Method for accurately controlling water intake, material quantity detection method and pulping method for soybean milk machine

A precise control, soymilk machine technology, applied in dairy products, beverage preparation devices, milk substitutes, etc., can solve the problems of small space pulverizers, small volume, high water and material accuracy requirements, and deviation of pumping speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

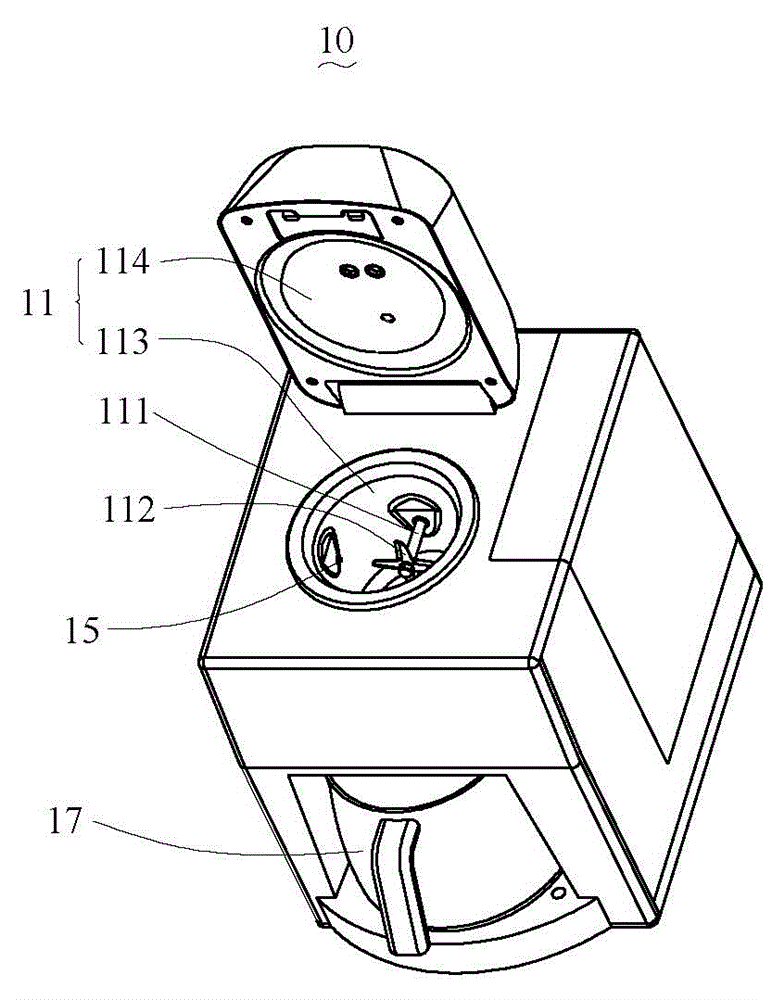

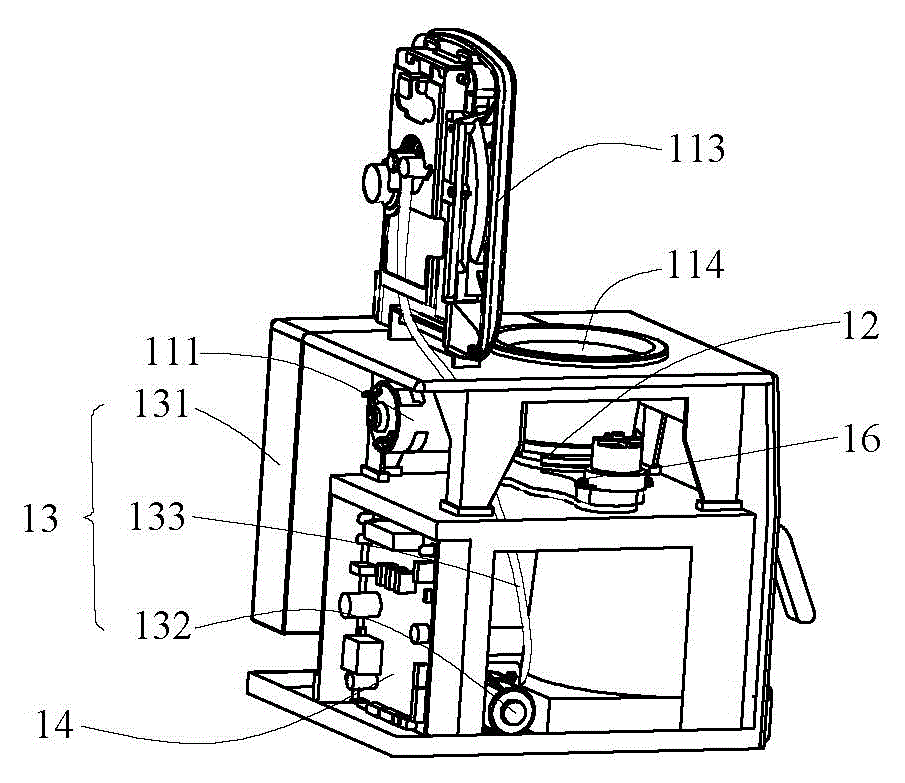

[0032] see figure 1 and figure 2 The first preferred embodiment of the soymilk machine 10 on which the method of the present invention is based, the soymilk machine 10 includes a small space grinder 11, a motor 111, a crushing cutter 112, a heating element 12, a water supply mechanism 13 and a circuit control unit 14. The motor 111 drives the crushing tool 112 to rotate. The heating element 12 is set on the small space pulverizer 11. The small space pulverizer 11 is provided with a water level sensor 15. The water level sensor 15 is set at the nominal water volume. A slurry discharge valve 16 is also provided at the bottom of the space pulverizer 11, and a pulp receiving cup 17 is arranged below the slurry discharge valve 16. The water supply mechanism 13 includes a water tank 131 and a water pump 132. The water tank 131, the water pump 132 and the small space pulverizer 11 pass through the water pipe. 133 , the motor 111 , the heating element 12 , the water level sensor 15 ...

Embodiment approach 2

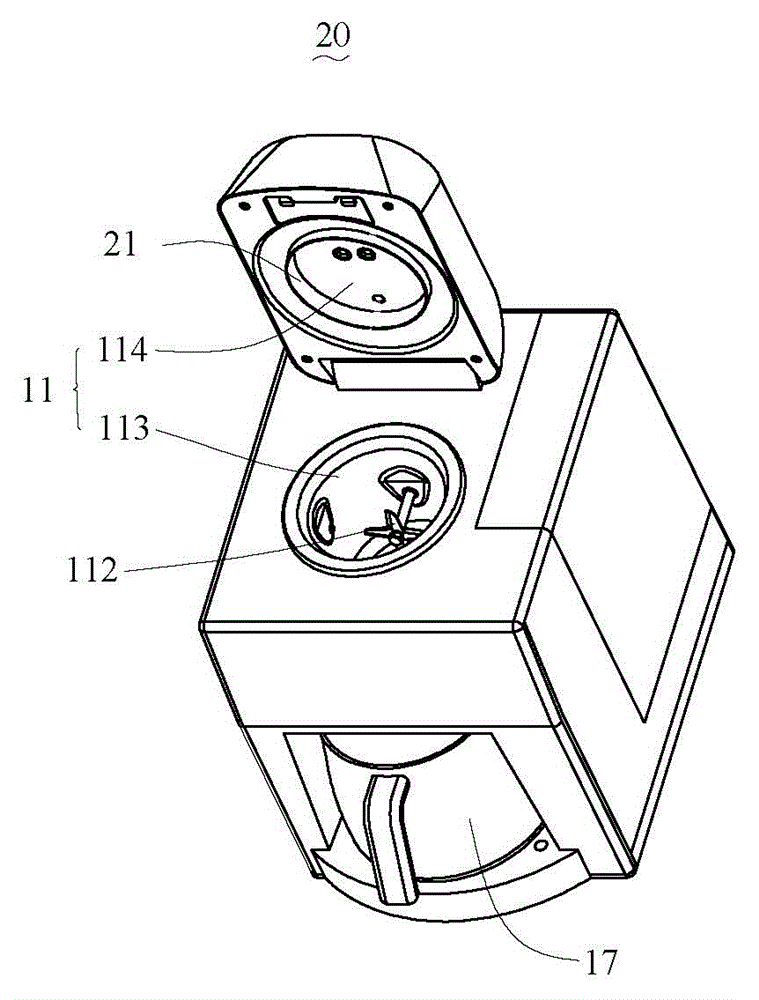

[0050] see image 3 and Figure 4 , the second preferred embodiment of the soymilk machine 20 on which the method of the present invention is based differs from the first embodiment in that a sealing ring 21 is arranged between the cylinder body 113 and the cylinder head 114, and the cylinder head 114 is provided with a breather valve 22, and this small space pulverizer 11 can form an airtight space. When water was poured into the small space pulverizer 11, the vent valve 22 was opened; when starting to make soybean milk, the vent valve 22 was closed, and the small space pulverizer 11 formed an airtight space.

[0051] The pulping method is slightly different from Embodiment 1, and the pulping procedure in the step (3) includes:

[0052] a. Preheating step: close the ventilation valve 22, the small space pulverizer 11 forms an airtight space, and then the heating element 12 heats the water and materials in the small space pulverizer 11 to a set temperature value;

[0053] b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com