Self-alignment shaft head clamping mechanism

A technology of clamping mechanism and positive shaft, which is applied in the direction of metal rolling stand, metal rolling mill stand, metal rolling, etc. It can solve the problem of difficult adjustment of the position of the shaft head of the supporting plate and the universal coupling, and the in-out shaft of the work roll. The problems such as head difficulty can be solved to achieve the effect of flexible and effective adjustment, saving the time of changing rolls and eliminating installation errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

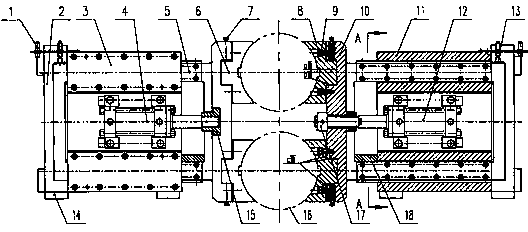

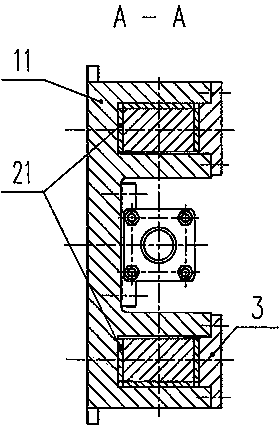

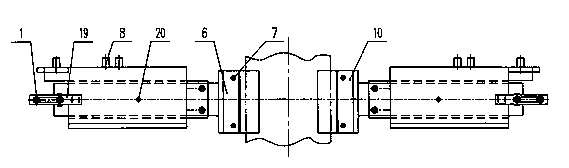

[0020] The structural principle and working principle of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0021] refer to figure 1 , figure 2 , image 3 , Figure 4 , a self-aligning shaft head clamping mechanism, the standard oil cylinder 4 is fixed on the left fixed block 2, and is threadedly connected with the left bracket 5, and the part of the left bracket 5 extending to both sides parallel to the standard oil cylinder 4 is located on the left In the groove of the fixed block 2, and in sliding contact with the left fixed block 2. The adjustment oil cylinder 12 is fixed on the right fixed block 11, and is threadedly connected with the right bracket 10, and the right bracket 10 is located in the groove of the right fixed block 11 in the groove extending to the both sides of the right bracket 10 parallel to the adjustment oil cylinder 11, and is fixed with the right Block 11 is in sliding contact. The standard oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com