Double-mandrel direct-connection precise rotating shaft

A rotating shaft, precision technology, applied in metal processing equipment and other directions, can solve the problems of high price of precision rotating shaft, restricting independent projects, long supply cycle, etc., to achieve compact structure, good force transmission characteristics, and low development cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The embodiment given below intends to further illustrate the present invention, but can not be interpreted as the restriction to protection scope of the present invention, those skilled in the art still belongs to the protection of the present invention to some non-essential improvements and adjustments of the present invention according to the content of the present invention scope.

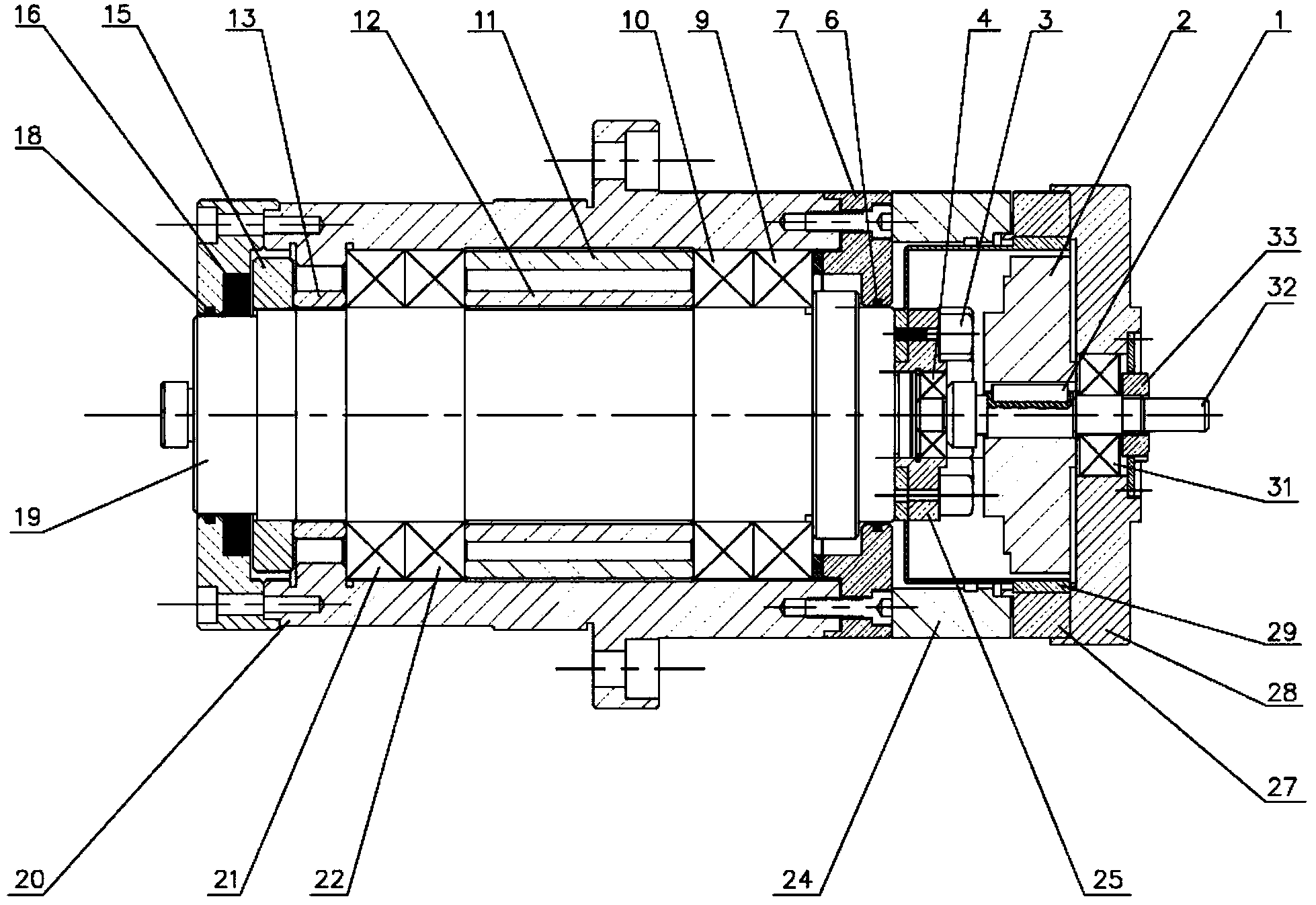

[0018] Two-axis direct-coupled precision rotary axis, such as figure 1 As shown, the rotating shaft has two shafts of the main spindle 19 and the spindle 32, and the inner bearing 4 is fixedly installed on the journal of the big end of the spindle 32, and the inner bearing 4 is fixed in the mounting hole in the fastening collar 25, and fastened The lower surface of the collar 25 fits the flex spline 29 of the harmonic reducer, and is directly connected to the big end of the main spindle 19 through the screw 3 . The flexible wheel 29 of the harmonic reducer meshes with the rigid wheel 27 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com