Automatic die cutter of injection nozzle

A technology of automatic punching machine and nozzle, which is applied in metal processing and other directions, can solve the problems of high production cost and low production efficiency, and achieve the effect of improving production efficiency, reducing production cost and reducing manual picking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. The following embodiments are explanations of the present invention, and the present invention is not limited to the following embodiments.

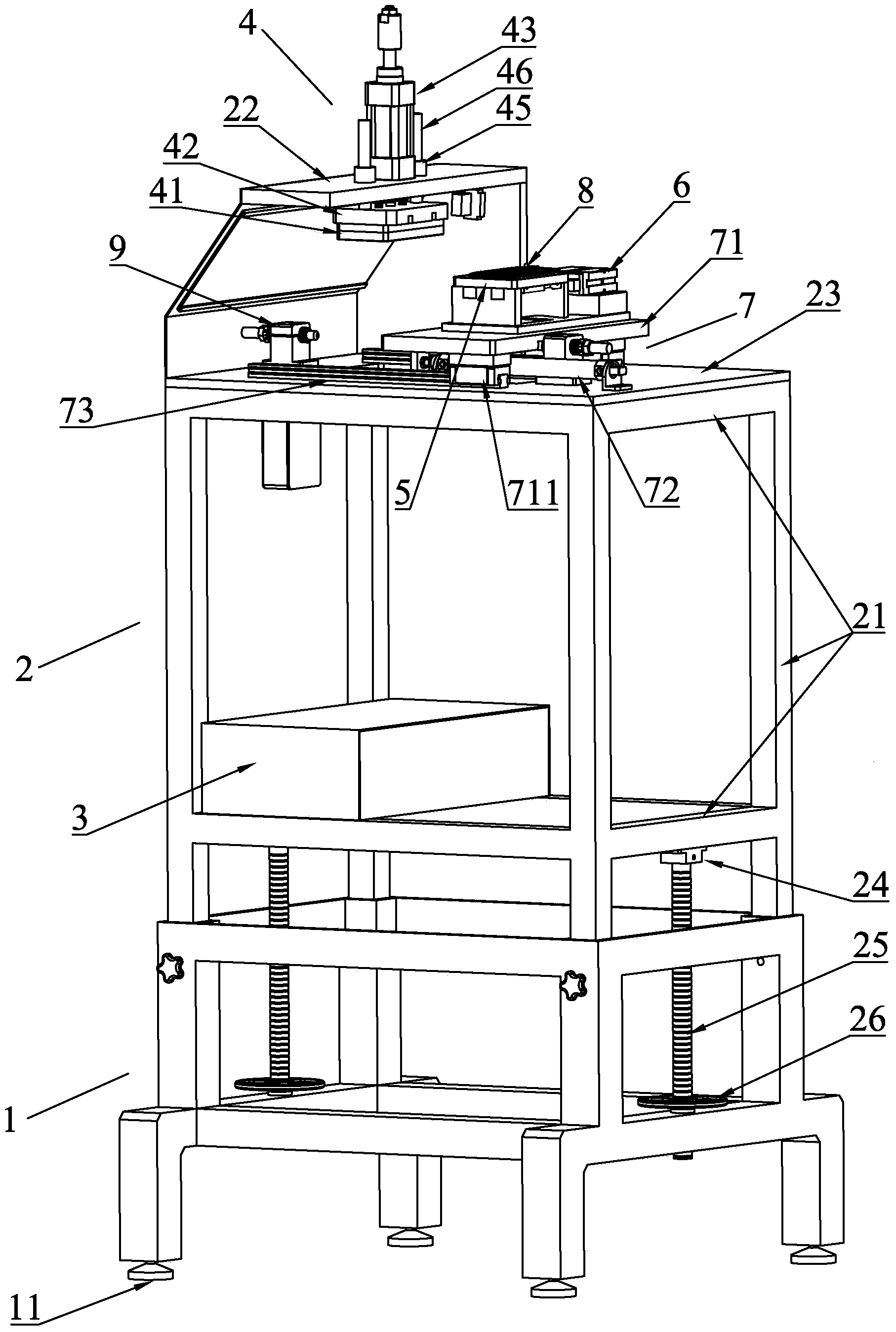

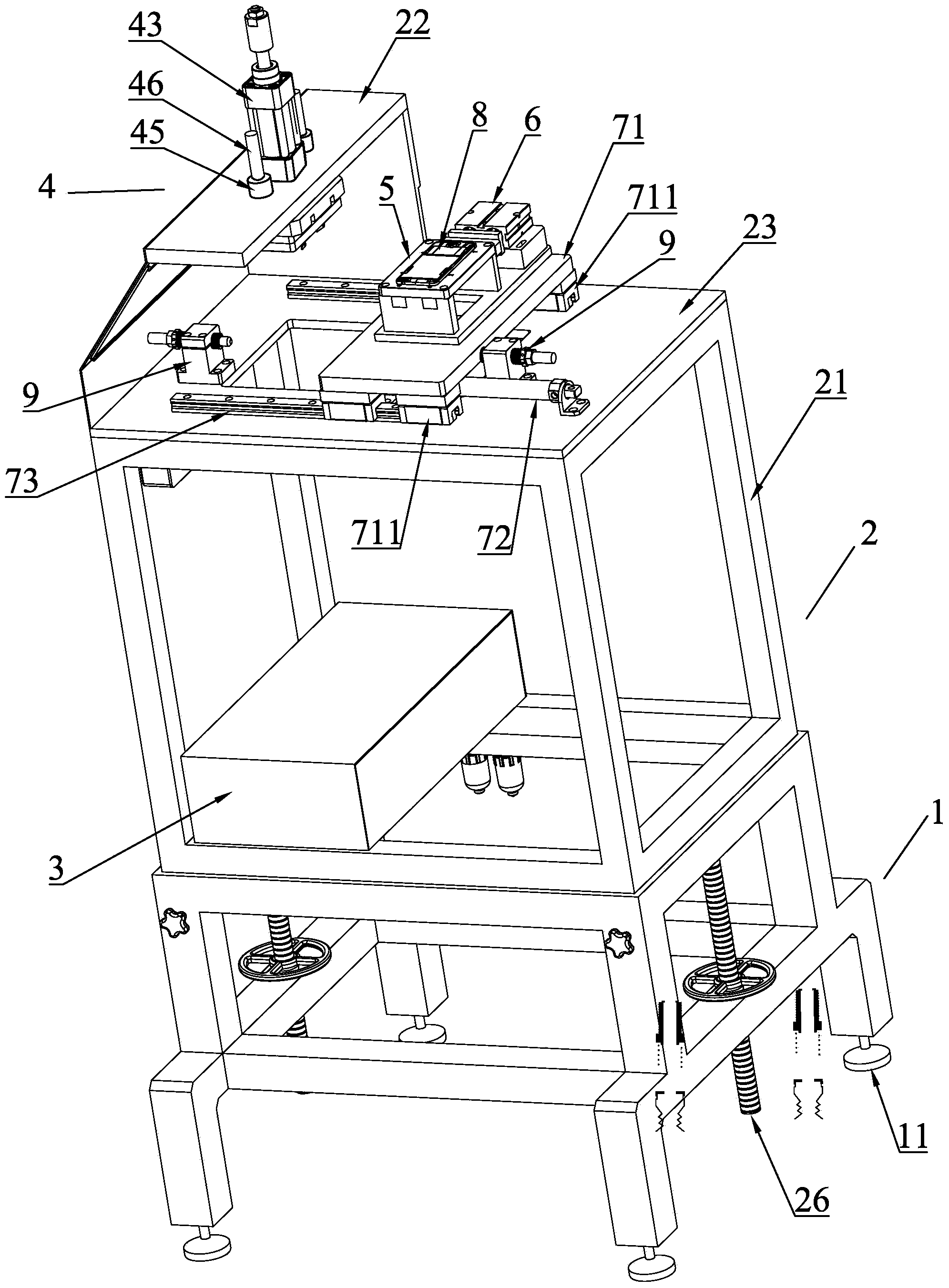

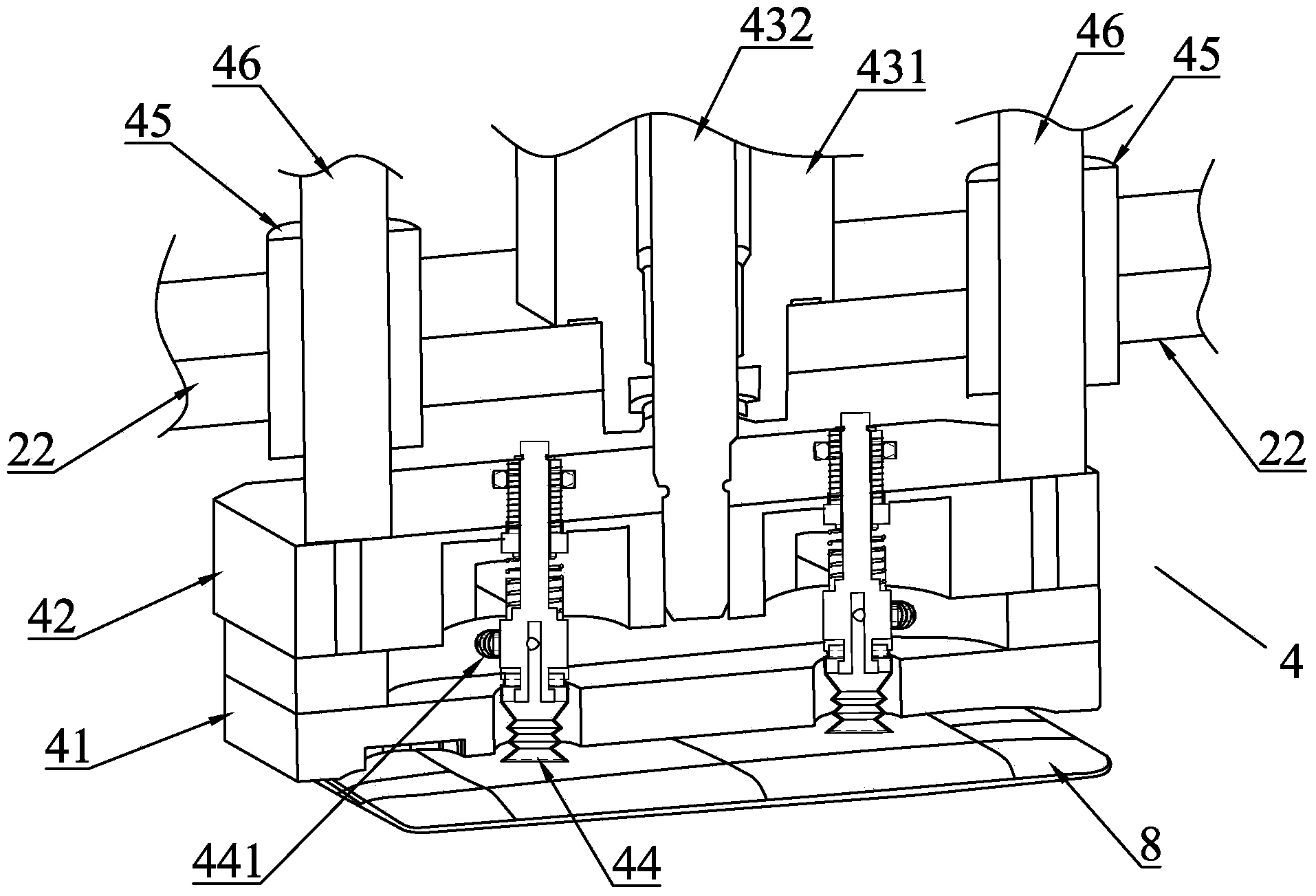

[0022] Such as figure 1 and figure 2 As shown, it is a three-dimensional structural schematic diagram of an automatic punching machine for removing the injection nozzle of a mobile phone case. The automatic punching machine in this embodiment mainly consists of a base 1, a frame 2, a control device 3, a pressing device 4, and a jig The lower die 5, the punching device 6 and the lower die moving device 7 are composed. Wherein, the bottom of base 1 is provided with leg 11; Frame 2 is erected on base 1, and frame 2 comprises support corrugated 21 and is located on the first platform 22 and the second platform 23 along the horizontal direction on support corrugated 21, The first platform 22 is arra...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap