Output device for fully automatic drilling machine for fasteners

An output device, fully automatic technology, applied in the directions of transportation and packaging, conveyors, conveyor objects, etc., can solve the problems of time-consuming and laborious, messy fasteners, etc., to improve work efficiency and reduce labor burden.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

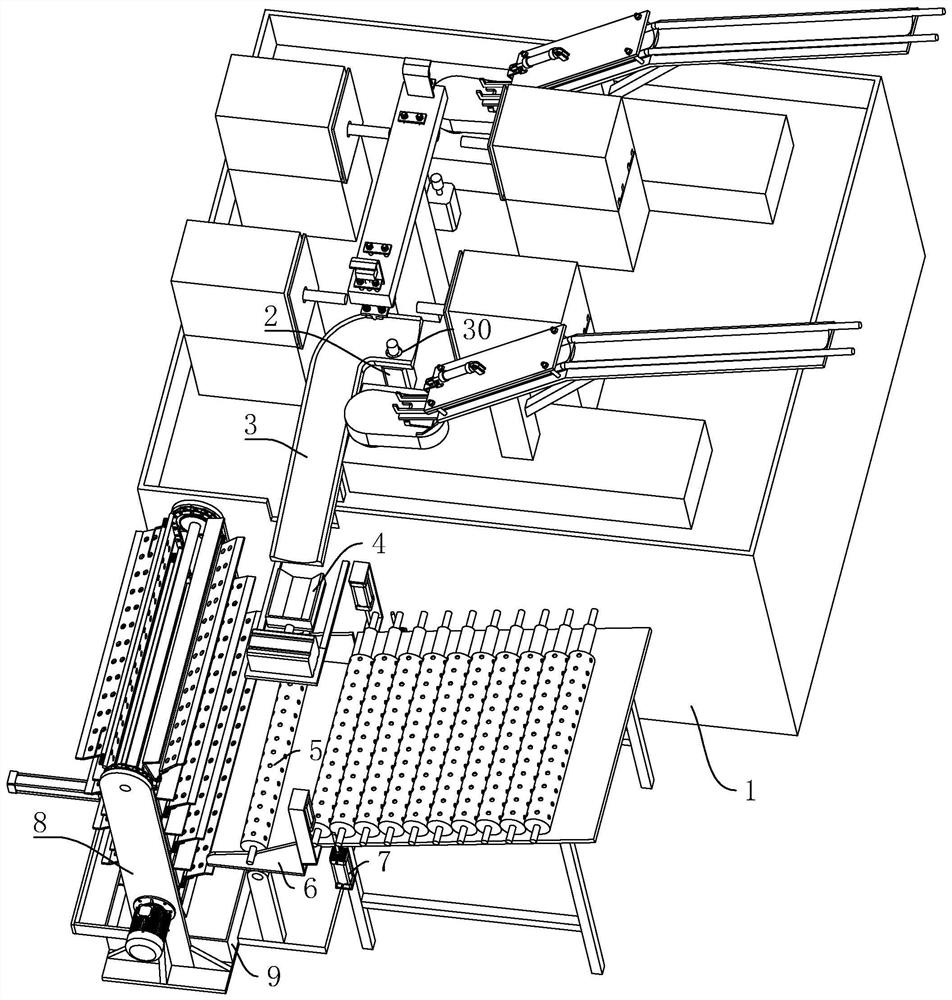

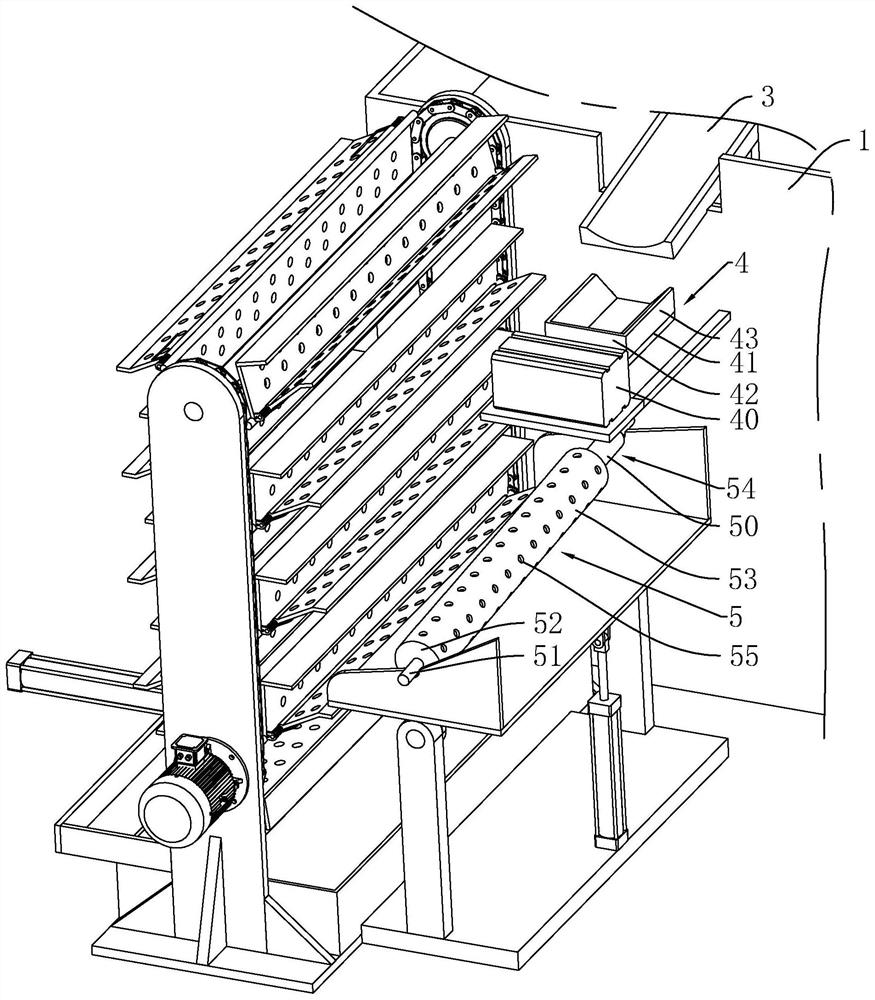

[0042] refer to figure 1 , a kind of output device that is used for fastener fully automatic drilling machine, it comprises frame 1, is respectively arranged on the frame 1 for the cylinder rod of clamping cylinder 2 to pass through the feeding slide 3, is arranged on the feeding The slide plate 3 is away from the turning assembly 4 at one end of the clamping cylinder 2, the slide rod 5, the push rod assembly 6 arranged below the slide rod 5 and used to rotate the slide rod 5, and the push rod assembly 6 used to transport the slide rods 5 to the top one by one. The conveying assembly 7 on the rod assembly 6, the collecting assembly 8 for conveying the sliding material rod 5, and the collecting assembly 9 arranged below the collecting assembly 8 and used for collecting the sliding material rod 5;

[0043] refer to figure 1 , the feeding slide 3 is L-shaped, and the cross-sectional shape of the feeding slide 3 is similar to several fonts. One end of the feeding slide 3 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com