealed structure and combined technology, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of motor failure, shortened life of seals, and easy water ingress of the motor, so as to achieve convenient installation and replacement, prolong service life, Enhanced sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

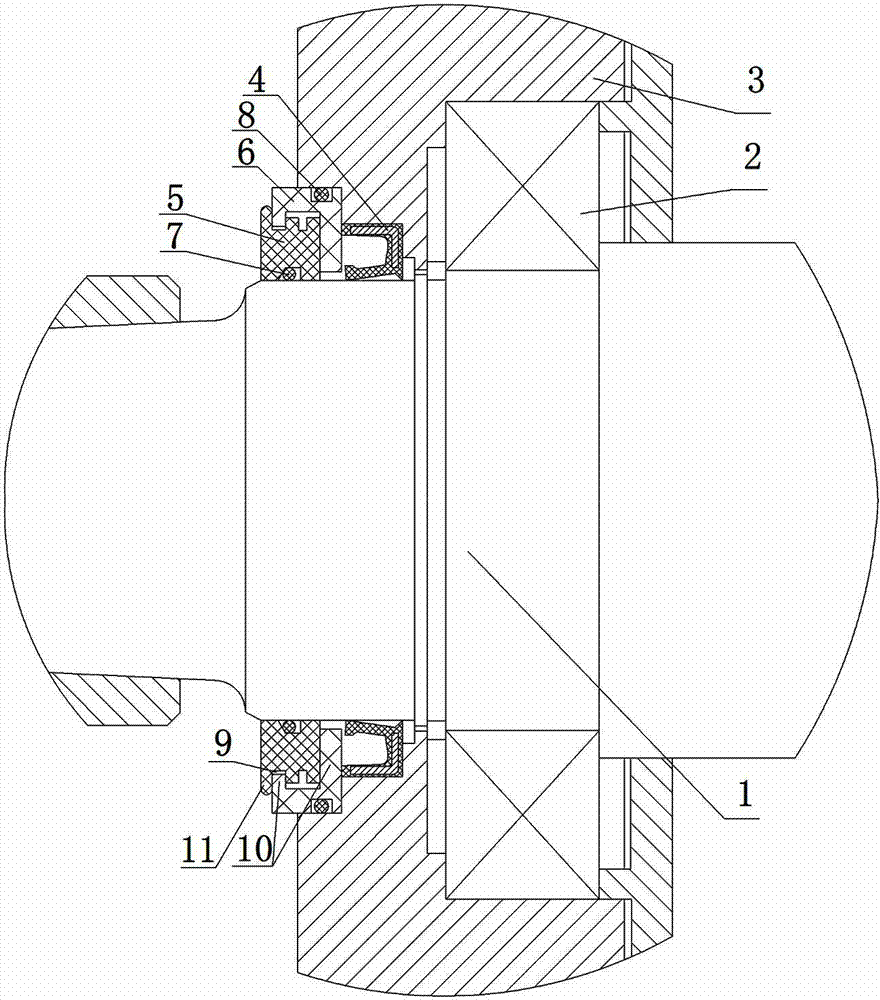

[0012] Such as figure 1 As shown, the combined sealing structure of the motor includes the shaft extension end 1 and the end cover 3 of the rotor. The shaft extension end 1 is installed on the end cover 3 through the bearing 2, and a skeleton seal is arranged between the end cover 3 and the shaft extension end 1. 4. A dynamic seal is provided between the axially outer end cover 3 of the skeleton seal 4 and the shaft extension end 1, and the dynamic seal includes a dynamic seal ring 5 arranged on the side of the shaft extension end 1 and a dynamic seal ring 5 arranged on the end cover 3 The static sealing ring 6 on the side, the O-ring A7 is set between the dynamic sealing ring 5 and the shaft extension end 1, the O-ring B8 is set between the static sealing ring 6 and the end cover 3, the dynamic seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com